Dutch startup SolarDuck has developed an innovative offshore floating solar solution that is purportedly ideal for offshore conditions.

Image: SolarDuck

Image: SolarDuck

“We are targeting megacities and large companies in the Mediterranean, the Caribbean, South East Asia, and in general markets with high solar radiation in the global Sun Belt,” CEO Koen Burgers said.

The floating structure is designed to handle coastal sea conditions and hurricane-force winds. It is also optimized for offshore sites in estuaries, natural harbors, as well as near-shore sites.

“We have developed a near-shore concept, which can cope with waves that can be more than 3 meters high and hurricane winds,” Burgers said.

The company is now testing the system in the North Sea, where waves can be much higher.

“This kind of project, however, requires a stronger design and more expensive electrical cables and has larger efficiency losses,” Burgers said.

Offshore lessons

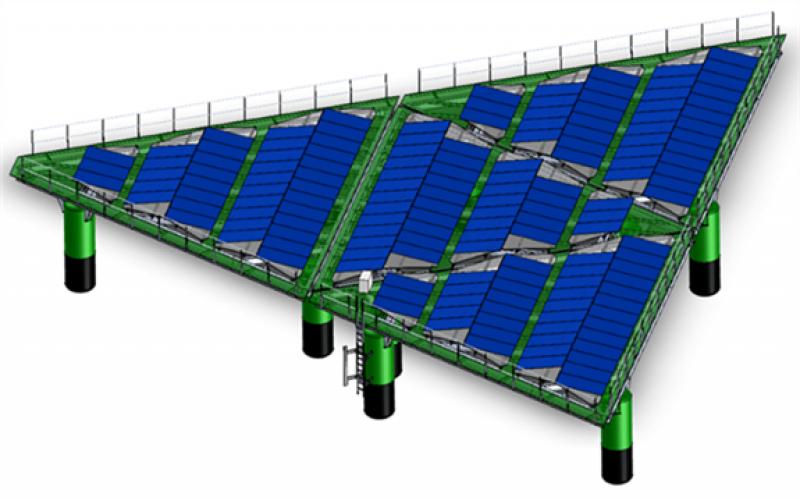

The company's basic floating platforms are triangular structures measuring 16 x 16 x 16 meters. They resemble offshore floating wind platforms or floating oil platforms. They can be flexibly connected together to form large plants.

“The idea is based on our offshore heritage,” Burgers said. “Our company is a spinoff from the research department of the Damen Shipyards Group in the Netherlands, a company which uses the best of industry practice to design a reliable solution which is able to cope with the harsh maritime environment.”

Each platform is placed on floating pillars, Burgers noted.

“It is more or less a semi-sub structure that is used in offshore floating wind projects,” he explained. “What we did was connecting these platforms in a smart way and by elevating the platforms you get much less wave resistance” he explained. Despite the similarity with offshore wind platforms, the floating structure designed by the Dutch company is claimed to be much lighter.

The platforms allow the company to place PV modules more than 3 meters above the water surface.

“Our structure elevates all PV and electrical parts above the waves,” said SolarDuck CTO Don Hoogendoorn. “This avoids that waves will impact the panels, which causes micro-cracks.”

The distance from the water surface also ensures that the modules and other components stay dry. And the company claims that the large size of the platforms is favorable from a power output perspective, as the platforms move around less, which ensures more stable power output.

This particular configuration enables the use of conventional PV modules without the need for specifically designed products. “As far as possible, we try to use proven commercial products with the highest durability, because in this way you can utilize the latest developments in the solar industry,” Hoogendoorn added.

Chinese manufacturer Astronergy supplied the modules for the first pilot projects. Dutch materials specialist DSM is providing its high-performance polyolefin Endurance backsheets, which have been fitted to the modules.

“We are currently measuring the performance of both glass-glass and glass-backsheet solutions,” Hoogendoorn said.

The first pilot projects will be assembled at Damen Shipyards, with Norsk Hydro Extrusion providing the aluminum extrusions.

“We want to use components that allow us to scale our technology fast,” Hoogendoorn added. “This is why we are working together with these leading parties.”

The triangle

The company claims the triangular shape of the floating structure can handle waves and dynamic loads.

“We designed it with the offshore safety standard in mind,” Hoogendoorn said. “Due to triangle shape and large size of the platform it is relatively stable and this enables safe operation and maintenance services at sea.”

When platforms are too small, they move with the waves, which makes maintenance and cleaning at sea difficult. Furthermore, the triangular shape is purportedly the most beneficial ratio between strength versus mass compared to other shapes – especially due to waves, which cause the highest torsional loads on PV plants.

Hoogendoorn also said that, due to its triangular shape of the platforms, offshore PV plants can be adapted to specific customer requirements.

“We also designed a shape that looks like a diamond,” he stated. “We are flexible in adapting the design and can eventually create a lot of plant shapes.”

The floating structure is not able to follow the sun in a tracking configuration as it will always maintain the same position. “Key in designing a reliable offshore solution is that it needs to be robust and simple,” Hoogendoorn added. “Therefore we designed it with a fixed east-west orientation”

The company claims the technology is also particularly competitive from a capex and opex perspective.

“The structures may be a bit costlier than other offshore technologies, but are designed with a lower [levelized cost of electricity] in mind, since the technology is more reliable and maintenance-friendly,” Hoogendoorn said.

Each triangle can be fully standardized to the same size, in order to bring costs down. Eventually, local robotized production will enable mass production. The company is currently aiming at building standard projects with a capacity of 10 MW, but projects of this size may eventually be grouped and form floating complexes of up to 500 MW.

“With these triangles, we set the standard to build utility-scale offshore floating solar plants,” Hoogendoorn said.

Pilot project

SolarDuck has secured €350.000 from the Dutch province of Gelderland to implement its first pilot project, in partnership with Dutch hydrogen producer Voyex.

“The first full-scale demonstrator will be launched in April on on-shore water and a second pilot project will be built in the Belgian North Sea early next year,” Burgers explained. “This fits very well with our long-term ambition to use the electricity and use it to increase value.”

The company will deploy its first real offshore PV plant on the Waal, a major waterway connecting the port of Rotterdam to Germany. SolarDuck will supply four linked platforms fitted with 39 solar panels each. The project will have a total installed capacity of 65 kW and will be connected to a 10 kW electrolyzer operated by Voyex.

The project will be built at a cost of €1 million. The two companies plan to disclose more details after the official launch. Both of them have the long-term ambition to produce hydrogen using floating solar islands at sea, in order to supply the shipping sector and other heavy-duty applications.

“Since its establishment in April 2019, SolarDuck has been developing rapidly,” Burgers concluded. “To further accelerate this development, the company is currently in preparation of a funding round.”

This article is reproduced at www.pv-magazine.com