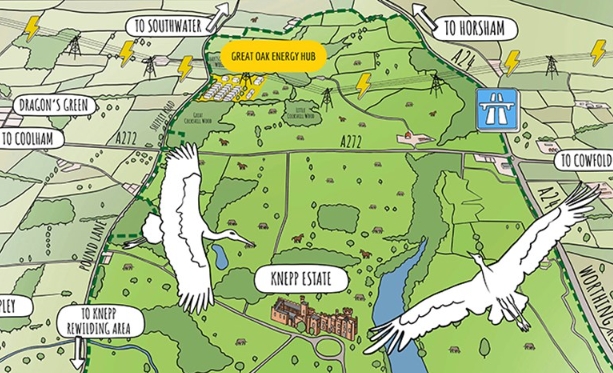

The global renewable energy market is anticipated to grow significantly to around $1.5 billion by 2025 as most countries commit to reducing their greenhouse gas emissions that significantly impact the environment, this is according to Allied Market Research’s Renewable Energy Market Outlook – 2025.

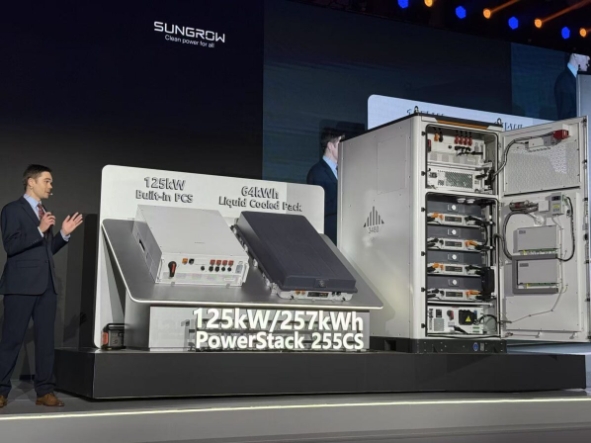

Renewable energy technologies convert energy from natural resources such as the sun or wind into usable forms of electricity that can be used at any time, regardless of changes in weather patterns. This indicates the growth potential for reliable energy storage solutions.

The deployment of energy storage batteries, which are designed to store energy that can be used at a later stage, has increased over the years. Whilst there has been little conversation about the safety of these batteries, the increase in fire incidents reported at energy storage facilities, indicates that open conversations must be had about the safety of energy storage.

When a significant amount of energy is stored, adequate controls must be in place to control the energy output.

In April 2019, an explosion at a 2-MW/2-MW-h solar energy-powered and grid connected battery facility located in Surprise, Arizona, seems to indicate that there is a significant lag in control and operational measures at energy storage battery facilities.

As part of Vanitec’s Energy Storage Committee (‘ESC’) strategic objectives, the ESC is committed to the development and understanding of fire-safety issues related to the Vanadium Redox Flow Battery (‘VRFB’), with emphasis on the solutions the VRFB can provide to the energy storage industry to mitigate fire-risk.

Non degradation, non-flammable, low likelihood of fire:

1.The Vanadium Redox Flow Battery stands out from other batteries due to the favourable characteristics of the vanadium electrolyte (‘electrolyte’), which is used as a solution in both tanks of the battery. The use of the same solution alleviates the possibility of cross-contamination of the electrolyte, therefore eliminating degradation.

2.Over 50% of the electrolyte solution is made up of water, which gives the electrolyte a non-flammable property. In the event of short circuiting, intense heat or high pressure, it is unlikely for the battery to catch fire.

3.Whilst some heat may be discharged from the battery, it will not be at a level that is deemed unsafe.

As is with any development, the Vanadium Redox Flow Battery has faced misconceptions around its cost. The price of vanadium electrolyte is highly dependent on vanadium market prices.

However, the electrolyte can be re-used, ad infinitum, and the vanadium in the electrolyte can be recovered and re-used in a myriad of other applications including as a strengthening alloy for steel. These re-use and recovery options have led to market participants to begin leasing the electrolyte to help manage cost considerations.

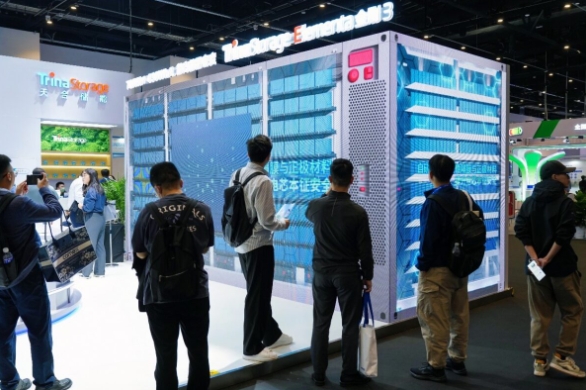

Currently, there are over 100 VRFB installations globally with an estimated capacity of over 209,800 kWh of energy and the use of vanadium in energy storage applications has doubled to 2.1% of the global vanadium consumption in 2018.

Chairman of Vanitec’s ESC, Mikhail Nikomarov commented: “As markets and industries develop, the role of safety starts to play a larger role. This trend is now happening in energy storage where larger quantities of deployments have resulted in increasing incidence of large-scale battery fires, spanning from South Korea to Europe to the United States.

“Safety is becoming more important for companies deploying large batteries. The intrinsic non-flammability of the water-based chemistry of vanadium redox flow batteries makes them ideal for this growing trend, especially in densely populated areas where the safety risk from fire and smoke is greatest. VRFBs thus provide energy storage solutions in any environment without risking injury to employees and fire fighters or damaging surrounding property and equipment.”