The Volkswagen Group Components plant in Braunschweig is significantly expanding its production of battery systems for the latest electric vehicle generation. Following the first expansion stage with a maximum capacity of 250,000 battery systems, the second expansion stage has started up with the same capacity.

Thus, once the site is fully ramped up it will now be able to fit up to 500,000 batteries a year for models based on the modular electric drive matrix (MEB)—in this case for the fully electric Volkswagen ID.3 and ID.4, as well as the ŠKODA ENYAQ iV.

In addition to that, the plant will produce up to 100,000 battery systems for the e-up!, SEAT Mii electric, ŠKODA Citigoe iV and as well as for hybrid vehicles such as the Volkswagen Golf GTE. In total, the site can bring more than 600,000 battery systems into the vehicles each year.

The next ramp-up is coming soon: the plant has received approval for expanding PHEV production capacities. While more than 50,000 hybrid battery systems a year are leaving the plant today, as of 2023, this will be up to 300,000 battery systems.

In addition to the battery systems, Braunschweig also produces steering systems, brake discs, suspension struts, wheel bearing housings, wheel drives and subframes, and also front and rear axles, for example.

Series production of MEB batteries takes place using the state-of-the-art, largely fully automated production technology in a new manufacturing hall spread across more than 40,000 m2; more than €300 million have been invested in the new building.

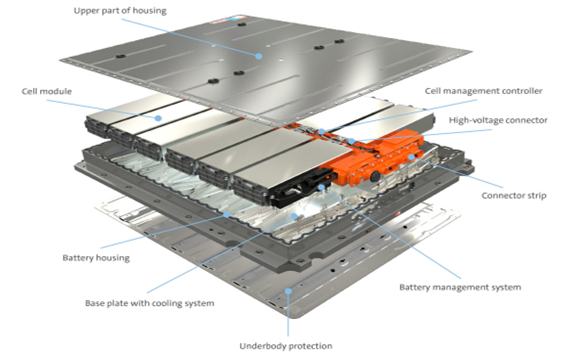

Production of the battery housing employs the latest welding, adhesive and sealing techniques. The housing units are then assembled together with the cell modules and a control unit to form the actual battery systems. Several in-line, air-tightness and end-of-line test beds guarantee uniformly high quality.

The development of the battery system, including its hardware and software, also took place at the Braunschweig site.