Their optimization framework can considerably decrease the cost of evaluating how battery configurations will function over the long pull.

The goal is to design a better battery and, traditionally, the industry has tried to do that using trial and error testing. It takes such a long time to evaluate.

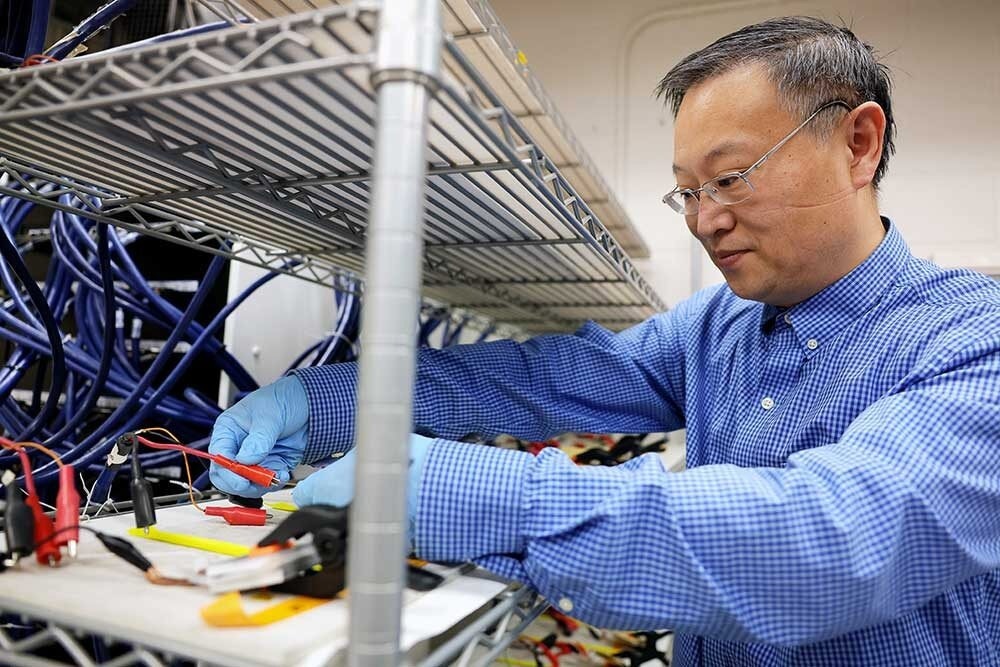

Wei Lu, Professor, Mechanical Engineering, University of Michigan

Lu was behind the framework and also the leader of the research team. The study has been reported in the journal Patterns-Cell Press.

Electric vehicle (EV) battery manufacturers often struggle with a range of anxiety and worries regarding charging availability. Thus, the optimization system fabricated by Lu’s team could reduce the time for both physical testing and simulation of new and better batteries by around 75%.

That speed could be of significant advantage to battery developers looking for the correct combination of materials and configurations. This helps guarantee that consumers always have the capacity to reach their destinations.

As far as battery design is concerned, parameters include everything right from the materials utilized to the thickness of the electrodes to the size of the particles in the electrode and more.

Generally, testing each configuration implies several months of fully charging and then completely discharging—or cycling the battery—1,000 times to copy 10 years of use. It is extremely laborious to repeat this test through the huge number of possible battery designs to pick out the best ones.

Our approach not only reduces testing time, but it automatically generates better designs. We use early feedback to discard unpromising battery configurations rather than cycling them till the end. This is not a simple task since a battery configuration performing mediocrely during early cycles may do well later on, or vice versa.

Wei Lu, Professor, Mechanical Engineering, University of Michigan

Lu added, “We have formulated the early-stopping process systematically and enabled the system to learn from the accumulated data to yield new promising configurations.”

To achieve a sizable reduction in the time and cost, engineers from U-M combined the latest in machine learning to design a system that is well aware of both when to quit and how to get better as it goes.

The framework stops cycling tests that do not have a hopeful start and saves resources with the help of the mathematical methods called Asynchronous Successive Halving Algorithm and Hyperband. At the same time, it takes data from earlier tests and idedntifies new promising parameters to analyze with the help of Tree of Parzen Estimators.

Besides cutting off tests that run short of promise, a main time-saving element in U-M’s system is the way it produces multiple battery configurations to be tested simultaneously, called asynchronous parallelization.

If any configuration is done in testing or is being discarded, the algorithm instantly evaluates a new configuration to test without the necessity to wait for the outcomes of other tests.

The framework of U-M seems to be effective in testing all battery designs, from those utilized for decades to run internal combustion automobiles, to the smaller products that power the cell phones and watches. However, EV batteries might constitute the most pressing use of the technology.

“This framework can be tuned to be more efficient when a performance prediction model is incorporated. We expect this work to inspire improved methods that lead us to optimal batteries to make better EVs and other life-improving devices,” stated Changyu Deng, U-M doctoral student in mechanical engineering and first author of the paper.

A recent survey performed by Mobility Consumer Index displayed that 52% of consumers are currently taking an EV into account for their next vehicle purchase. Despite altering attitudes, concerns tend to remain over vehicle range (battery capacity) and the number of charging stations that are available to drivers.

Hence, battery performance has a vital role in bringing EVs to the masses as a way of offsetting the effects of climate change.

By significantly reducing the testing time, we hope our system can help speed up the development of better batteries, accelerate the adoption or certification of batteries for various applications, and expedite the quantification of model parameters for battery management systems.

Wei Lu, Professor, Mechanical Engineering, University of Michigan

The study was financially supported by the LG Energy Solution.