Perovskite solar cells are an emerging technology that could significantly improve the efficiency and stability of photovoltaic cells. However, challenges in manufacturing the material have prevented businesses from bringing perovskite to market.

Breakthroughs could make perovskite practical, but manufacturers need to make them work at scale first. This may be challenging for companies to achieve, but progress is being made that may pave the way for future developments.

What is perovskite?

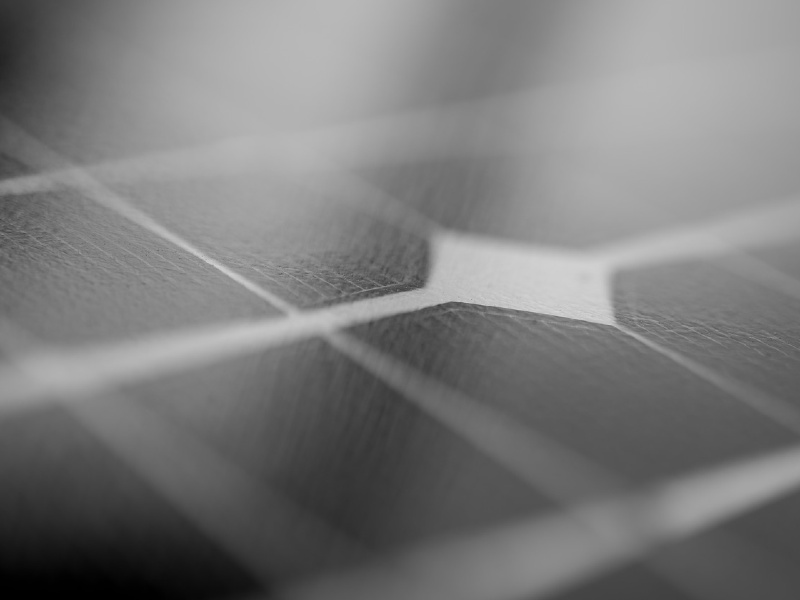

Perovskite is a family of materials with a specific crystalline structure that matches calcium titanium oxide, the first-discovered perovskite crystal. This crystalline structure gives perovskite crystals unique physical, optical and electrical characteristics that make them useful for many applications — including ultrasound machines and memory chips.

Researchers are currently investigating the use of perovskite in solar panels. The unique properties of perovskite theoretically allow for the manufacture of solar cells that could be cheaper and more efficient than silicon.

Some studies have demonstrated solar cell conversion efficiencies of up to 25.8% for perovskite, compared to 18%-22% for commercial silicon panels. The theoretical maximum efficiency for perovskite is even higher, up to 66%. Previous estimates of the top efficiency of perovskite were significantly lower — even greater efficiencies may be possible with further research.

By contrast, the theoretical efficiency limit for silicon cells is just 32.33%. This figure assumes the cells are capable of perfect absorption of solar energy. Scientists are unsure that efficiencies above 30% are even possible with real-world silicon cells.

Why the high efficiency of perovskite matters for solar energy

One of the most significant barriers to the widespread adoption of solar technology is the limited efficiency of available solar panels.

The average efficiency of a commercial solar panel has steadily climbed over the past two decades and continues to increase at a fairly rapid pace. The growth has been so fast that some companies recommend installers minimize the number of panels they store, as old stock may quickly become obsolete.

Some industry observers even believe solar energy may soon become efficient and cheap enough to threaten the industry’s growth — as a potential deflation of energy prices could make new solar arrays less of an economical investment.

Despite these improvements, the still-low efficiency of available solar panels has limited the potential return on investment for adoptees of new systems.

Greater efficiency could make solar technology a much more economical investment for consumers and businesses. Initiatives to fast-track the transition to green energy will also rely heavily on efficient solar technology — high-efficiency cells could make it possible to accelerate the global shift away from fossil fuel.

Challenges in manufacturing perovskite

Perovskite producers face three main challenges — material instability, toxic elements used in the manufacturing process and current-voltage hysteresis of perovskite cells. Existing methods produce cells that are extremely fragile and degrade in just a few minutes. They are also tightly controlled and carefully timed — otherwise, they could be made with rough surfaces and lower-than-average conversion efficiencies.

Researchers are currently working to make perovskite cells more durable. New manufacturing techniques that offer manufacturers additional leeway in process timing may also help businesses avoid rough surfaces and subpar perovskite.

Perovskite cells also suffer from current-voltage hysteresis — meaning it can vary significantly depending on if the cell’s voltage approaches maximum values or decreases from them. This hysteresis can considerably reduce the performance of the cell.

Hysteresis-free or low-hysteresis perovskite solar cells are possible, but new manufacturing techniques may be necessary to produce them.

The potential environmental impacts of perovskite cells

Toxic materials necessary for the manufacture of perovskite are another concern. Existing production processes generally require lead and its toxicity in at-scale production could have significant environmental impacts.

Consumers and businesses are driven by various factors when they decide to adopt solar power — including potential cost-savings and environmental benefits of renewable energy.

A solar cell technology with a “dirty” manufacturing process may make the product less appealing to customers wanting to reduce their personal impact.

Lead in manufacturing can also create serious health issues. Occupational lead exposure can cause acute and chronic conditions. Take-home lead exposure can also harm workers’ family members. As a result, the perovskite manufacturing plant that relies on lead could negatively impact local communities in several ways.

Researchers have identified multiple nontoxic replacements for lead. However, some of them cannot produce perovskite cells of the same efficiency as those manufactured with lead-perovskite.

Manufacturers need to develop a new approach that can keep perovskite stable and hysteresis-free while minimizing potential environmental impacts. Otherwise, the material’s drawbacks may limit its marketability and potential for commercialization.

How close are scientists to a perovskite breakthrough?

Researchers have developed several experimental manufacturing strategies that may potentially overcome many of the current challenges in developing perovskite. Additional research is necessary, but it seems like perovskite cells that are durable, hysteresis-free and nontoxic should be possible.

However, there are no current plans for the large-scale manufacture of perovskite cells. Further breakthroughs will likely be necessary before any company can begin to offer these solar cells for sale. Some companies plan to bring experimental perovskite offerings to market in the next few years, but nothing tangible is available yet.

The perovskite market is poised for strong growth over the next decade, according to researchers. However, those interested in the technology should expect to wait a few more years before manufacturers can produce panels that work.

Despite progress, commercial perovskite solar cells remain elusive

Perovskite solar cells could be more efficient than any other version currently available — but only if they can be manufactured at scale.

Scientists have made major advances in perovskite manufacturing, and more appear likely on the horizon. Current challenges, like hysteresis, cell durability and environmental impact, may all be solvable in the near future.

However, barring a significant breakthrough, perovskite cells aren’t ready for mass manufacturing just yet. It will likely be at least a few years before companies can bring these products to market, but at least progress is being made to get there.