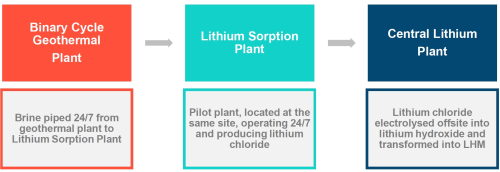

Vulcan Energy Resources’ chemical engineering team has successfully produced its first battery-quality lithium hydroxide monohydrate (LHM) from piloting operations. The LHM was produced from Vulcan’s sorption pilot plant, located at a geothermal renewable energy plant in the Upper Rhine Valley in Germany, with downstream electrolysis processing offsite, as per Vulcan’s planned commercial Zero Carbon Lithium Project.

The sample exceeds traditional battery-grade LHM product including best on the market battery-grade specifications required from offtake customers, at >56.5% LiOH.H2O and very low impurities.

The lithium chloride extracted by the sorbent in the pilot plant was recovered with water and sent offsite, where it was purified and concentrated by a third-party provider to prepare the lithium chloride for electrolysis to produce lithium hydroxide solution. The solution was then crystalized to produce battery grade lithium hydroxide monohydrate (LHM).

Further production of battery quality material will continue to ramp up to supply Vulcan’s offtake partners with samples. Vulcan is targeting Phase 1 commercial production for CY2024.

Data generated during the production of the sample will be used for Vulcan’s ongoing Definitive Feasibility Study currently being carried out by Hatch and Vulcan’s engineering teams.

Vulcan’s pilot has been operating successfully since April 2021, using brine from a geothermal plant, and will be progressively scaled up in size during the coming year.

Vulcan is aiming to become the world’s first lithium producer with net zero greenhouse gas emissions. Its Zero Carbon Lithium Project intends to produce a battery-quality lithium hydroxide chemical product from its combined geothermal energy and lithium resource, which is Europe’s largest lithium resource, in Germany.