NAWA Technologies has begun manufacturing its Vertically Aligned Carbon Nanotube (VACNT) material at its Aix-en-Provence facility in southern France. NAWA is showing that, for the first time, VACNT can be grown simultaneously on both sides of a substrate in a process that is fully scaleable.

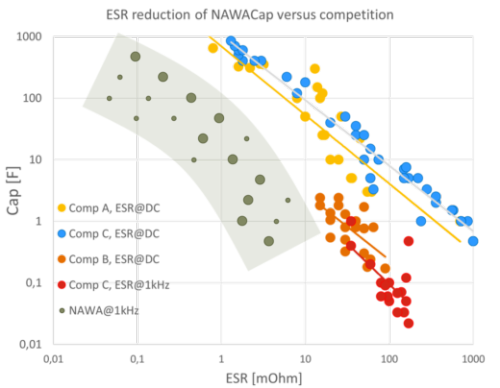

NAWA’s key applications for VACNT include the Ultra Fast Carbon Electrode for high-performance batteries; next-gen ultracapacitors, NAWACap, which offer up to five times more power capability than conventional technology; and the NAWAStitch advanced reinforced composite.

NAWA grows VACNT simultaneously and homogeneously on both sides of a substrate at atmospheric pressure using a Chemical Vapor Deposition (APCVD) process, in a roll-to-roll manner.

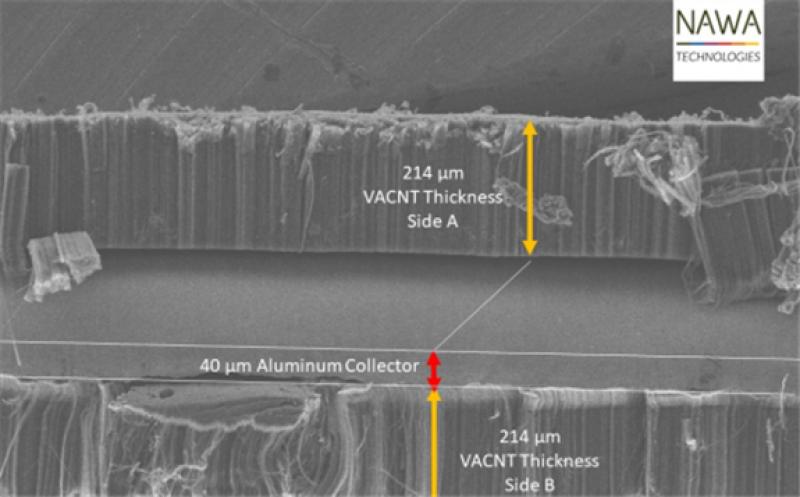

The process has demonstrated the ability to grow up to more than 200 micrometer long VACNT double-sided simultaneously on a 30 cm wide aluminum foil, and to selectively grow VACNT on the foil—essential for advanced electrode designs and production efficiency.

NAWA says that this development process is just the start of a scale-up in terms of foil width and roll-to-roll productivity.

A flexible and modular manufacturing system, its specific design makes it very compact compared to conventional coating equipment resulting in a footprint in a factory environment that is minimized, while the highly-efficient process means that the production cost of NAWA’s VACNT material can achieve parity with that of a current electrode at future mass production levels, according to the company.