Fortum has developed a new method to recycle lithium from rechargeable batteries. The Finnish company calls it a patented “breakthrough technology and a new recovery method” designed to reduce the environmental impact of recycling lithium.

Only Fortum did not disclose details. While the statement makes clear the obvious, growing demand EV needs recycling concepts, making a case for eco-conscious consumers and so on, it remains unclear what the actual procedure and new method will be.

There is talk of the process being more efficient, but Fortum specifies no percentage improvement or efficiency increase, nor a recycling rate of how much material they can recover with the process.

In the general statement, Tero Holländer, Fortum Head of Business Line, Batteries, said: “With our new patented technology, we are able to recover Lithium from EV batteries in a more sustainable way, but we will also have the capabilities to produce battery-grade material on an industrial scale.”

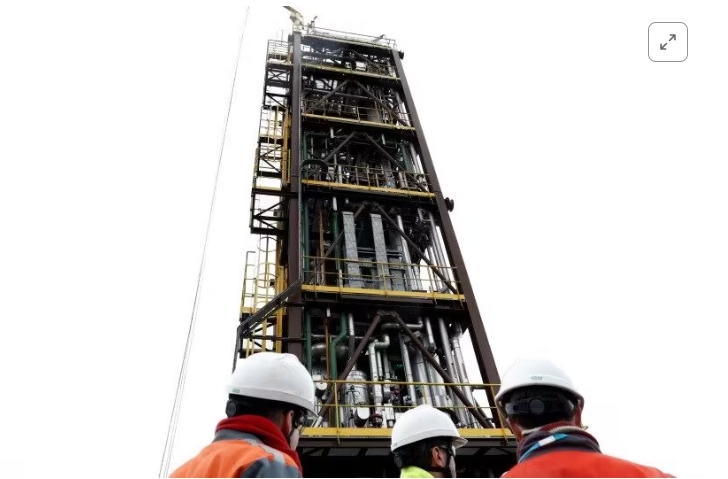

What speaks for Fortum is that the company has made feasible advances in battery recycling before. In March 2019, the company began using a process developed by Crisolteq of Finland, said to recover about 80 per cent of the materials in each battery on an industrial scale. The applied hydrometallurgical process first makes the batteries safe for mechanical treatment by separating plastics, aluminium and copper and feeding them into their recycling processes. Cobalt, manganese, nickel and lithium are then recovered and returned to the battery manufacturers for reuse in the production of new batteries.

Then in March this year, Fortum signed a letter of intent with BASF and Nornickel to set up a battery recycling cluster to serve the electric vehicle market. In concrete terms, BASF is setting up a recycling facility in Harjavalta, Finland.