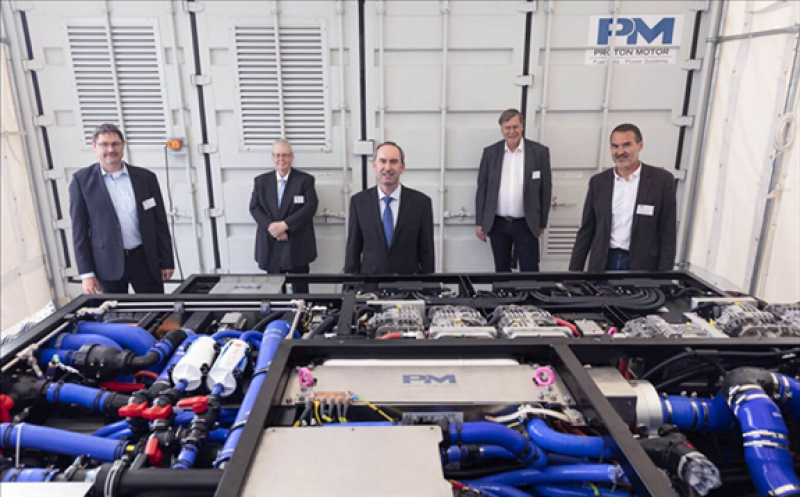

Proton Motor welcomed the Bavarian Deputy Prime Minister and Minister of Economic Affairs at its operating site in Puchheim on Wednesday (July 7) to showcase its a hydrogen fuel cell drive system for rail.

The fuel cell drive system is set to be implemented into a milling train in Austria with delivery expected for July 2021.

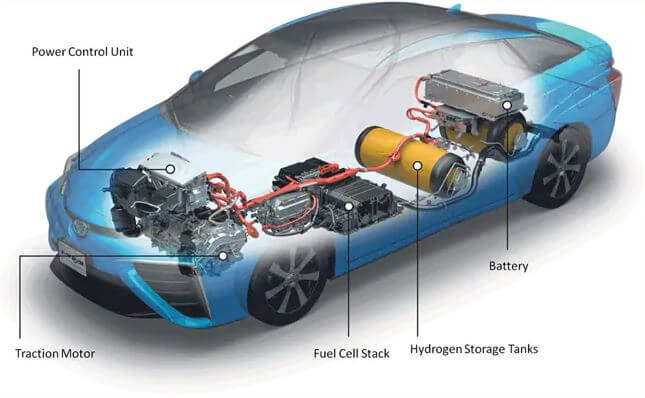

The tailor-made hydrogen fuel cell system has an installed capacity of 214kW, consisting of two fully redundant systems of 107kW each.

The emission-free fuel cell system from Proton Motor is to be integrated into the world’s first special track construction machine with a purely electric drive, the company has said.

In contrast to previous model series with diesel engines, the high-performance milling machine also completely dispenses with hydraulics in the working units.

The hydrogen-powered rail thus provides an answer to the increasingly strict authorities regulations regarding environmental factors exhaust and noise pollution.

Especially in subway tunnels, the new machine type based on future-oriented renewable energy supply represents an improvement from an ecological point of view in favour of the desired carbon neutrality.

In addition, the health risk of the operating crew in the track benefits from the zero- emission milling concept, in which the dust pollution is eliminated.

Hubert Aiwanger, Deputy Prime Minister of Bavaria, visited the Puchheim site during the technical review of the sustainable multistack system.

“I am convinced that hydrogen and fuel cell technologies in particular will make an important contribution to achieve the sector-specific climate protection targets.

“Especially in heavy-duty traffic with high vehicle weights and necessary ranges, the fuel cell drive has great potential to rapidly advance the decarbonisation of the transport sector.

“Proton Motor Fuel Cell acts as an important player in our Bavarian hydrogen economy thanks to many years of experience in the field of fuel cell development and production.

“With its innovative Proton Motor technology, the company impressively demonstrates that climate-friendly drive solutions can also be implemented in rail transport.”