NEO Battery Materials, a developer of silicon anode materials for lithium-ion batteries, reported that it has achieved uniform nanocoating capability in its manufacturing process. The new uniform nanocoating allows NEO’s proprietary silicon anode materials, NBMSiDE, to extend EV driving ranges and suport faster battery charging.

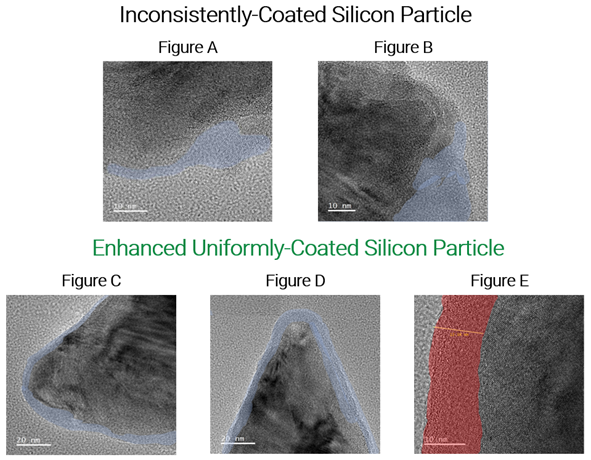

NEO has achieved the nanocoating conditions to produce uniformly-coated silicon particles consistently. As a result, uniform nanocoating layers will be an additional advantage to enhance the current performance achieved by NBMSiDE. Previously, non-uniform coatings often resulted in substandard capacity retention of NBMSiDE due to mechanical breakdown (refer to Figures A and B).

However, the ability for uniform nanocoating will ensure robust capacity retention and enable coating thickness control during commercial-level testing. Figures C to E show that the enhanced capability is agnostic to the silicon’s shape and structure, making possible uniform coatings on both spherical and edged particles, NEO said.

Achieving uniform coating layers on the nano-scale is an exceptionally difficult task for a company of any size that handles chemical products. Especially for NEO, our metal silicon inputs take on a plate-shaped structure, which adds to the technical hurdle of enabling uniform coatings. However, by achieving this uniform coating capability through an additional solution process, we have made a remarkable accomplishment and have amassed great interest from 3rd party industry experts and players.

—Dr S. G. Kim, CTO of NEO

Over the past 2 years, the company has developed a novel manufacturing approach that combines the mixing, grinding, and nanocoating process into a one-step system. NEO says that this will allow it to supply silicon anodes that are 70% cheaper compared to current competitors’ technologies. The company is also underway filing additional patents related to the technology and additive materials for the uniform coating solution process.