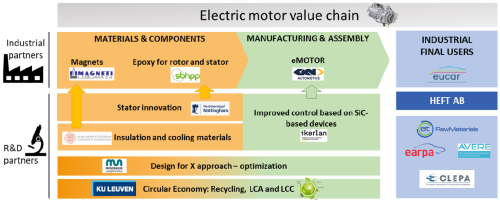

HEFT considers that an energy-efficient rare-earth synchronous motor is the best option for next-generation high-power primary axle traction EVs. The project proposes a set of innovation challenges on electric synchronous motor configuration based on SiC inverters (direct cooling of rotor and stator, advance insulation for high voltage, multibarrier rotor topology, wave windings) and advanced materials (advanced GBD magnets, epoxy for magnet fixation, composite for motor housing, insulation resin).

The innovations are intended to result in a high-efficient and low-cost solution that will be validated on 2 motor topologies, which will be compared to two main reference automotive IPM commercial motors in Europe (VW ID.3 and FIAT500) with the expectation of: >800V, 20% reduction losses, >7 KW/kg and 42kW/l power density, 28% cheaper, 50-66% material savings, including 60% reduction of REE (rare earth elements) content and >80% REE recyclability rate.

As this solution is still dependent on REE from China, HEFT will be aligned with the ERMA action plan towards a circular economy market of rare earth permanent magnets and suggests: one alternative magnet route (Ce based) and two REE recycled routes together with policies promotion towards the foundation of a European rare earths industry, capable of delivering 20% of EU demand by 2030.

HEFT plans 8 work packages (WPs) to implement these concepts, where 5 research partners will be essential for developing innovative ideas around the design-to-x approach, while strong companies (GKN, MAGNETI, VYNCOLIT) will ensure that HEFT results have a clear market orientation and fulfil the industry needs.

HEFT plans to organize OEM workshops to ensure wide adoption of HEFT solutions, but also with policymakers to promote regulations towards the EU circular market that would help maintaining the leadership of EU companies, while increasing their competitiveness and job opportunities linked to the new circular business models.

The first consortium meeting is being held in May.