Holtec is preparing to increase production of its HI-STAR casks, following the receipt of regulatory approvals and new orders in Europe. The first HI-STAR 150 was loaded at the Cofrentes nuclear power plant in Spain and placed into the storage facility on 23 June. This is Holtec's first dual-purpose metal cask loaded in Europe.

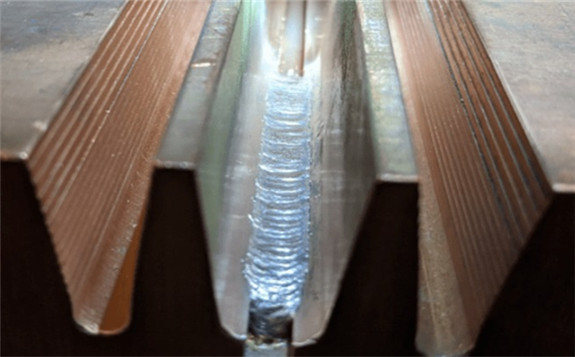

Full Scale Mockup of Copper Weld Joint for the HI-STAR 80 with Single Pass Hybrid Arc Laser (Image: Holtec)

Holtec has produced more than 25 HI-STAR casks in the last five years - five HI-STAR 150 casks for Spain; 14 HI-STAR 100 casks for South Africa; three HI-STAR 190 casks for Ukraine; and seven HI-STAR 100MB casks for China. Holtec currently has over 10 HI-STAR casks in production, including for clients in Sweden and Switzerland, and these are in addition to a new HI-STAR 150 order from Spain.

"Although our manufacturing facilities have been critically impacted by the pandemic and we are still dealing with its aftereffects, we remain absolutely committed to meeting the needs of our clients," Richard Springman, Holtec's senior vice president of international projects, said. "As an innovation company, we have naturally turned to technology and innovation to support fulfilling our delivery backlog with improved productivity and quality," he added.

Spanish approval

In 2017, Spanish decommissioning firm Enresa contracted Holtec for the design, engineering, licensing and manufacture of five HI-STAR 150 casks for the Cofrentes plant. In April this year, the Spanish Nuclear Safety Council granted a favourable evaluation of the design for storage and in May it received a storage licence from Spain’s Ministry of Ecological Transition and the Demographic Challenge. On 2 July, Enresa awarded Holtec a contract to produce an additional 10 HI-STAR 150 casks that will be produced in the USA.

The HI-STAR 150 cask is licensed for storage of up to 52 boiling water reactor (BWR) used fuel assemblies, including damaged ones. Extension of the licence to increase the number of fuel assemblies with Crud-Induced Localised Corrosion is on-going.

Other designs

Holtec’s HI-STAR 180L, designed for up to 69 BWR used fuel assemblies, received US Nuclear Regulatory Commission (NRC) approval for transport in April.

In Belgium, the Federal Agency for Nuclear Control (FANC) approved the HI-STAR 180D for transport in June.

Holtec says it is in advanced stages of production of the initial batch of two HI-STAR 180D casks, with additional orders pending.

The HI-STAR 180D casks are for the Doel nuclear power plant in northern Belgium, with the first cask expected to be loaded next year after authorisation from Bel-V, the subsidiary of FANC with regulatory oversight for storage.

The HI-STAR 180D is the "sister cask" to the HI-STAR 180, which has been under review by ENSI, the Swiss Federal Nuclear Safety Inspectorate, for storage and transportation since 2009. First approved for transportation by the NRC in 2009, this design is the first cask licensed with Holtec’s proprietary Metamic-HT fuel basket.

The HI-STAR 100MB is designed based on the HI-STAR 100 and HI-STAR 190 transport casks for retrieval of large-diameter canisters from nuclear power plants with onsite storage facilities. It also includes the option to transport unpackaged fuel without a canister.

HI-STAR 100MB is now under the final stage of licensing approval for transportation by China's National Nuclear Safety Administration based on the NRC’s transport licence.

Holtec is also preparing to start manufacturing a series of HI-STAR ATB1T (or HI-STAR 330) casks licensed by the NRC in June as a Type B transport cask. This rectangular cask is developed for high activity waste generated during reactor dismantling. The first production run is for a client in Sweden, while the second is for Holtec's US decommissioning fleet, with first deployment at the Oyster Creek nuclear power plant.