Researchers have developed a new thermoelectric generator (TEG) that can continuously generate electricity using heat from the sun and a radiative element that releases heat into the air. Because it works during the day or night and in cloudy conditions, the new self-powered TEG could provide a reliable power source for small electronic devices such as outdoor sensors.

"Traditional power sources like batteries are limited in capacity and require regular replacement or recharging, which can be inconvenient and unsustainable," said research team leader Jing Liu from Jimei University in China. "Our new TEG design could offer a sustainable and continuous energy solution for small devices, addressing the constraints of traditional power sources like batteries."

TEGs are solid state devices that use temperature differences to generate electricity without any moving parts. In the journal Optics Express, Liu and a multi-institutional team of researchers describe and demonstrate a new TEG that can simultaneously generate the heat and cold necessary to create a temperature difference large enough to generate electricity even when the sun isn't out. The passive power source is made of components that can easily be manufactured.

"The unique design of our self-powered thermoelectric generator allows it to work continuously, no matter the weather," said Liu. "With further development, our TEG has the potential to impact a wide range of applications, from remote sensors to wearable electronics, promoting a more sustainable and eco-friendly approach to powering our daily lives."

Boosting TEG performance

When a thermoelectric material experiences a temperature gradient, electrons will flow from the hot portion to the cold portion, generating an electric current. Although TEGs based on this phenomenon exist, they tend to produce unstable temperature differences and don't generate enough electricity to be useful.

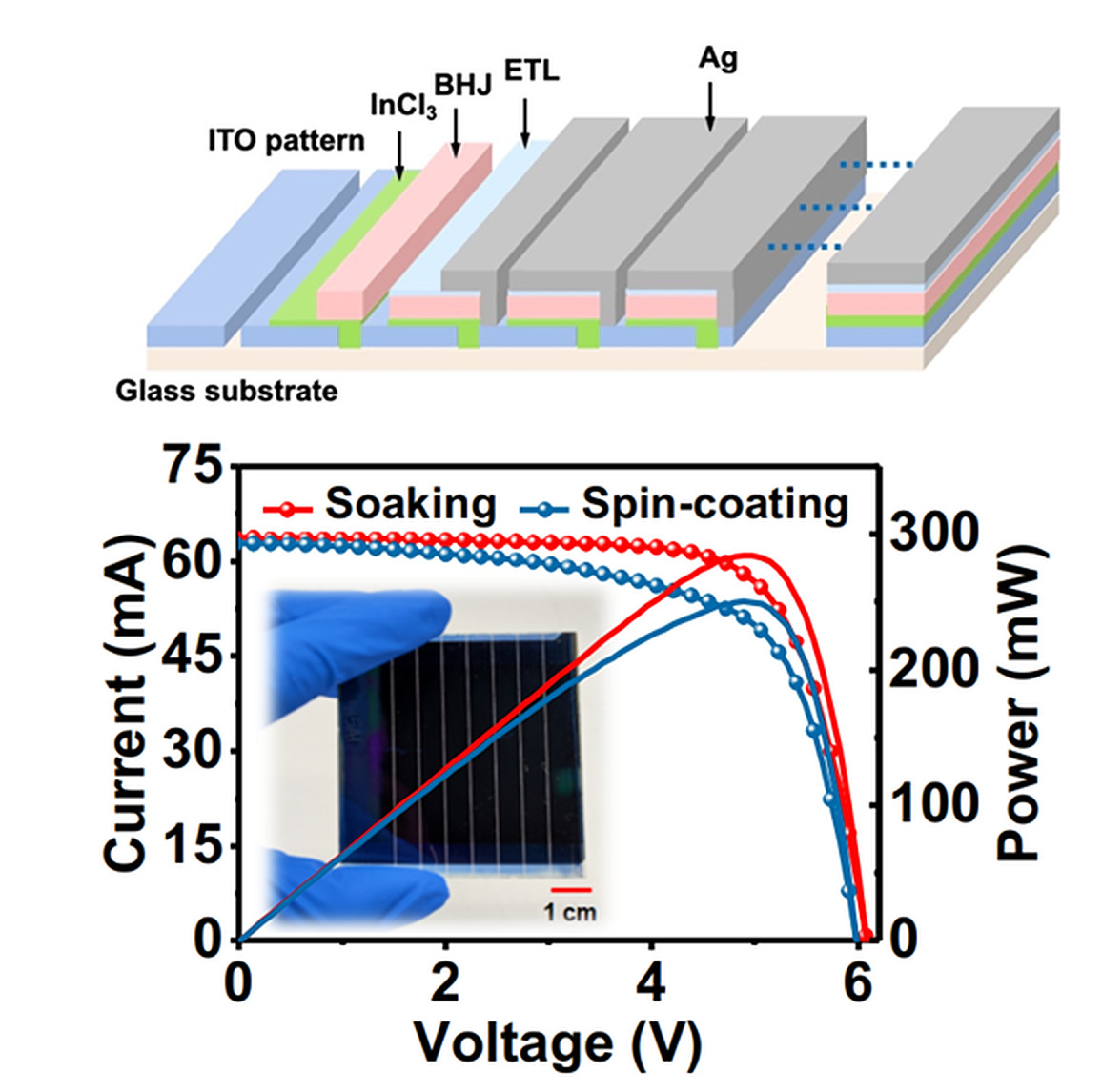

To address these limitations, the researchers developed a new type of TEG. It uses a component called an ultra-broadband solar absorber (UBSA) to capture sunlight, which heats one side of the generator. Simultaneously, another component called a planar radiative cooling emitter (RCE) cools down the other side by releasing heat. Both the UBSA and RCE can be applied to a flexible substrate, which could be useful for powering wearable devices, for example.

Because the heating power of the UBSA is significantly greater than the cooling power of the RCE under normal sunlight intensity, the researchers placed the RCE on top of an UBSA with a larger area. When sunlight hits the entire device, the unshaded parts of UBSA absorb the sun's energy to heat up while the RCE on top begins to cool. The combination of heating and cooling creates a temperature difference that is converted into electricity.

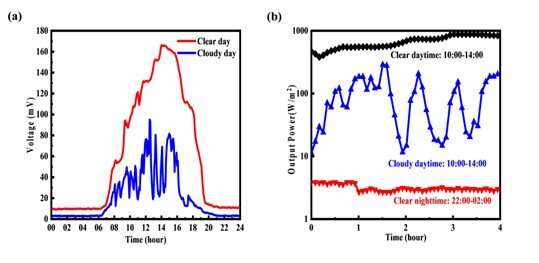

At night or on cloudy days, the temperature difference is significantly reduced due to the absence of direct sunlight. However, there is still some temperature difference that can be utilized to generate electricity, albeit at a lower efficiency compared to a sunny day.

Generating power at night

To test the device, the researchers conducted outdoor experiments under different weather conditions. They monitored the voltage output of the device and found that it could generate electricity continuously throughout the day and night and during cloudy daylight conditions. The device achieved a peak voltage output of 166.2 mV during clear daytime conditions, enough to power a small sensor or device. During clear nighttime and cloudy daytime conditions, it generated 14.7 mV and 95 mV, respectively.

"Our innovative method for combining solar heating with radiative cooling allows the TEG to generate electricity that is uninterrupted," said research team member Haoyuan Cai. "This could improve access to critical services, particularly in remote or underdeveloped areas where traditional power sources are not available."

The researchers are now working to further optimize the device's efficiency, durability and scalability and plan to test its long-term stability and reliability under various conditions. They also want to explore the potential for mass production at a reasonable cost and make improvements in the device's performance and adaptability to different applications.