European Energy - designated by Maersk as a key supplier of e-methanol to ensure their shipping fleet undergoes a green transition away from traditional bunker fuel - is set to deliver 200,000-300,000 tons of e-methanol to the shipping giant annually by 2025.

To achieve this, European Energy is developing the world´s first large scale commercial e-methanol production facility. The green hydrogen will be provided by a 50MW electrolyzer and it will be compressed by Howden.

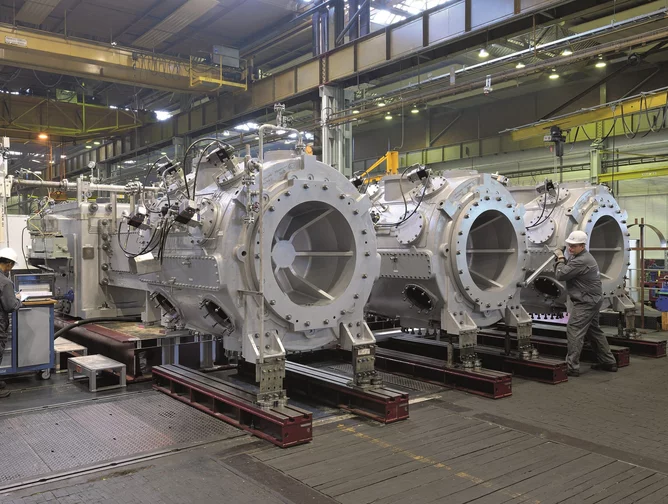

Howden will supply five compressor packages, which provide the required hydrogen purity, pressure and flow capacity levels on demand. The turnkey packages require minimal onsite installation and the compressors are easy to maintain throughout their lifecycle.

The compact design combines high-level engineering expertise with a minimal footprint, with highly reliable, non-lubricated piston compressor technology delivering 1,370 kg/hr of green and pure hydrogen to support a significant reduction in CO2 emissions.

Salah Mahdy, Global Director of Renewable Hydrogen at Howden, said while renewable energy is becoming more common in the heavy transportation industry, this project marks the beginning of CO2-neutral shipping at a large-scale, and is a significant step towards ocean vessels and the maritime industry using 100% renewable energy.

“The International Maritime Organisation has targets to cut the global shipping industry’s annual greenhouse gas emissions by at least half by 2050, compared to 2008 levels, so renewable energy options like those provided by Howden hydrogen compressors play a vital role in meeting these goals," he said.

Anders Brendstrup, Head of EPC in PtX at European Energy, said collaboration with partners across the industry is necessary for creating a value chain, scaling green fuel production, and planning future total cost of ownership.

"This also requires cost efficiency, reliability and safety," he said. "Using Howden’s compression systems to connect renewable energy production and electrolysis with transmission and distribution is a key step for us. Howden’s contribution will make our ambition to support zero-emission mobility through an unparalleled technologic approach a safe and realistic goal.”

Howden's technology can handle and optimise hydrogen across the value chain from production, to storage, distribution and end use such as refuelling stations, Power-to-X applications and heavy industrial purposes.

Howden Select provides free digital compressor selection software

Howden has launched a new and improved compressor selection software, Howden Select, for customers globally. The free online digital tool allows users input their selection criteria and generates the most suitable product selection tailored to user needs.

The development follows a period of intense system upgrades including new features, improved usability and intuitive navigation. Led by their in-house digital software team, the new Howden Select centres around customers’ needs and functionality which empowers customers to generate their own instant product selections.

The team has advanced the software to handle more complex sales enquires with additional insights and features, including access to product manuals and datasheets.

Douglas Latta, Screw Compressor Product Director at Howden, said it marks an important point in its digital transformation journey.

"Howden’s digital solutions are designed to give our customers a data driven advantage, and the launch of our new platform provides our customers with unlimited access to our software, making it a convenient way to engage with our own applications and sales teams," he said.

"Our users can create product selections in real time, making it an efficient way to generate results tailored to your needs. This will revolutionise the way we do business in the future and will improve the service and speed of which we can support our customers around the world."

Last month Howden opened a new Hanoi office, complementing its existing location in Ho Chi Minh City, bringing greater access to procurement, quality control, technical assistance and project execution in northern Vietnam.

RWE and SGN announce green hydrogen partnership for domestic heat in Scotland

An MoU has been signed between RWE and SGN to explore the development of electrolysers, powered by RWE’s 10 onshore wind farms in Scotland which have a combined capacity of 213MW, to supply homes and businesses with hydrogen gas via Scotland’s gas network.

The partnership will investigate the decarbonisation of homes and businesses connected to the networks of Campbeltown, Stornoway, Oban, Thurso and Wick, which are not connected to the mains gas network.

These networks are currently supplied by Liquified Natural Gas (LNG) and Liquified Petroleum Gas (LPG), which when swapped with hydrogen could save 21,000 tonnes of carbon each year and decarbonise around 9,500 properties.

The partnership will define how much hydrogen is needed, the requirements to convert these networks to hydrogen, and the supply of green electrolytic hydrogen from RWE’s renewable onshore wind farms nearby. In doing so, the project could also unlock onshore wind farm developments in grid-constrained areas, by providing a use for the green electricity generated.

A feasibility study will also be conducted over the coming months into a 100MW electrolyser at RWE’s Markinch CHP biomass plant. This could produce green hydrogen from local and grid connected renewable energy, to connect into SGN’s gas network in Fife. It would build on the work SGN is already undertaking in Levenmouth on their world-first H100 Fife project.

Steve Boughton, RWE Director Hydrogen Development, said: “This MoU is a perfect partnership to develop options for the decarbonisation of domestic and business gas networks, and to help Government achieve its ambitions for 10GW of hydrogen production. Hydrogen will play an essential role in the pathway to net zero, particularly in industry and homes which are hard to decarbonise, and RWE is perfectly positioned to support the development of the UK hydrogen economy.”

Fergus Tickell, SGN System Transformation and Business Development Lead, said: “We’ll explore how hydrogen produced locally can be delivered through the world-class networks we’ve been operating for decades, to all of Scotland’s communities, including in Fife, Campbeltown, Stornoway, Oban, Thurso and Wick. We also look forward to investigating more opportunities across the UK.”