In October, when the International Energy Agency pronounced solar energy the “cheapest electricity in history,” their claim rested on largely inefficient panel technologies in the 15-25 percent range. Imagine, say perovskite PV advocates, what new standards solar power could set with efficiencies of 30 percent or more.

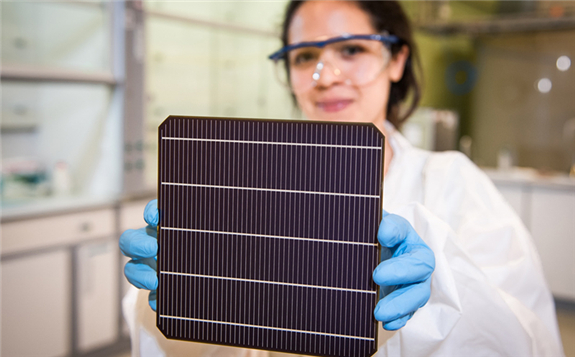

Photo: Oxford PV An Oxford PV commercial sized perovskite-silicon tandem cell.

Photo: Oxford PV An Oxford PV commercial sized perovskite-silicon tandem cell.

As of December, photovoltaic panel efficiency ratings north of 30 percent no longer seemed quite so theoretical either.

December was the month the U.S. National Renewable Energy Laboratory certified U.K. startup Oxford PV’s new record: A single solar cell coated with the mineral perovskite, NREL confirmed, can now convert 29.52 percent of incident solar energy into electricity. According to NREL’s own benchmarking, conventional silicon cells appear to have maxed out at 27.6 percent.

Oxford PV, a ten-year-old spinoff from the University of Oxford, in England, say they expect to cross over into the 30s soon, too.

At its current pace, the company says it expects to be manufacturing cells with 33 percent efficiency within four years. One competitor in the perovskite-silicon PV race, the German research institute Helmholtz-Zentrum Berlin, has already achieved 29.15 percent efficiency with their perovskite cell and expects to be able to push its rating up to 32.4 percent.

“We hope [this technology] will change the face of photovoltaics and accelerate the adoption of solar to address climate change,” Chris Case, Oxford PV’s chief technology officer, says of his company’s tandem perovskite-silicon cells.

The tandem approach—coating an ordinary silicon wafer with a thin-film layer of perovskite material—enables Oxford PV to capture more available solar radiation. The perovskite layer absorbs shorter wavelengths, while the silicon layer absorbs longer wavelengths. To improve efficiency, the company expects to refine the cells’ coatings and antireflection layers and remove defects and impurities, Case says.

Companies and universities worldwide are looking to perovskites as a potential future replacement for silicon, in the hopes of making renewable energy more affordable and accessible.

Early prototypes of perovskite solar cells were unstable and degraded quickly. But over the past decade, researchers have steadily improved the stability and durability of perovskite materials for both indoor and outdoor applications.

Oxford PV expects to start selling its perovskite-silicon cells to the public in early 2022, says CEO Frank Averdung. That would make it the first company to bring such a product to the global solar market.

The startup is expanding its pilot plant in Germany into a 100-megawatt-capacity solar cell factory. Oxford PV began producing small volumes of cells there in 2017. The company has field-tested the technology for more than a year, Case says.

So far, he adds, data suggest the cells perform about the same as commercial silicon panels. “We see no degradation that’s any different than reference commercial panels that we’re comparing to,” Case says.

He says it typically takes a couple of years for efficiency achievements in the lab to appear in factory-produced cells. Thus the first devices off Oxford PV’s manufacturing line will have an efficiency of 26 percent—higher than any other commercially available solar cell, Averdung says. The company expects residential rooftop solar projects using its technology will generate 20 percent more power using the same number of cells as existing installations.

Some solar researchers remain skeptical of perovskites, pointing to the material’s potential to degrade when exposed to moisture, harsh temperatures, salt spray, oxygen, and other elements. Case says Oxford PV’s cells have passed a battery of accelerated stress tests, both internally and by third parties.

“They will definitely be expected to last as long or longer than any of the best silicon modules that are out there,” he says of the cells.

This article is reproduced at spectrum.ieee.org