Natron's sodium-ion batteries have an enormous cycle life, practical power density, excellent safety and super-fast charging, without using any lithium. Through a partnership with Clarios, they'll go into mass manufacture in Michigan next year.

Current battery tech is headed for a lithium crunch, according to some experts, with the vast majority of the world's supply chain owned by China and simply not enough lithium in known reserves to meet projected levels of demand for the electric vehicle market – let alone all the other sectors that are looking to move to battery power in the coming years.

Alternatives will thus be absolutely pivotal, where their performance characteristics make sense, and sodium-ion battery projects have been popping up regularly over the last several years that aim to chip off little bits of the battery market. Notably, China's CATL launched a sodium-ion battery last year aimed at the electric vehicle market, with a specific energy of 160 Wh/kg – more than half the density offered by today's mass-market lithium-ion packs.

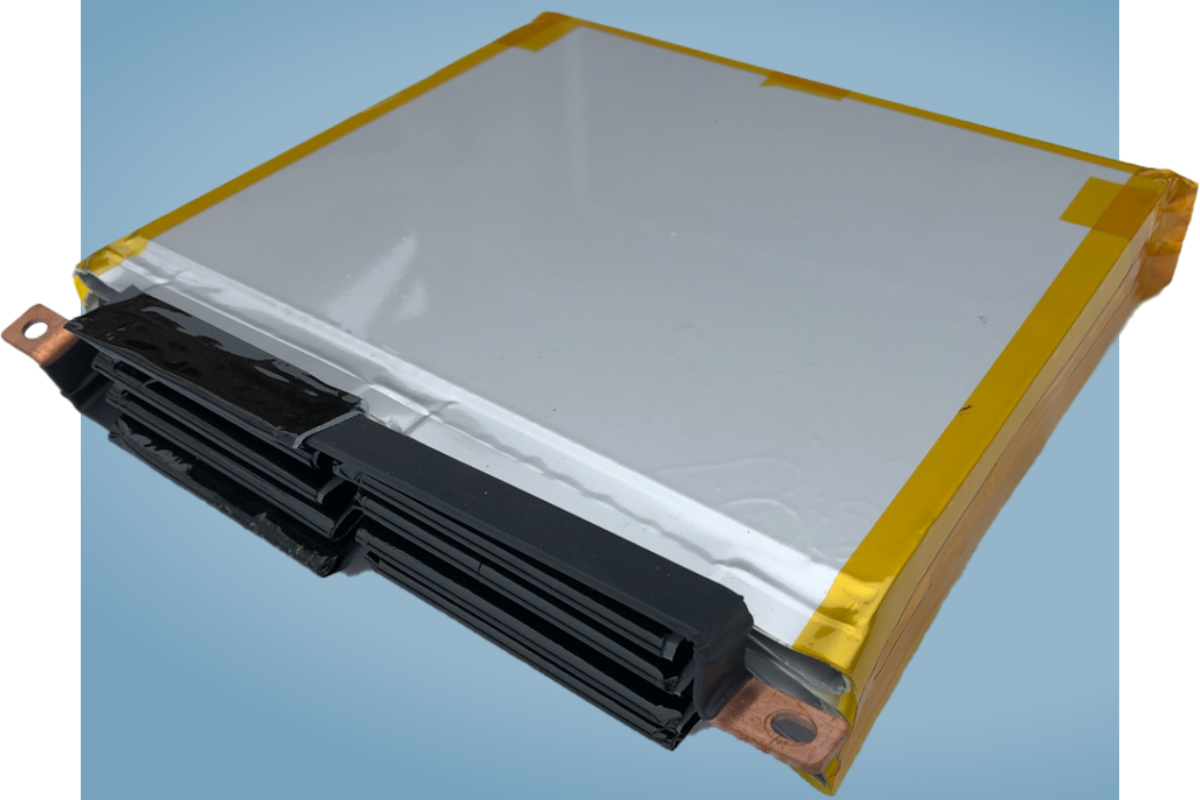

California company Natron has chosen a different target, using a different chemistry based on Prussian Blue, a commonly produced pigment best known for providing the blue color that gave blueprints their name, as well as being extensively used in traditional Japanese woodblock prints like Hokusai's The Great Wave off Kanagawa.

Battery designs tend to be a compromise between many factors, including thermal performance, energy and power density by weight and volume, safety, charging time and cycle life. Natron claims its design offers a strong volumetric power density in between that of lead-acid and lithium-ion, with super-fast charging enabling 0-99 charges in as little as eight minutes, and a monster lifespan over 50,000 cycles – between five and 25 times greater than lithium-ion competitors. They're also said to be extremely thermally stable, making them safe to transport, deploy and dispose of without risk of fire.

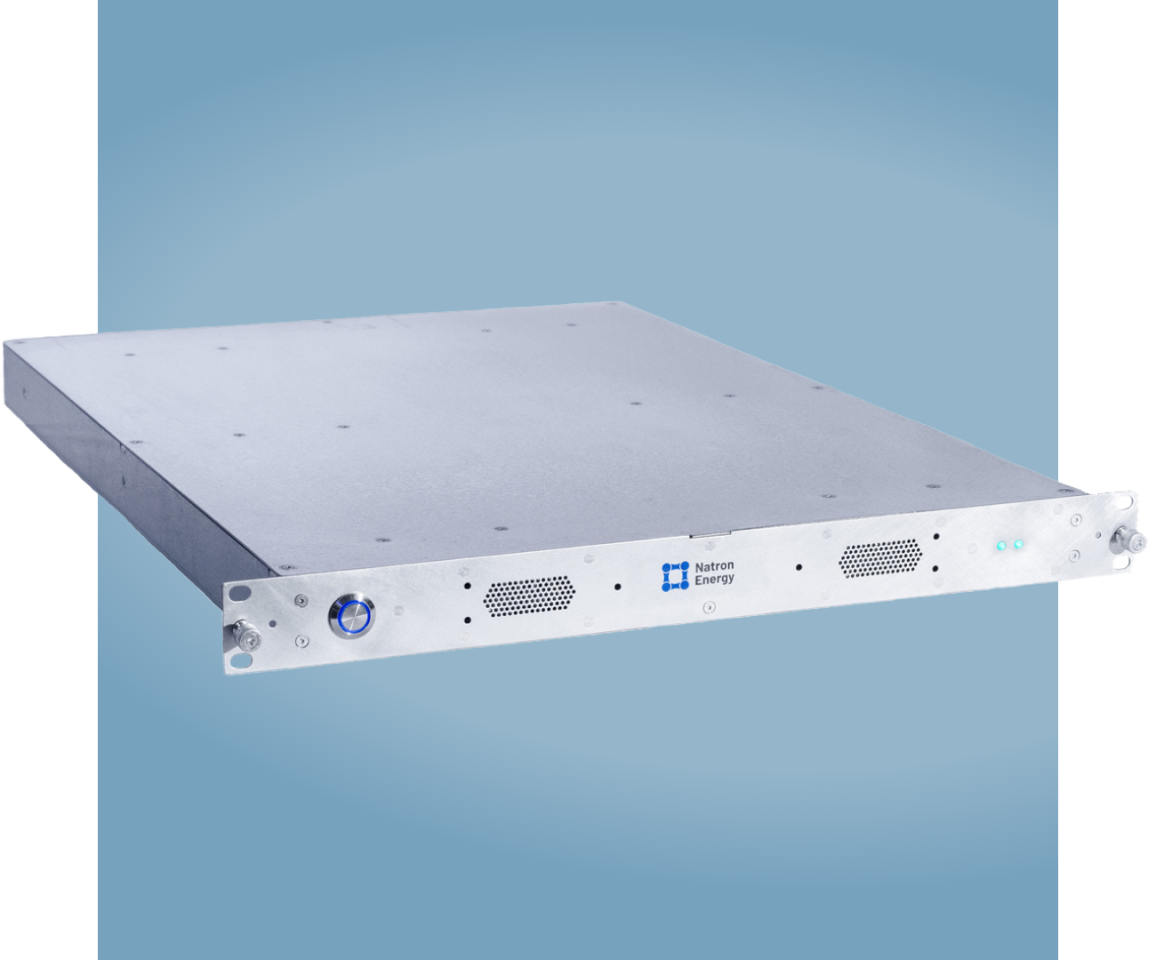

We can assume that energy density is relatively low by both weight and volume – Natron is not pitching this product at EV manufacturers for whom size and weight are critical parameters. Instead, Natron is targeting industrial battery use cases: data center backup power, forklifts and other industrial vehicles, telecommunications installations and the like. There may be some EV applications as well – for example, as a buffer battery in EV charging stations, storing up energy between the slow grid supply and the fast chargers that'll pump it into car batteries as fast as possible.

Natron has gone into partnership with Clarios International to bring these sodium-ion batteries to mass production beginning in 2023 at the Clarios Meadowbrook facility in Michigan. This is currently a lithium-ion battery facility, and Natros says its sodium-ion technology can be manufactured using the same equipment, so the partnership allows Natron to get these things to market faster and cheaper than building its own facility from the ground up. When production begins, Natron says this will be the world's largest sodium-ion battery plant.

The wide availability of the materials required, says Natron, should lead to very stable pricing – and that could prove to be a key advantage over lithium depending on what happens with supply and geopolitics in the coming decades. Check out a short presentation below.