Photonic nanostructures found on the wings of some butterflies have inspired researchers in Australia to create a new and highly accurate sensor for measuring hydrogen gas. The device operates at room temperature and was made by a team led by Yilas Sabri and Ahmad Kandjani at RMIT University in Melbourne. The sensor could play a role in the safe industrial storage of hydrogen fuel and the research could also lead to the development of new techniques for non-invasive medical diagnoses.

As a promising source of renewable energy, increasing amounts of hydrogen gas are now being stored at large facilities around the world. Because of the extreme flammability of this gas, there is a need for highly accurate sensors that can detect even the smallest traces of hydrogen that has leaked into the air. Today’s commercially available sensors measure changes in electrical resistance in metal-oxide layers as they interact with hydrogen. However, these devices require temperatures of over 150 °C to operate and are also sensitive to other types of gas – limiting their potential for industrial applications.

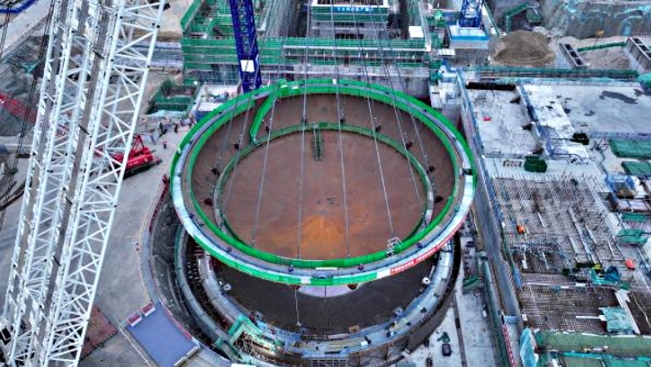

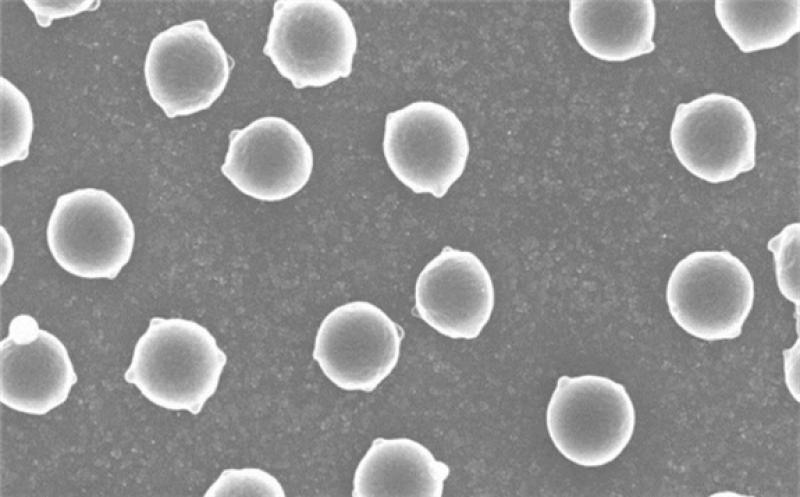

Sabri and Kandjani’s team took a more sophisticated approach in their study; where instead of heat, hydrogen detection in their sensors is assisted by light. Their design employs photonic crystals: optical nanostructures that can be manufactured, but also appear in nature. In this case, the team was inspired by the wings of some butterflies – which have orderly patterns of tiny bumps that make the wings extremely good at absorbing light. To mimic this structure, the researchers fabricated a lattice of hollow titanium dioxide nanospheres, which they deposited onto an electronic chip. They then coated the device with a titanium palladium composite to enhance its sensitivity.

Explosion alarm

When activated by light, the surface of this sensor reacts hydrogen gas with oxygen to create water. The presence of water changes the sensor’s electrical resistance, providing a precise measure of the amount of hydrogen in the air. Operating at room temperature, the sensor can measure concentrations in the 10-40,000 parts-per-million range. It can therefore sound the alarm when the concentration of the gas is high enough to be an explosion risk. The device can discriminate between hydrogen and other gases with a selectivity that exceeds 93%.

The sensor was made using established fabrication processes so the team is confident that production could easily be scaled up for widespread using – including in hydrogen fuel cells. Furthermore, the ability of the sensors to detect low levels of hydrogen make them suitable for medical applications. By detecting the gas produced by gastrointestinal disorders in a patients’ breath, clinicians could carry out non-invasive diagnoses and monitoring procedures far more easily.