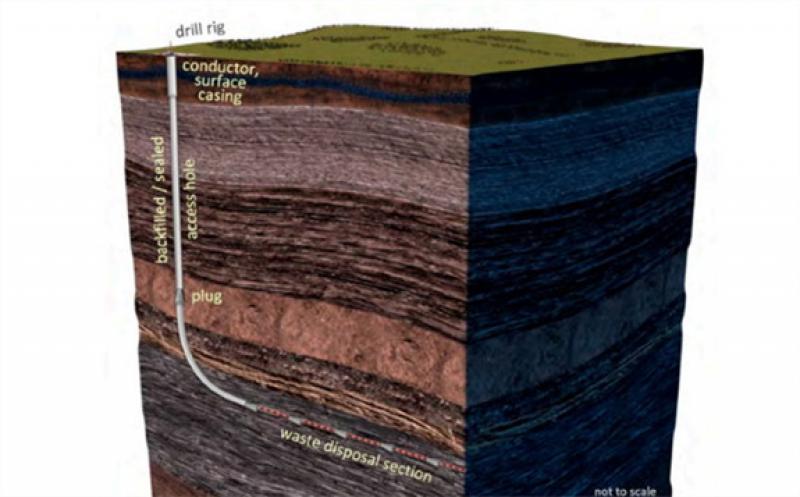

Deep Isolation's concept for the disposal of nuclear fuel and high-level waste (Image: Deep Isolation)

Berkeley, California-based Deep Isolation has developed a solution for the management of used nuclear fuel and high-level radioactive waste (HLW) by emplacing it in corrosion-resistant canisters placed in deep horizontal drillholes. The latest agreement will see NAC engineer, license and deliver the canisters and other equipment associated with the handling and transferal of high-level waste, used nuclear fuel and other nuclear waste from existing storage areas to a Deep Isolation repository. The agreement includes an in-kind commitment by NAC for its services.

"As we approach the milestone of licensing a disposal facility, we have an internal team focused on the process of moving the spent fuel from its current storage state, transferring it to a Deep Isolation canister and into the drillhole," said Deep Isolation CEO Elizabeth Muller. "This is a non-trivial challenge that requires the highest standards of safety and precision, and we are making great strides. The disposal canister design and NAC's expertise with spent fuel handling are essential to this work, and we are excited to sign this long-term agreement between Deep Isolation and NAC."

NAC, a wholly-owned subsidiary of Hitachi Zosen Corporation, has supplied a "large share" of the used fuel systems in use at decommissioning US utility sites, and has also developed and deployed transportable storage systems for use at US Department of Energy (DOE) sites, the companies said.

"Collaborating with Deep Isolation to create a much-needed new solution for spent nuclear fuel and high-level waste management demonstrates our commitment to developing and delivering innovative new technologies that has made NAC a trusted partner for fuel cycle solutions for over 50 years," said Kent Cole, president and CEO of NAC International. "This new long-term agreement enables our two companies to work more closely and effectively together to combine unique and valuable technologies to provide this game-changing option for our customers around the world."

In June last year, Deep Isolation signed a cooperative agreement with Bechtel National, Inc on sales, product development and deployment of Deep Isolation's patented technology. Under that agreement, Bechtel is to provide support such as project management, financial/business and engineering capability for Deep Isolation's sales in both domestic and international markets, including those with the DOE, with Deep Isolation providing options to support Bechtel's cleanup work at US federal government sites.

Deep Isolation's drillhole approach involves the emplacement of waste in corrosion-resistant canisters - typically 9-13 inches (23-33 centimetres) in diameter and 14 feet (4.3 metres) long - into horizontal drillholes deep in rock that has been stable for tens to hundreds of millions of years. A vertical access section - which could be a few thousand feet to a few miles deep, depending on the geology - gradually curves to form a nearly horizontal disposal section which could be up to 2 miles long.

Once the waste is in place, the vertical access section of the drillhole and the beginning of its horizontal disposal section are sealed using rock, bentonite and other materials, although the canisters can still be retrieved if necessary. According to Deep Isolation, the key advantages of this method are the depth of burial and the fact that the waste is stored in a suitable geologic formation far below the water table, in rock that is saturated with brine that has no commercial value and has been virtually stagnant for millions of years. In addition, the small diameter drillholes require less disturbance of the rock than a mined repository.