The Fraunhofer Institute for Physical Measurement Techniques (Fraunhofer IPM) is in the process of developing a novel method for the inline monitoring of lithium concentration as a tool for geothermal lithium extraction. The LiMo project is being designed to complement the sorption-based extraction process that has been developed by Karlsruhe Institute of Technology (KIT).

The inline monitor is based on laser-induced breakdown spectroscopy (LIBS), an established materials analysis method that uses short pulse laser to transfer a minute part of material into plasma for spectral analysis. The team at Fraunhofer IPM will refine this method to make it suitable for conditions typical in geothermal surface facilities – liquid at 20 bar and 90 degrees Celsius.

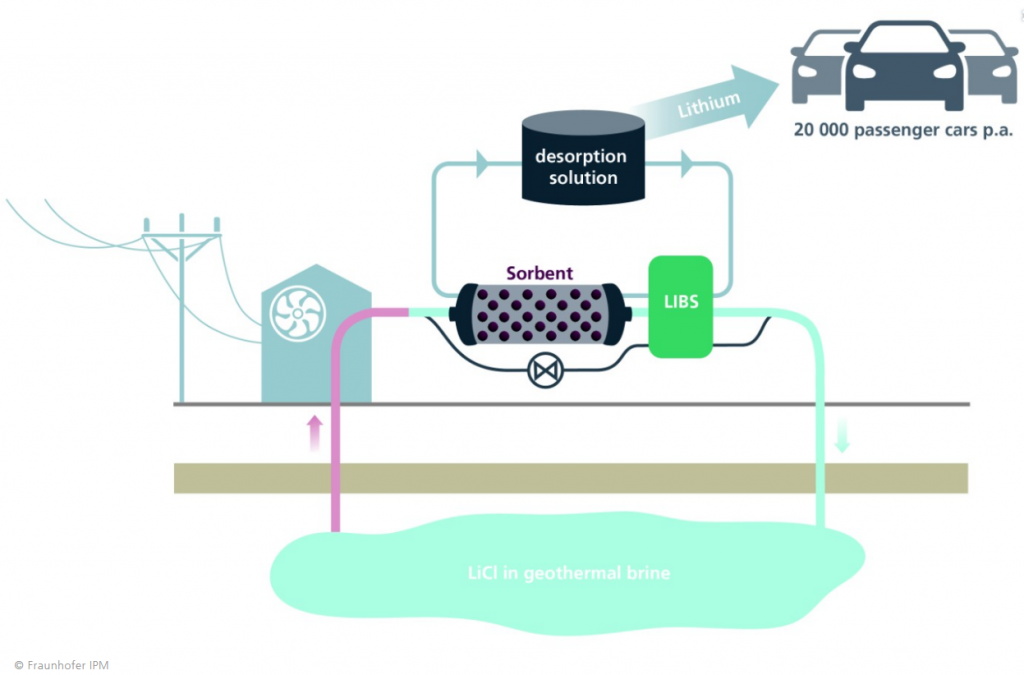

KIT has developed a method for extracting lithium from geothermal brine using a sorption process. The brine is led through a reactor filled with lithium-selective sorbent, thus binding the lithium. The sorption speed depends on a number of parameters, such as the composition of the thermal water, its pH value, its lithium concentration and the f low rate.

Once the sorbent is saturated, the direction of flow is reversed and a desorption solution separates the lithium from the adsorber. For an efficient and viable lithium extraction, the time the direction of flow is reversed must be precisely controlled based on when the saturation limit of the adsorber is achieved.

The saturation can be deduced from the lithium concentration downstream from the reactor, a measurement that until now has required cumbersome laboratory processes. This is precisely the gap that the LiMo project seeks to bridge. With an inline monitor, the extraction process can be made more effficient.

The LiMo project (inline lithium monitoring for the efficient extraction and process control of lithium from geothermal brine and recycling material) is funded by the Ministry of Economic Affairs, Labor and Tourism of the federal state of Baden-Württemberg, Germany.