GE on May 25 announced the proposals, which were selected by DOE’s Office of Fossil Energy and Carbon Management, are worth more than $12 million. GE on Wednesday said the work will “accelerate the path towards a a 100% hydrogen combustion future.”

The projects will support the recent “utility-scale” gas turbine demonstration of GE’s H-Class turbine utilizing hydrogen at the Long Ridge Energy Terminal, a large multimodal facility in Hannibal, Ohio. Long Ridge, located on the border of Ohio and West Virginia, entered commercial operation in October 2021.

“We applaud the DOE’s leadership, commitment and investment in hydrogen combustion,” said Jeffrey Goldmeer, Emergent Technologies Director at GE Gas Power. “The investments the agency is making will help us accelerate the development and testing of retrofittable F-class combustion systems capable of operation on 100% hydrogen using a combination of micro mixer and axial fuel staging technologies.”

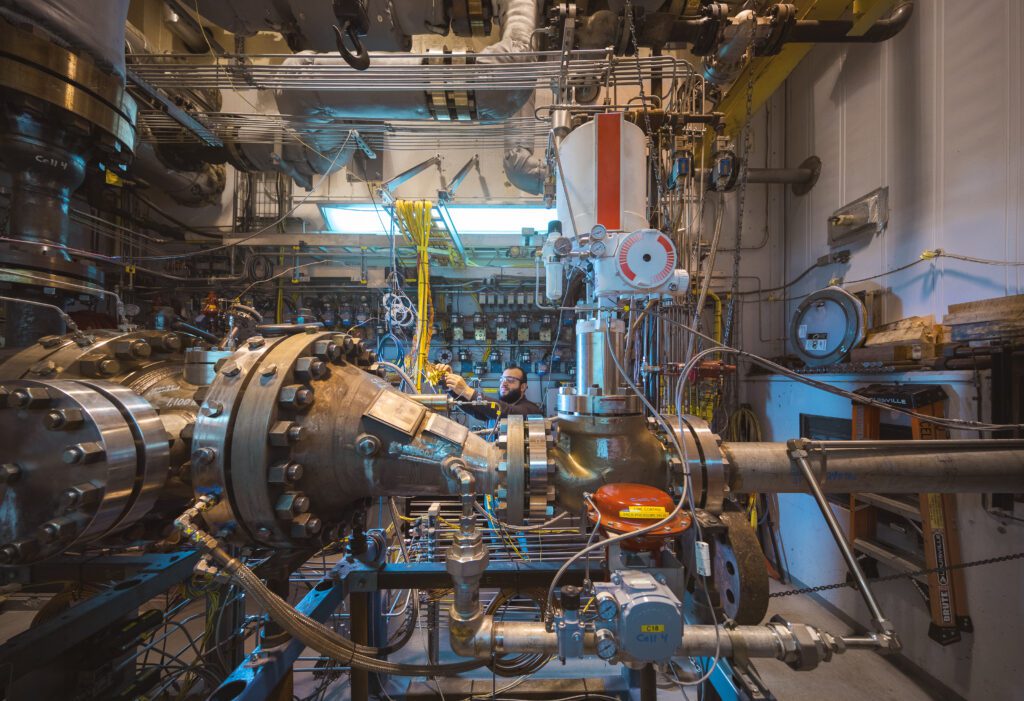

This GE Research Combustion, or GRC, test cell is among 10 such units being used by the company for advanced combustion research and development at GE’s Research Combustion Laboratory in Niskayuna, New York. Courtesy: GE

DOE Funding

GE’s projects are among six proposals that would receive a total of $25 million in federal funding that was announced by the DOE last week. GE on Wednesday said the awards “represent another key milestone in GE’s efforts to advance hydrogen technologies for gas turbines and combined cycle power plants, which will help achieve significant reductions in carbon emissions.”

The April commissioning of Long Ridge opened the door to a demonstration of the first advanced class hydrogen-burning power plant. Long Ridge is powered by a GE 7HA.02 gas turbine, which can burn up to 20% hydrogen by volume in the gas stream initially, with GE’s technology roadmap developed to burn more hydrogen over time.

GE is researching high hydrogen combustion through its Gas Power business and its Research Lab, with the Gas Power engineering team working in Greenville, South Carolina. The Research Lab is located in Niskayuna, New York. GE said the engineering groups have “decades of hydrogen experience and [utilize] fully capable build-and-test facilities for studying hydrogen combustion and flame characteristics.”

Keith McManus, who leads the Combustion Team at GE Research and is leading GE Research’s project, said advancing the integration of hydrogen would increase power plant efficiency.

“As everyone close to hydrogen technology knows, the technical challenges are considerable when you’re talking about being able to run a turbine on 100% hydrogen. Having worked on hydrogen combustion technologies for many years, we are aware of the many challenges and have made considerable progress over time,” said McManus. “Working in cooperation with the DOE, we’re confident we can make even more strides that get us closer to 100%.”

Research Division Project

GE on Wednesday said the Research division’s project totals close to $7 million. The group is studying the operation of hydrogen-fueled turbine components on special rigs in its combustion test facility in Niskayuna. The group will examine how gas turbine efficiency can be improved for both simple- and combined-cycle power generation applications.

GE Gas Power’s award, totaling nearly $6 million, “will focus on the study of highly reactive hydrogen fuels and addressing the challenges associated with this type of combustion dynamics,” according to GE, which said that as part of that program, the project team will develop and test gas turbine components with natural gas-hydrogen fuel mixtures and up to 100% hydrogen.

The DOE and GE have collaborated over the past several years to research and develop combustion solutions for more sustainable power generation. GE’s DLN2.6e combustion system, which is standard on current GE HA gas turbines, was developed as part of the DOE’s High Hydrogen Turbine program.

The technology has enabled the DLN 2.6e combustion system to operate on blends of natural gas and hydrogen. GE said it has developed a “technology roadmap to achieve 100% hydrogen in this platform in the next decade.” The company on Wednesday said it has more than eight million operating hours on hydrogen and similar low-BTU fuels from more than 100 units.