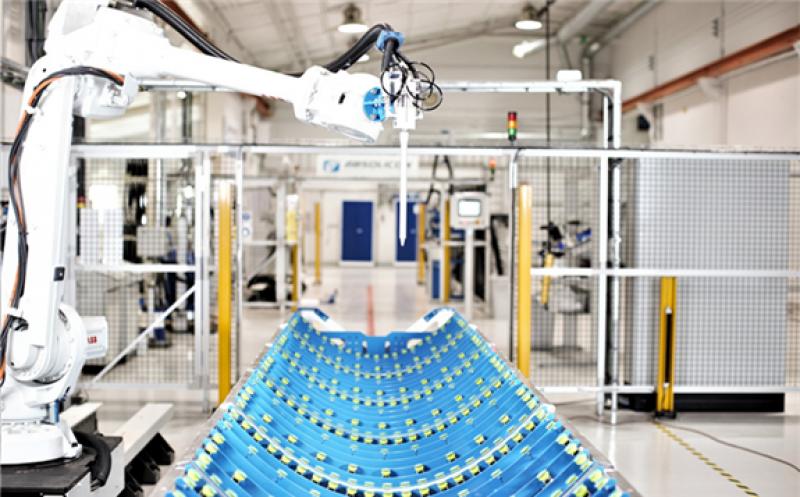

To enable the transformation to a sustainable society and preserve resources, production of solar collector panels must be precise, highly efficient, and cost effective. To achieve this, Absolicon and ABB have developed a complete solution for the mass production of concentrated solar collectors, in Absolicon’s factory in Härnösand, Sweden.

"Developing an automated production process enables our global business case by radically reducing the price of our solar collectors, while manufacturing them consistently to a very high quality. The productivity offered by ABB’s robots means we can make solar energy compete on price with conventional industrial heating for the first time," said Joakim Byström, CEO of Absolicon. “Our new automated production line can produce a complete solar collector every six minutes, so while competitors rely on a manually intensive manufacturing process, we can now do it with five people, two robots, and a fraction of the components.”

Absolicon has been developing sustainable solar technology for 20 years and produces parabolic solar collectors that are the most efficient in their class, generating heat and steam up to 160° for industrial companies and district heating networks.

“We’re pleased that ABB’s robotics solutions are accelerating the productivity, quality, and cost efficiency of Absolicon’s production line to enable them to bring a renewable energy product to market at a competitive price,” said Sami Atiya, President of ABB’s Robotics & Discrete Automation Business Area. “In helping Absolicon to accelerate their production from three units a day to one every six minutes, our robotics solutions are playing a key role in accelerating the global adoption of sustainable technology, ensuring Absolicon’s production partners are able to consistently produce solar collector panels globally.”

“Our vision is to enable a cost-effective mass-production of solar collectors across the world, to produce heat directly from sunlight,” added Byström. “Our work with ABB to create this automated production process is a key enabler to realise our vision, while ABB's global service organisation will be a very valuable resource for our new customers as we roll-out our new automated production line globally.”

The next phase of the project involves supplying complete robotic production lines to manufacturing partners across the globe and ABB and Absolicon have agreed they will collaborate on the development, sales, and marketing of the robotic production line worldwide.

The first installation has already been delivered to a partner in China, and framework agreements for the acquisition of robotic production lines have been signed with businesses in a dozen countries, with ABB supplying the robots for all new installations.