As part of an effort to address the gap the U.S. Army faces in the need for long-lasting power and batteries for warfighters, the Army Research Office funded a research team who developed an artificial intelligence system that officials say identifies a promising material for creating more efficient fuel cells.

Researchers said the system, developed at Cornell University, is a potential breakthrough in both materials science and machine learning. It relies on a collective of algorithmic bots each performing a distinct task and sifts through hundreds to thousands of combinations of elements to create a map of phases — arrangements of atoms in relation to each other — that humans can then use to determine which might work as a new material.

“The exciting part about basic science research is you can’t always predict where the results will lead,” said Dr. Purush Iyer, division chief, network sciences at Army Research Office, an element of the U.S. Army Combat Capabilities Development Command’s Army Research Laboratory. “We funded this research to better understand collective intelligence (wisdom of crowds). While material science application, such as design of novel alloys, were always on the cards, the serendipitous nature of the eventual outcome, that of a catalyst to aid in designing better fuel cells, is solving a problem of immense importance for the Army — battery power in the field — shows the importance of investing in basic research.”

The problem forced researchers to develop a whole new approach, they said.

“[It] really pushes the frontier of AI to derive physically meaningful solutions,” said Dr. Carla Gomes, professor of computer science and director of the Institute for Computational Sustainability, and first author of the paper published in June in Materials Research Society Communications.

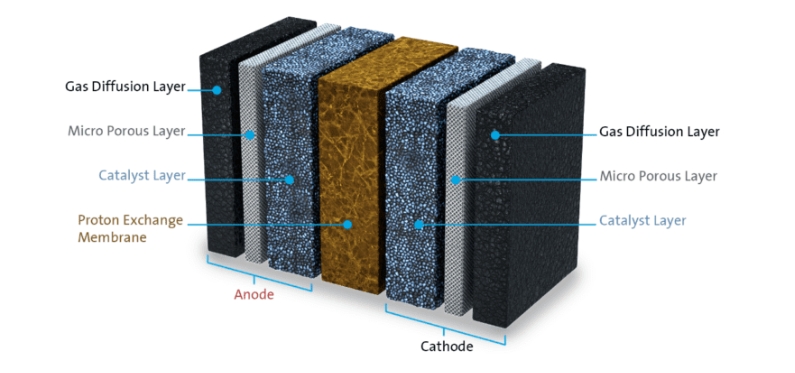

Researchers seeking to improve fuel cells for cars are searching for a catalyst that would allow them to replace hydrogen, which is difficult to store, with methanol, which could be far more efficient. But because no known materials are efficient catalysts for methanol oxidation, a new material is needed, said co-author John Gregoire, Ph.D., a staff scientist at the California Institute of Technology.

“If a viable catalyst exists, it’s going to need to be discovered by combining elements of the periodic table, and the number of combinations is so vast that it can’t be done with traditional experimentation,” Gregoire said.

Researchers also need to understand the crystal structure, or phase, of the material, because solids may have multiple phase structures and each one behaves differently as a catalyst.

“Humans can solve the phase map for simple composition systems containing two elements,” Gregoire said, “but whenever there are more than two elements, it’s too much information for humans to process, and we need AI to assist.”

Existing machine learning approaches, however, were not well suited for the strict constraints of scientific discovery, in which solutions must not only be plausible but also obey the laws of physics and chemistry, Gomes said.

To meet the challenge, Gomes and colleagues developed a system called CRYSTAL for crystal phase mapping, in which multiple bots each take on a different part of the problem, from predicting the phase structures of various combinations to making sure those predictions obey the rules of thermodynamics.

Gomes said CRYSTAL was inspired partly by the IBM Watson supercomputer, which used a community of AI agents coming up with different possible solutions to beat human champions at “Jeopardy!”

Using the system, researchers were able to identify a unique catalyst, composed of three elements crystallized into a certain structure, which is effective for methanol oxidation and could be incorporated into methanol-based fuel cells.

“This is an important discovery that challenges our understanding of catalysis, and an important research direction toward designing the next generation of catalysts,” Gregoire said.

“The outcome of this research is to make battery power readily, and continuously, available to soldiers in a form that is safe and easily transportable, which could have a huge impact on the lives and performance of our soldiers,” Iyer said.