Converting sunlight into hydrogen is a seemingly ideal way to address the world’s energy challenges. The process doesn’t directly involve fossil fuels or create any greenhouse gas emissions. The resulting hydrogen can power fuel-cell systems in vehicles, ships, and trains; it can feed into the electrical grid or be used to make chemicals and steel. For now, though, that clean energy vision mainly exists in the lab.

Recently, Japanese researchers said they’ve made an important step toward making vast amounts of hydrogen using solar energy. The team from Shinshu University in Nagano studies light-absorbing materials to split the hydrogen and oxygen molecules in water. Now they’ve developed a two-step method that is dramatically more efficient at generating hydrogen from a photocatalytic reaction.

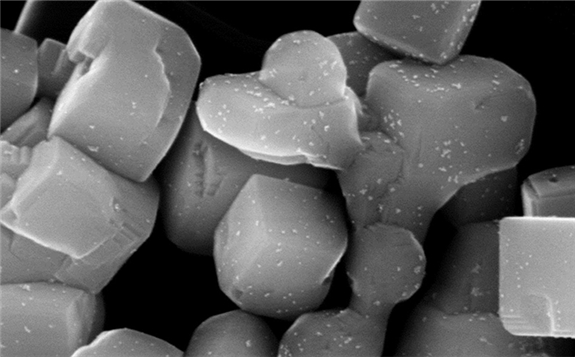

The researchers began with barium tantalum oxynitride (BaTaO2N), a semiconductor material that can absorb light at up to 650 nanometers (a visible wavelength at the orange end of red). The powdery substance serves as the photocatalyst, harnessing solar energy needed to drive the reaction. They also used an aqueous methanol solution instead of water, which allowed them to focus only on the hydrogen component and reduce the complexity of the reaction.

By itself, BaTaO2N can hardly “evolve” hydrogen gas from the solution. So, using their new method, the Shinshu team “loaded” the powder granules with a platinum-based co-catalyst to improve the chemical activity.

As a result, the materials evolved hydrogen much more efficiently—about 100 times more efficiently—than BaTaO2N that’s been loaded with platinum using conventional methods, according to their paper in the journal Nature Communications.

Takashi Hisatomi, a co-author of the study, said the results are a “remarkable finding” in this research field. Hisatomi is a professor with Shinshu’s Research Initiative for Supra-Materials in Nagano, Japan, and he has studied BaTaO2N for nearly a decade. “This is personally very exciting for me,” he said of the 100-fold improvement.

Solar energy experts have called efforts to make hydrogen more easily or efficiently a “Holy Grail quest.” When used in fuel-cell-powered vehicles or buildings, the odorless gas doesn’t produce emissions or air pollution—just a little heat and water. However, nearly all hydrogen today is made using an industrial process that involves natural gas, which ultimately pumps more emissions into the atmosphere. A handful of facilities can make “green” hydrogen using renewable electricity to split water molecules, but the process itself is energy-intensive. If scientists can directly make hydrogen from the sun’s energy, they could bypass this expensive step.

In Belgium, a team at Katholieke Universiteit Leuven is developing solar panels that collect moisture in the air, then use chemical and biological components to split water directly on the surface. The researchers envision putting these panels on top of houses, allowing people to heat their homes with hydrogen gas made on site. Separately, Israeli and Italian scientists are advancing methods to extract as much hydrogen as possible from solar-to-chemical energy conversion. The international group has developed rod-shaped nanoparticles, tipped with platinum spheres, that prevent hydrogen and oxygen from recombining after the molecules are separated.

At Shinshu, the researchers sought to improve the efficiency of the BaTaO2N photocatalyst by depositing the platinum-based co-catalyst. But the conventional methods for doing so weren’t initially effective, Hisatomi said.

For instance, in the impregnation-reduction process, a surface is filled with a solution containing metal precursors and then subjected to elevated temperatures, which evaporates the solvent and leaves behind the metal catalysts. When the Shinshu team applied fine particles of platinum to the BaTaO2N granules, the particles tended to aggregate, restricting the electronic interaction between the materials. Another method, called photodeposition, resulted in weak contact between the BaTaO2N and co-catalyst, in turn weakening the interaction.

So the researchers combined these two methods. First, they deposited only a small amount of the co-catalyst using the impregntation-reduction process, and that prevented the particles from aggregating. Then they applied a second layer using photodeposition; this time, the fine particles grew on the widely dispersed “seeds” planted in the first step. Zheng Wang and Ying Luo conducted the investigation, under the supervision of Kazunari Domen and Katsuya Teshima, respectively.

Although the study involved an aqueous methanol solution, not water, the team confirmed that the newly developed platinum-loaded BaTaO2N can split the hydrogen and oxygen molecules in water more efficiently than earlier BaTaO2N versions, when combined with another photocatalyst that drives the oxygen evolution process.

Hisatomi said the team is considering printing the powdery photocatalyst on a panel-type reactor. He and his colleagues have already built such a device using another material, aluminum-doped strontium titanate (SrTiO3), which has the same crystal structure as BaTaO2N but absorbs lights at different wavelengths. The 1-square-meter panel reactor is filled with a 1-millimeter-deep layer of water. When exposed to sunlight, the chemical reaction rapidly releases gas bubbles. A related research effort aims to develop membranes that can keep the hydrogen and oxygen bubbles separated.

Still, despite the 100-fold efficiency jump, BaTaO2N isn’t quite ready for prime-time hydrogen production.

“We still need a similar jump in improvement of the efficiency to make this technology practically useful,” Hisatomi said. As researchers continue improving the photocatalyst, they’ll also begin applying the two-step approach to other types of materials. “We don’t know which material will become the best in the end,” he added.