The UK is launching a new initiative to develop the next generation of sustainable composite materials and bring together the UK’s composites expertise to transform research breakthroughs into industrial applications, such as for wind turbine blades.

Sustainable Composites is led by the National Composites Centre (NCC) and the Centre for Process Innovation (CPI) and is a partnership between industry, academia and government that will harness the UK’s world-leading composites research and technology development capabilities.

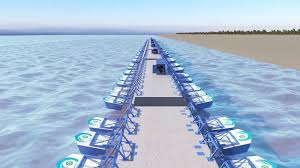

Composites are in high demand by manufacturers developing the next generation of lightweight, super energy-efficient planes, cars and wind turbines, the initiative said.

Compared with metals and other materials, composites are lighter, stronger, more durable, longer-lasting, and allow more flexibility in design, but about 85% of these materials are not being re-used or recycled at the end of their life.

In renewables, Europe’s first wind farms were built over three decades ago, and these produce roughly 180 times less energy at more than twice the cost per kWh than modern equivalents, the initiative said.

“Consequently, an increasing number of older turbines are being decommissioned, and growing quantities of end-of-life composites waste produced,” it added.

There are currently significantly limited commercial recycling routes for wind turbine blades in the UK, and very few options in Europe as a whole.

Sustainable Composites is set to address this challenge by accelerating the development of new recycling technologies in the UK while simultaneously creating new sustainable composites made from bio-based materials including vegetable waste, corn, nutshells and algae.

It aims to deliver a series of R&D projects that bring together companies across the composites supply chain – from materials manufacturers, to chemical suppliers, manufacturers, and recycling companies.

The projects aim to identify and mature new technologies, investigate new material feedstock, and develop the product design and manufacturing processes that enable these new materials to quickly enter the supply chain and be successfully recycled at the end of their life.

NCC chief executive Richard Oldfield said: “We have the expertise in the UK to take the lead in developing the technologies and processes that make composite materials a net zero carbon alternative.

“We need to accelerate that innovation and lock-in sustainability from design to end-of- life – and that’s where the NCC can help.

“By joining forces with CPI in this initiative, we are bringing together our engineers, our technologies and our network of universities and companies to build a robust supply chain in the UK.”

Sustainable Composites programme lead Ed Goodman said: “Composites are already supporting sustainability and helping companies meet their low carbon goals by dramatically reducing weight without impacting their performance, enabling critical renewable energy sources.

“Composites are making aircraft more fuel efficient, increasing the range of electric vehicles, and helping companies build huge wind turbine blades to power our homes.

“This initiative will harness our world-leading composites research and technology capabilities to make zero impact composites a reality.

“And it will ensure the UK continues to lead the way in sustainable materials and capitalise on the huge opportunities for recycling of valuable materials to protect our precious resources for future generations.”