Science fiction writers have been touting fusion as the utopian future energy production technology for decades. After all, it is how the sun works, and that has been outputting energy for 4.6 billion years already, with about 5 billion more to go before it burns out. But while research has been going on apace to make nuclear fusion energy production a reality, so far nobody has achieved “net energy”, where more power is produced than is used to create the reaction. Now TAE Technologies reckons it will get there soon – and the first commercial installation could be in the UK.

Nuclear fusion could be with us next decade as a solution to the clean energy problem - and in the ... [+]GETTY

“We are the longest standing pure play fusion power company,” says R. David Edelman, Chief Policy & Global Affairs Officer, TAE Technologies. “We were founded in 1998 with one goal in mind - to develop the cleanest, most commercially viable form of fusion energy.” TAE Technologies’ approach is to use boron-11 and hydrogen instead of deuterium-tritium (two isotopes of hydrogen), which is the more common fuel for current fusion reactors, because it is the easiest to fuse.

“One of the challenges that our founders identified was how you turn a reaction like that into a commercially viable power source,” says Edelman. “There are a number of advantages associated with boron-11 that don't exist with some of the other fuels, specifically that the primary fusion reaction doesn't produce a load of neutrons.” Although fusion in general doesn’t produce as many neutrons as nuclear fission, these are still very dangerous particles for the human body. “When you deal with neutrons, you deal with a device that is harder to manage, that might have to be replaced, that might need to be scrubbed out, that is harder to have people operate.”

This was why TAE Technologies chose hydrogen and boron-11 as fuel. “You'd have a machine that would be expensive to build in the first instance, but much cheaper to operate and could have a much longer life,” says Edelman. However, this kind of fusion reactor requires much higher temperatures than deuterium-tritium. To solve this problem, TAE Technologies was spun out of the University of California in Irvine, founded by Dr Norman Rostoker, with the help of Michl Binderbauer, who is now CEO.

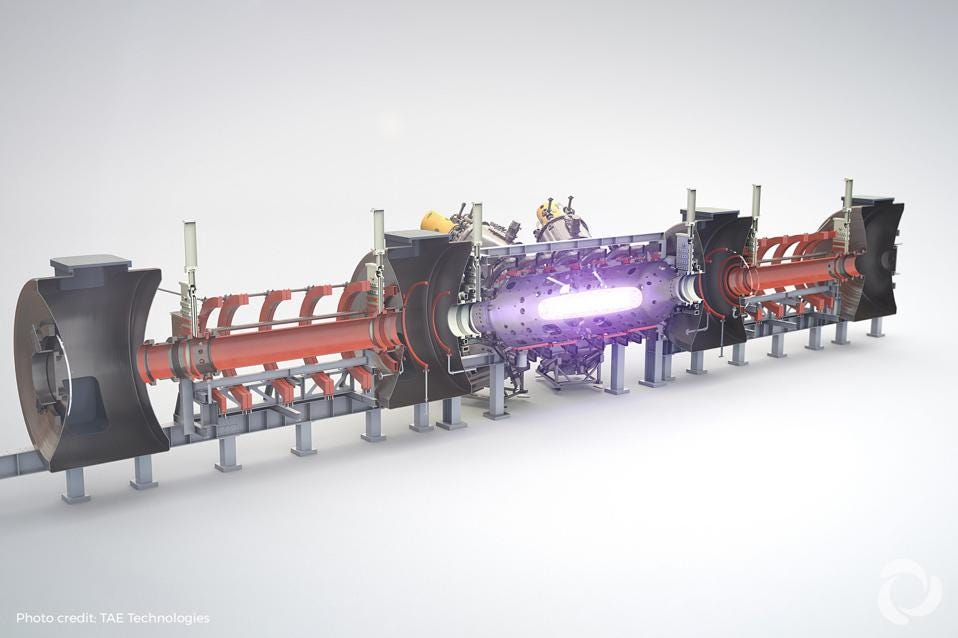

Their insight was to marry traditional plasma physics with particle physics. Particle accelerators are used to drive and sustain the fusion reaction. This also generates a magnetic field, which contains the reaction, in a process called Field Reverse Configuration (FRC). The temperature of fusion means you can’t use any metal as a container – it would melt. Instead, a magnetic bottle is employed. Most fusion reactors employ external magnets. “Getting atoms to fuse is not the hard part,” says Edelman. “We've been doing that for decades. The hard part is keeping that reaction efficient enough to produce more energy out than it takes in. When you have a system like ours that produces its own magnetic field, suddenly you have a shortcut to reducing the amount of power you must put into the device to get exceptional output results.”

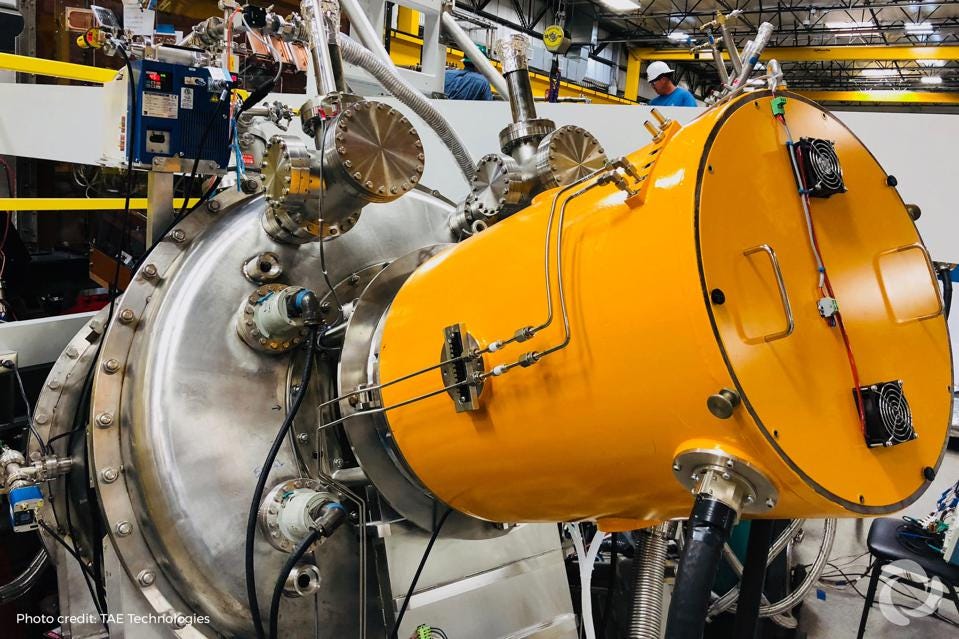

TAE Technologies Norman has achieved operation at 70 million degrees.TAE TECHNOLOGIES

So far, TAE Technologies has built five experimental reactors, all based in California. The company is currently building an experimental machine that can exceed 100 million degrees, which is what is required for “net energy”. This is where the reactor outputs more energy than is being put in. “Our last device, called Norman after our founder, was able to get to 70 million degrees, so we are 70% of the way towards meeting that milestone,” says Edelman. “It was only built to get to 50 million degrees, but we were able to keep pushing, so we're very optimistic. We've proven many of the core conditions that will allow us to reach that net energy milestone in a few years with our next device, which is called Copernicus.”

A key factor in TAE Technologies’ reactor is that its boron-11 fuel is both abundant and cheap. “It is in sand, it is in seawater,” says Edelman. “It can be extracted with great ease, and you need comparatively little of it for a fusion reaction. In fact, to power a fusion power plant at a typical scale – 350 to 500 megawatts output – you would only need a few hundred grams of boron for a year of operation.” Checking with science suppliers, at the time of writing Sigma-Aldrich will sell you 5g of Boron-11B oxide for $218, so the fusion fuel costs will be insignificant.

“That's one of the core advantages because other fuels for fusion, like helium-3 and tritium, are hard to get,” says Edelman. “They involve very complex mining in places that are very hard to mine. Hydrogen, the other element in our reactor, is wildly abundant as well. There is no national monopoly on boron. Many countries have abundant supplies of it.” This contrasts with the radioactive uranium material used by nuclear fission reactors, which is concentrated in certain countries, such as Australia, Kazakhstan, Canada, and Russia. It’s also expensive and dangerous. “We've estimated that if the whole world were running on boron fusion power plants, we'd have 100,000-plus years of terrestrial supply before we would even begin to look elsewhere.”

TAE Technologies uses particle accelerators to generate a self-containing magnetic field for its ... [+]TAE TECHNOLOGIES

This brings us to the role of the UK. Although TAE Technologies has so far built its reactors in California, the company has developed a strong presence in Britain. “We are one of the largest private fusion employers in the UK,” says Edelman. “We have over 200 people based in the West Midlands that are working on what we call our Power Solutions business. These are both the power supplies that help run our fusion machine, but also our efficient power drive trains and other power efficient power storage solutions that are usable right now for electric vehicles, to make them go further on the same battery chemistry and to make them charge faster.”

These are not necessarily direct fusion technologies, but what Edelman calls “fusion adjacent” – production skills that will smooth integration into a commercial ecosystem. The UK expertise TAE Technologies focuses on includes areas like batteries that can be used for utility scale grid storage for intermittent sources such as wind and solar. However, the UK does have strong fusion expertise as well, such as through the Joint European Taurus (JET) in Culham, Oxfordshire and the Spherical Tokomak for Energy Production (STEP) planned for West Burton on Nottinghamshire.

“The professionals in the British system identified early that there was a need for a distinct regime for fusion power plants and that the UK should be the first country in the world to advance it,” says Edelman. “The UK has exceptional talent in this that can lead to cutting edge and world leading fusion commercial work. The United Kingdom has positioned itself at the front of the pack for the world’s first commercial fusion plant.” This includes STEP, which aims for net energy by the 2040s.

Boron-11, the core fuel of TAE Technnologies fusion reaction, is cheap and abundant.GETTY

The readily available supply chain in the UK drives costs down for companies developing fusion in the country and has intellectual property benefits as well. “There's a lot of expensive intellectual property that goes into these devices,” says Edelman. “That means that companies like ours aren't terribly interested in building them in places like China, and instead we're interested in building them in places where we know there's not just the necessary expertise, but also the clear rule of law to protect the core intellectual property that we have.”

This has led TAE Technologies to consider the UK for its first commercial “net energy” fusion reactor, supplying electricity to the grid. “We are looking very seriously to the UK for the first fusion power plant because all the factors we need are there to build at a price that it can start to move the needle for energy independence and net zero,” says Edelman. There are implications that this will be in the West Midlands, where TAE’s other UK interests are. But Edelman remains uncommitted about the location. “Our power supply team is in the West Midlands, but there are a lot of factors that would go into the specific siting of a fusion power plant.”

However, Edelman is more bullish about timeframe – and it will be well ahead of STEP. “We expect to have a first-of-its-kind fusion power plant on the grid early next decade,” he says. “We're not talking 2040, we're talking 2030, which means we must start building that plant in the latter part of this decade, so we need to have a location decided sometime mid this decade. We can then start to scale that towards mass production power plants that can be put into operation at full scale and start to bring down the cost of energy from fusion in the middle of the 2030s. That would be just in time to make a significant impact on climate because if your first fusion power plant isn't in operation till 2045, 2050 is just around the corner.”

“Fusion can offer low impact, zero carbon, effectively limitless energy produced through a triumph of science,” concludes Edelman. “It can do this without the drawbacks of most other sources of energy. You can put fusion power plants where the power is consumed. You don't need to put a fusion power plant offshore, or where it's sunny all the time, or on top of a deposit of minerals. It can be put safely inside population centers, which can save the 20% of generated electricity that is lost in long distance transmission. Our kind of fusion power plant can be very compact - just a few hectares. It doesn't need a large exclusion zone and the risks associated with it are no different than those of any industrial facility. Fusion can make up the yawning gap between the energy we know we need by 2050 and the energy that we know can be produced in low and no carbon ways by 2050.” And that gap could start to narrow in the UK sometime next decade.