hydrogen, green hydrogen

hydrogen, green hydrogen

The IEA is also calling for a boost in so-called blue hydrogen (hydrogen made in a facility including carbon capture and sequestration technology), of which it says we will need 197.6 million tons each year. The organization adds that 16 million tons of pink carbon (made with electricity from nuclear power) will be needed as well.

This total of 520 million tons of low-carbon hydrogen would be used across the industry, expanding hydrogen's adoption beyond its two main use cases today: chemical manufacturing and oil refinery.

The IEA reported that hydrogen manufacturing would have to grow at a CAGR of 66% during the 2020s, then at 23% from 2030 to 2050.

How is Green Hydrogen Produced?Green hydrogen is produced with electrolysis, a highly energy-intensive process that uses electricity to split water molecules into their component parts (hydrogen and oxygen molecules). When the electricity for this is obtained from renewable sources such as on-site solar or wind, it is green.

Electrolysis is more expensive and complicated than steam methane reforming (SMR), the technique used to produce the vast majority of hydrogen on the market today.

Electrolysis will always require more energy than it produces in terms of hydrogen fuel. This is an unavoidable fact and a consequence of the laws of thermodynamics: no new energy can be created in a system, and disorder will always increase, leading to less available or usable energy.

Typically, hydrogen produced with the electrolysis of water contains about 70% to 80% of the energy used to produce it.

Only 8 GW or 4% of global hydrogen production is made using electrolysis.

How are Blue and Gray Hydrogen Produced?

The standard method for producing hydrogen is SMR. When emissions from SMR hydrogen production are allowed to enter the atmosphere, the result is gray hydrogen. This is by far the most common hydrogen type on the market today.

The resulting hydrogen is called blue hydrogen if emissions are captured on-site using carbon capture and sequestration technology.

Between them, blue and gray SMR processes account for around 95% of all hydrogen produced today.

In SMR, natural gas is made to react with steam at extremely high temperatures to produce carbon monoxide and hydrogen. The equation for this reaction is given as follows:

CH4 + H2O ⇌ CO + 3 H2

After this reaction, the water gas shift (WGS) reaction makes additional steam react with carbon monoxide to produce more hydrogen and carbon dioxide molecules. The equation for the WGS reaction is as follows:

CO + H2O ⇌ CO2 + H2

These equations demonstrate the first part of hydrogen's carbon footprint problem: all of the carbon in the methane (CH4) that enters the plant is eventually converted into carbon dioxide (CO2). Four molecules of hydrogen (H2) are produced for each carbon dioxide molecule, with the steam added in the second step providing the extra hydrogen molecules.

Essentially, this is why gray hydrogen has such a large carbon footprint. However, blue and gray hydrogen also create greenhouse gas emissions in the second part of the problem.

This is because each process requires large amounts of energy, generating steam, heating the reactor, cooling material, etc.

There are 280 g of carbon dioxide emissions for every kilowatt-hour of hydrogen energy produced for gray carbon.

This equation only takes hydrogen production into account. Once hydrogen is produced, it still has to be compressed, transported, combusted, or converted into a fuel cell to be a valuable energy source. Fuel cells also need to be manufactured themselves, further adding to the hydrogen's potential carbon footprint.

Can Hydrogen Help Cut Greenhouse Gas Emissions?

Even though hydrogen fuel burns clean, emitting no carbon dioxide or any other greenhouse gas when used, its suitability as a sustainable energy choice remains debatable.

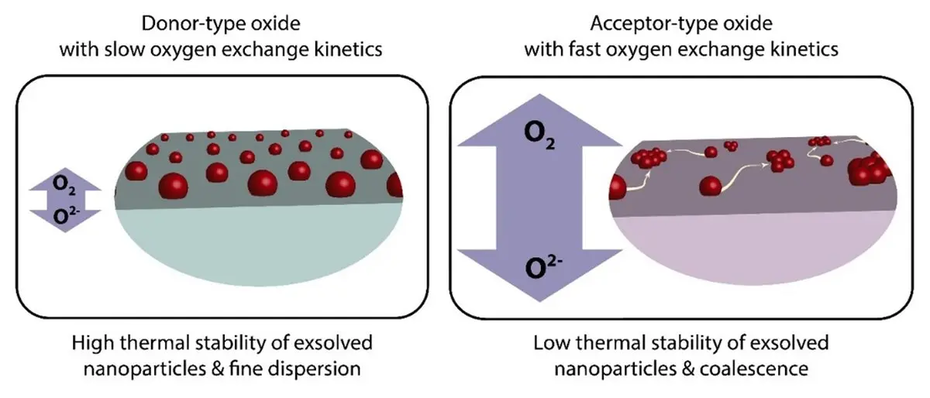

Hydrogen production is still a relatively immature field. The maximum energy conversion efficiency rates achievable for green carbon today (70% to 80% of the renewable electricity they consume) will increase as technology progresses.

Infrastructure improvements and network benefits would also follow wide-scale investment in an infant green hydrogen industry. As well as increasing efficiency in the entire system, these would create opportunities to use clean-burning hydrogen fuel in many industries and economic sectors.

With improved efficiency, better technology for storage and transportation, and more investment in advanced facilities with on-site renewable energy sources, green hydrogen is a possibility. For many, including the IEA, this is a necessity.