JERA Co. Inc., Japan’s largest power generation company, announced the signing of a memorandum of understanding (MOU) “for potential collaboration for the joint project development and sales & purchase of clean ammonia” with CF Industries Holdings Inc., the world’s largest producer of ammonia.

Under the MOU, JERA and CF Industries have agreed “to jointly study the viability to collaborate” in the following areas:

Separately, JERA signed a similar agreement with Yara Clean Ammonia Norge AS, which is a subsidiary of Yara International ASA, an Oslo, Norway–headquartered producer of ammonia. It, too, is considering development of a new project along the U.S. Gulf Coast.

The companies announced the deals on Jan. 17, after JERA completed a tender process that it said had begun on Feb. 18, 2022. CF Industries reported that its agreement requires the ammonia to be produced with at least 60% lower carbon emissions than conventionally produced ammonia. Termed “clean ammonia,” co-firing the fuel with coal at JERA’s Hekinan Thermal Power Station is expected to substantially reduce carbon dioxide (CO2) emissions from the facility. (Ammonia does not emit CO2 when combusted.)

“We are pleased to continue to build our relationship with JERA as we advance our shared commitment to accelerate the world’s transition to clean energy,” Tony Will, president and CEO of CF Industries Holdings Inc., said in a statement issued to POWER. “Our leading ammonia production network and disciplined investments in clean energy initiatives have positioned CF Industries at the forefront of clean ammonia supply. We look forward to helping JERA and Japan meet its clean ammonia requirements, which represent the first significant volume of what we believe will be substantial global demand for clean ammonia as a clean energy source,” Will added.

Transporting Hydrogen

The chemical formula for ammonia is NH3. For power companies, the most important part of that formula is hydrogen. “Hydrogen is really being looked at as a key means of transporting energy around the world and fueling the world in an environment where carbon emissions aren’t acceptable,” Erik Mayer, vice president of Clean Energy Solutions with CF Industries, said as a guest on The POWER Podcast last year.

“We convert large quantities of hydrogen into ammonia, currently for the fertilizer market but ultimately that same ammonia molecule is being looked at as an efficient way of being able to move hydrogen molecules around the world, whether they’re sourced from natural gas or whether they’re sourced from electrolysis,” Meyer said.

He explained that the advantage ammonia offers over hydrogen is that it is a liquid at moderately low temperatures and can be stored as liquid under relatively low pressure, similar to how liquefied petroleum gas (LPG) is stored. Concerning how the ammonia is used, Mayer said there are two possible ways: ammonia can be burned directly or it can be “cracked,” that is, decomposed over a catalyst, back to hydrogen.

“Some power generators, particularly in Japan, are looking at co-firing ammonia in coal-fired plants where they could replace say 20% of the coal they would burn with ammonia and essentially reduce the coal plant’s emissions by 20%,” said Mayer. “That technology is being proven in a pilot test that is relatively understood and known to work.”

Co-Firing Demonstration Project

JERA has been partnering with Japanese engineering company IHI Corp. on what was originally expected to be a four-year test project that began in June 2021. Utilizing a grant program funded at least partly by Japan’s New Energy and Industrial Technology Development Organization (NEDO), the demonstration project is intended “to establish technology for the large-volume co-firing of fuel ammonia at the Hekinan Thermal Power Station.”

JERA was tasked with ammonia procurement and construction of related facilities, such as the storage tank and vaporizer, while IHI’s role was to develop the burners to be used in the demonstration. As the project kicked off, JERA noted it was the “world’s first demonstration project in which a large amount of ammonia will be co-fired in a large-scale commercial coal-fired power plant.”

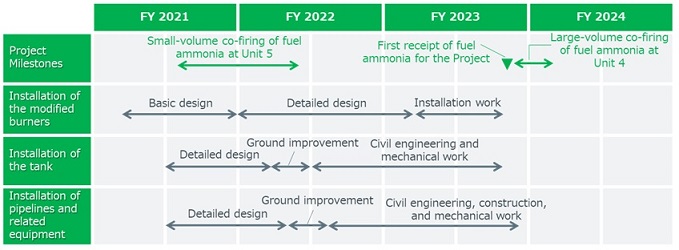

By October 2021, the two companies had already begun small-volume utilization of fuel ammonia in Unit 5 at the Hekinan station, the purpose of which was to help in the development of a co-firing burner to be used for large-volume utilization at Unit 4. The test replaced two of the 48 burners at Unit 5 with test burners to examine the effects of different burner materials and combustion times over a six-month period to identify the required conditions for co-firing burners. The testing was expected to require about 200 tons of ammonia.

With the project making steady progress, JERA and IHI announced on May 31, 2022, that they had shorten the installation period for the burners, tank, pipes, and other equipment required for the project. Therefore, they decided to move up the start of large-volume co-firing of fuel ammonia at Unit 4 by approximately 1 year (Figure 1). With the MOU announcements on Jan. 17, ammonia procurement now seems to be moving up the list of priorities.

1. Project schedule update issued May 31, 2022. Courtesy: JERA

Clean Ammonia

CF Industries has been working on a couple of industry-leading projects of its own, intended to decarbonize its ammonia production network. In October last year, the company entered into a commercial agreement with ExxonMobil to capture and permanently store up to 2 million metric tons of CO2 emissions annually from its manufacturing complex in Louisiana. That project includes a $200 million investment to build a CO2 dehydration and compression unit at CF Industries’ Donaldsonville, Louisiana, facility to enable captured CO2 to be transported and stored.

ExxonMobil will then transport and permanently store the captured CO2 in secure geologic storage it owns in Vermilion Parish. As part of the project, ExxonMobil signed an agreement with EnLink Midstream to use EnLink’s transportation network to deliver CO2 to permanent geologic storage. Schedulers expect the project to start-up in early 2025.

Additionally, in April 2021, CF Industries signed an engineering and procurement contract with thyssenkrupp for a “green ammonia” project at the Donaldsonville manufacturing complex. For that project, thyssenkrupp will supply a 20-MW alkaline water electrolysis plant that will use renewable energy to produce green hydrogen. CF Industries expects to integrate the carbon-free hydrogen generated by the electrolysis plant into existing ammonia synthesis loops to enable the production of 20,000 tons per year of green ammonia beginning in 2024.

Meanwhile, the company has also commenced a front-end engineering and design study to construct a greenfield clean ammonia facility utilizing carbon capture and sequestration in Ascension Parish, Louisiana. Demand for green and blue ammonia is expected to grow significantly as a decarbonized energy source for hard-to-abate industries. CF Industries expects to market up to 1.7 million metric tons of blue ammonia annually. A final deal with JERA could put it well on its way to reaching that goal sooner rather than later.

JERA Corporate Vice President Yukio Kani said: “We are pleased to work together with CF Industries on this significant journey towards decarbonizing the industry, and I am confident that CF Industries’ reliable operational capabilities that formed its track record for safe and efficient production as the world’s largest ammonia producer will profoundly contribute to JERA’s structuring of the clean fuel ammonia value chain. JERA will continue its own efforts as well as to take hands with our partners in pursuit of our endeavor to realize and accelerate not only the decarbonization of the Japanese energy industry but also to solve the energy-related issues that the world is facing.”