By transforming carbon dioxide (CO2) into fuels and other valued chemicals at affordable prices on an industrial scale, a new technology developed at the University of Waterloo can make an important difference in the fight against climate change.

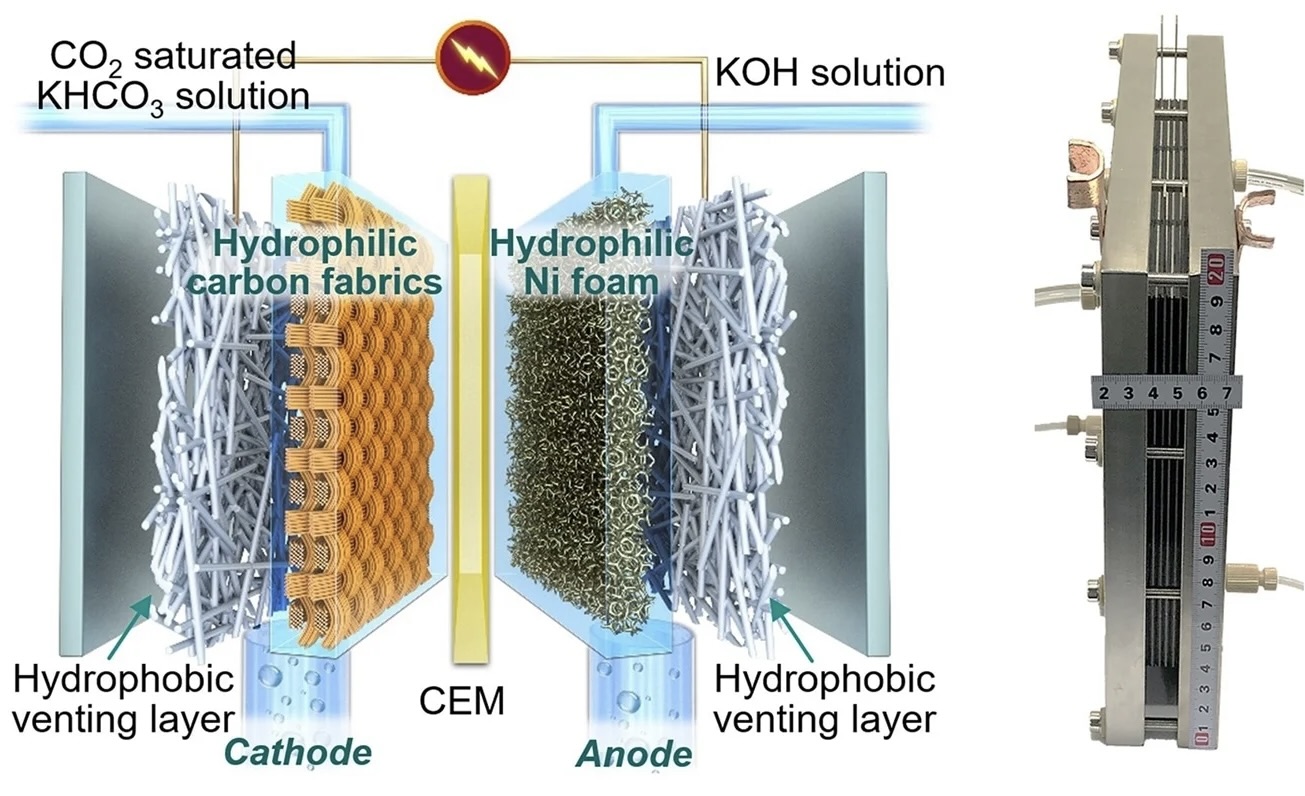

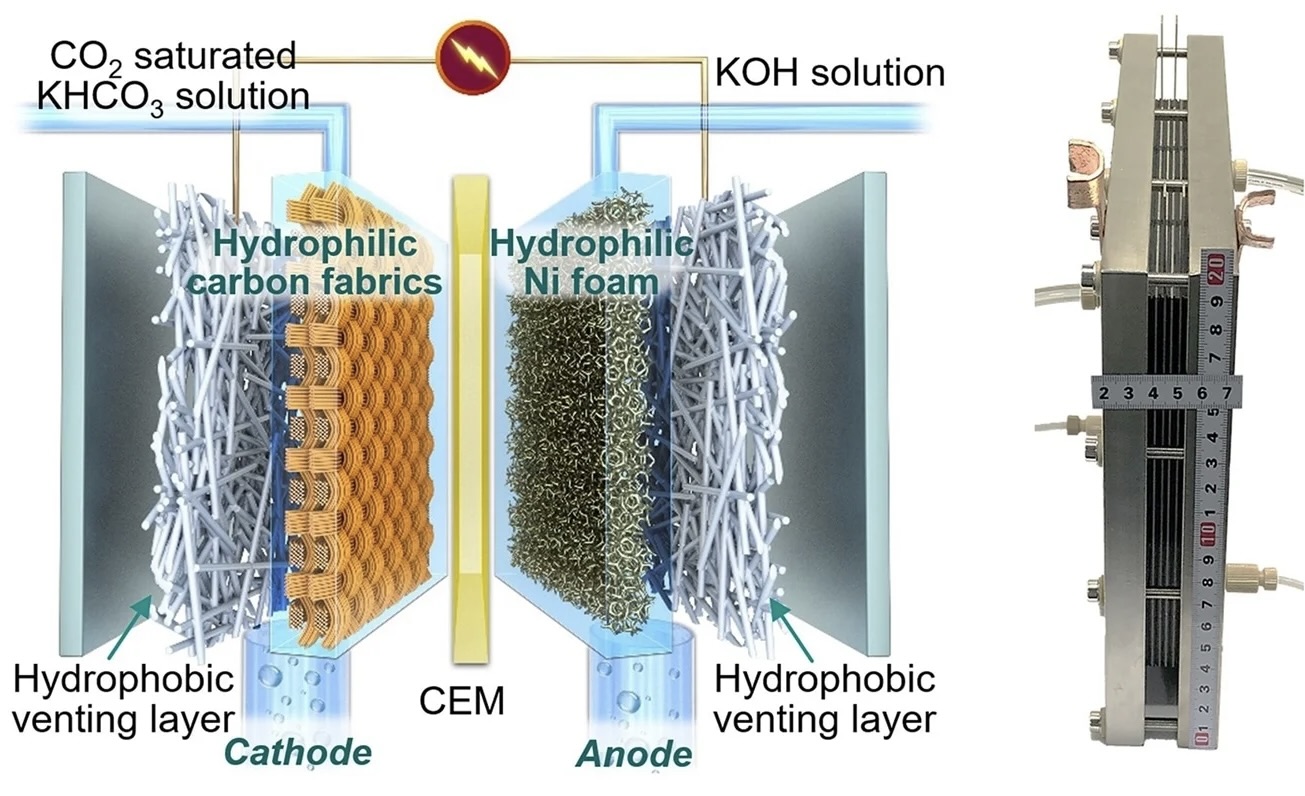

Left: a schematic showing the key components of the reactor and working mechanism. Right: a picture of the CO2 stack, which is a demonstration of the commercial reactors. Image Credit: University of Waterloo

Left: a schematic showing the key components of the reactor and working mechanism. Right: a picture of the CO2 stack, which is a demonstration of the commercial reactors. Image Credit: University of Waterloo

The system produces 10 times more carbon monoxide (CO)—which can be utilized to create methane, ethanol, and other useful elements—than that presently produced by small-scale technologies. This was outlined in a study published in the journal Nature Energy.

Also, its individual cells can be stacked to create reactors of any size, which make the technology a tailor-made, economically feasible solution that can be implemented on-site, for instance at factories with large CO2 emissions.

This is a critical bridge to connect CO2 lab technology to industrial applications. Without it, it is very difficult for materials-based technologies to be used commercially because they are just too expensive.

Dr Zhongwei Chen, Professor, Chemical Engineering, University of Waterloo

The system is equipped with devices called electrolyzers that transform CO2, a key greenhouse gas formed by burning fossil fuels, into CO with the use of electricity and water.

Electrolyzers built by the scientists have the latest electrodes and a new type of liquid-based electrolyte, saturated with CO2 and converting it into CO through an electrochemical reaction.

Fundamentally, their electrolyzers are 10 X 10 cm cells, which are several times bigger than current devices and could be configured or stacked in reactors of all sizes.

This is a completely new model for a CO2 reactor. It makes the whole process economically viable for industrialization and can be customized to meet specific requirements.

Dr Zhongwei Chen, Professor, Chemical Engineering, University of Waterloo

Dr. Chen is also the Canadanian Research Chair in Advanced Materials for Clean Energy at the University of Waterloo.

The scientists foresee on-site reactors at coal-fired factories and power plants which would be given CO2 emissions directly, lowering costs further by removing the requirement to collect and capture CO2 first.

Contributing to the ecological advantages, they are also planning to charge the reactors with sources of on-site renewable energy like solar panels.

“I’m excited by the potential of this technology,” Chen stated. “If we really want to make a difference by reducing emissions, we have to concentrate on reducing costs to make it affordable.”

Postdoctoral Fellow Dr. Guobin Wen and Chemical Engineering Professors Dr. Aiping Yu and Dr. Jeff Gostick are included among Chen’s collaborators at Waterloo. Many scientists at the South China Normal University also contributed.