Primobius GmbH is a 50:50 joint venture company owned by Neometals Ltd., Australia, and SMS group to commercialize an environmentally friendly recycling solution for end-of-life and scrap lithium-ion battery (LiB) cells. Primobius has now signed a memorandum of understanding (MoU) with Stelco Inc., Canada, a wholly-owned subsidiary of Stelco Holdings Inc., a steel manufacturing company headquartered in Hamilton, Ontario.

Stelco is pursuing initiatives with major automobile producers to recycle end-of-life automobiles to recover valuable materials for re-use or re-sale. Recycling the lithium-ion batteries contained in electric vehicle automobiles is a major aspect within this value chain, which will become even more important in the future.

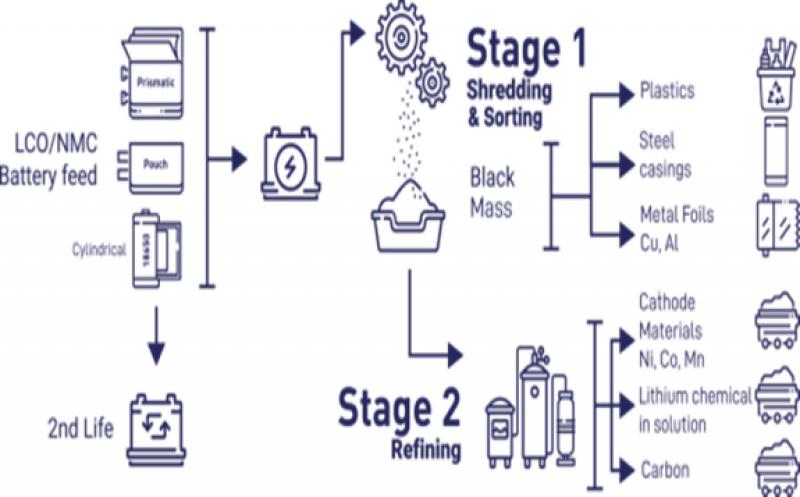

Primobius offers a sustainable process for the recovery of valuable constituents from cell production scrap and end-of-life LiBs. The processing flowsheet targets the recovery of battery materials from LiBs that might otherwise be disposed of in land fill or processed in energy-intensive pyrometallurgical recovery circuits.

Specifically, the recycling process targets the recovery of valuable materials from consumer electronic batteries (devices with lithium cobalt oxide (LCO) cathodes), and nickel‐rich electric vehicle and stationary storage battery chemistries (lithium‐nickel-manganese‐cobalt (NMC) cathodes).

The MoU provides a framework towards establishing a 50:50 incorporated lithium-ion battery (LiB) recycling joint venture (JV) in North America. Under the JV, Primobius would supply a dedicated recycling facility adjacent to Stelco’s proposed vehicle recycling operation, for operation by the JV partners with equal contribution of capital costs and sharing of financial returns.

By entering into the MoU, Primobius and Stelco intend to share information, conduct due diligence, collaborate and build a business case for a long-term commercial relationship between the parties. The MoU contemplates the potential formation of a 50:50 incorporated JV to process battery cells arising primarily from scrap and end-of-life vehicles in North America.

Primobius will supply and construct a recycling plant initially with a nominal 20,000 tons-per-year cell processing capacity for the JV while Stelco will arrange sufficient supply of battery cell feed to the plant. The JV and Stelco would actively plan for an expanded capacity operation to capture future increased quantities of cells if they become available.

The facility will be modeled on Primobius’ proprietary refining process following the successful completion of the demonstration trials at its showcase facility. Primobius’ demonstration plant is currently being assembled in a dedicated warehouse at the SMS group manufacturing center in Hilchenbach, Germany.

This MoU with Stelco is significant and represents not only another recycling partnership validation for Primobius, but the first targeting end-of-life electric vehicle batteries. It also represents the first commercial relationship in North America, which is home to five battery megafactories in production.

In this circular economy, Primobius represents an energy-efficient process and flexible system that meets the needs of various actors and helps achieve sustainability goals as it produces high purity chemicals for re-use in the next generation of LiBs.