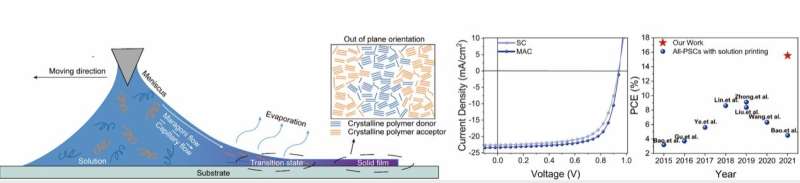

Different from the conventional fabrication of solar cell by spin coating (SC) approach, Prof. Wang Jingxia's team from the Technical Institute of Physics and Chemistry of the Chinese Academy of Sciences (CAS) and Prof. Huo Lijun from Beihang University have developed a solution printing strategy for meniscus-assisted-coating (MAC).

The strategy was proposed to prepare high-quality blend films with the optimized morphology of the active layer. The efficiency of as-prepared all-PSCs is 15.53 percent from MAC, which was higher than prepared by the SC method (14.58 percent), owing to the more ordered molecular packing and better nanofiber interpenetrating network structure for active layer prepared by MAC.

Relevant results have been published in Advanced Materials.

The researchers found that solution shear rate greatly affects the three-phase contact line geometric shape, material crystallization kinetics and phase separation size, and the crystallinity of active layer material.

Meanwhile, they have extended the MAC method to the preparation of 1×1 cm2 devices with power conversion efficiency (PCE) over 12 percent. Various active layer films with PCE>15 percent are also prepared.

"This work not only provides a simple and efficient solution printing method for the preparation of all-PSCs, but also gives constructive theoretical guidance at different shear rates," said Prof. Wang.