In Austria, the Graz University of Technology has opened a new facility for the development of solid-state batteries with their industrial partner AVL. Called the Christian Doppler Laboratory, the facility deals in depth with the reduction of interfacial resistances within the solid-state battery.

Solid-state batteries promise much higher energy and power densities than current batteries with liquid electrolyte. According to Daniel Rettenwander, head of the new laboratory, the technology is not yet mature and “Solid-state batteries would be a giant step towards area-wide e-mobility”. A major challenge is high resistances form at the interfaces that prevent rapid ion transport between the electrodes and thus lead to a significant loss of performance.

“In most cases, the culprits are the interfaces between the solid-state electrolyte and the electrode material and between particles of the electrolyte itself,” says Rettenwander, who and his team are focusing on several approaches to solving the problem: “The current density distribution at the interfaces can be homogenised, for example, by introducing intermediate layers with finely tuned lithium transport properties.” The researchers also want to test alternative charging methods and use different pulse charging methods instead of direct current to achieve homogeneous lithium deposition.

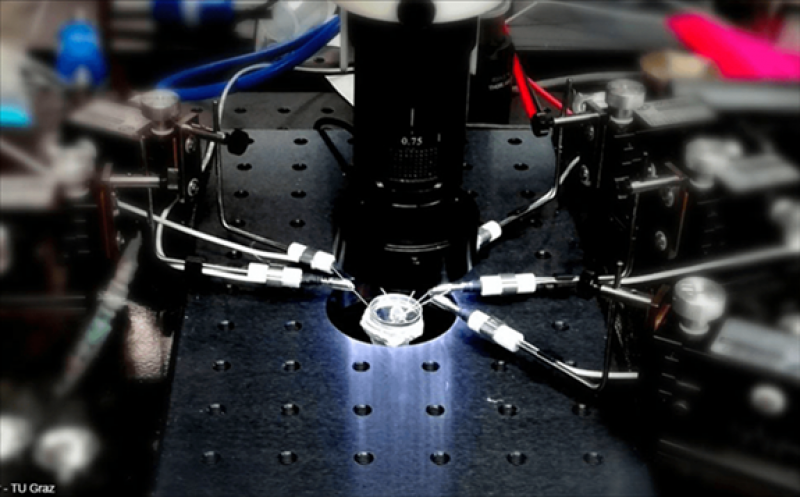

Research in this area is centralised at the TU Graz in the new Christian Doppler Laboratory, which is now the twelfth CD laboratory at the Austrian university. What these laboratories have in common is that they are based on research cooperations with commercial enterprises and are financed both publicly and by the participating companies. Drive and testing specialist AVL is on board the CD Laboratory for solid-state batteries. AVL is also on board at the Center for Battery Safety at Graz University of Technology, presented a month ago. The focus here, for example, is on two topics: the defined ageing of batteries to analyse their long-term behaviour and the behaviour of charged batteries under mechanical stress in general and during accidents in particular. Accordingly, the initiators of the centre say that the heart of this facility are the climate chambers for targeted battery ageing and the mechanical test facilities, including a crash facility for charged batteries.

At the new CD Laboratory just opened to further work on solid-state batteries, AVL emphasises the importance of the new CD Laboratory for its own business: “As a developer of innovative drive batteries, the research findings are extremely valuable for the development of future battery modules based on solid-state battery technology,” says Volker Hennige, Head of the Battery Department at AVL. The joint research is scheduled to last seven years. The budget of the CD Laboratory with its seven employees totals around two million euros. The Federal Ministry for Digitalisation and Business Location (BMDW) is the most important public funding agency.

Laboratory manager Rettenwander explains that the development of solid-state batteries is already relatively far advanced in contrast to lithium-air batteries or similar experimental battery technologies. “It will still take some time before this type of battery is ready for high-energy applications, such as in electric vehicles, but it is foreseeable even here in Styria as solid-state batteries are already being found in isolated cases as small batteries for electronic components.” The company is familiar with the specific problem areas, is working concertedly on sustainable solutions and sees itself as an important launchpad for the next generation of energy storage systems.

This article is reproduced at www.electrive.com