Ultra Safe Nuclear Corporation, which is working to deploy a gas-cooled micro reactor, said it has a new supplier agreement with Korean EPC firm Hyundai Engineering Co.

Hyundai Engineering will leverage its supplier network to procure materials and services for Ultra Safe Nuclear’s micro reactor projects globally. The agreement, signed in Ottawa, Canada, builds on ongoing collaboration between the two companies.

Seattle-based Ultra Safe Nuclear said the new deal strengthens its reach in international markets.

The companies also signed an MoU to build on Ultra Safe Nuclear’s fuel technology and develop a multi-purpose high temperature reactor suitable for power production and process heat applications. This will include, but not be limited to the production of hydrogen.

“We are seeing tremendous interest in our micro reactor for a growing number of power and industrial process heat applications,” said Francesco Venneri, CEO of Ultra Safe Nuclear.

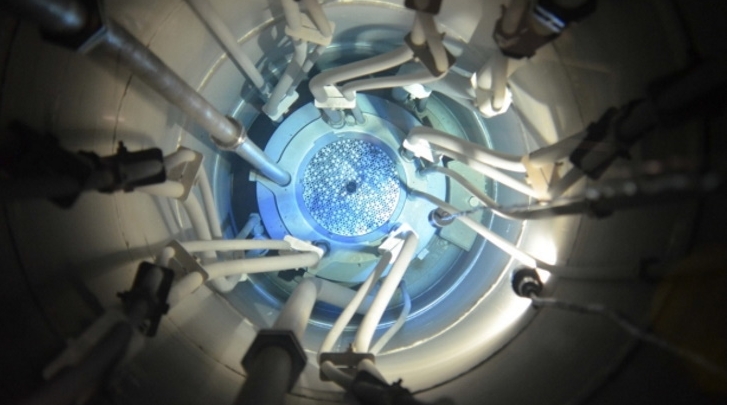

Ultra Safe Nuclear’s ceramic microencapsulated (FCM) fuel consists of microencapsulated coated fuel particles embedded in a silicon carbide matrix. FCM technology development efforts have mostly been conducted at Oak Ridge National Lab as part of the DOE’s Office of Nuclear Energy Advanced Fuels Campaign.

The Oak Ridge Lab will be the site of the reactor company’s new fuel production facility.

The PFM (Pilot Fuel Manufacturing) facility is expected to produce TRISO and ceramic microencapsulated nuclear fuel, designed for use in advanced reactors.

Ultra Safe Nuclear has said it will be able to process uranium powder into fuel particles onsite, producing multiple kilogram quantities of fuel and helping it scale up its fuel-production capabilities.

Other announced projects from Ultra Safe Nuclear include a full-scale demonstration micro reactor at Chalk River Laboratories in Canada and a research and test micro reactor at the University of Illinois at Urbana-Champaign.