Dutch scientists have used atomic layer deposition to build an organic solar cell with a tin oxide electron transport layer. This improved electron mobility and transparency, resulting in a record fill factor.

A group of scientists at the University of Groningen in the Netherlands has fabricated an organic solar cell based on an electron transport layer (ETL) made of tin oxide (SnO2) that reportedly enables the device to achieve a remarkable fill factor of 79%.

Currently, organic solar cells are lagging behind their inorganic competitors as they achieve less current production, have higher open-circuit voltage losses, and feature a lower fill factor, which in these PV devices usually does not exceed 80%.

The researchers explained that SnO2 is a promising alternative to zinc oxide (ZnO) for ETLs used in organic PV, as its energy levels are suitable for an efficient collection of electrons. “When compared with ZnO, SnO2 offers higher electron mobilities and a superior transparency to the visible and UV light,” they stated, noting that ZnO, however, is more photoreactive than SnO2.

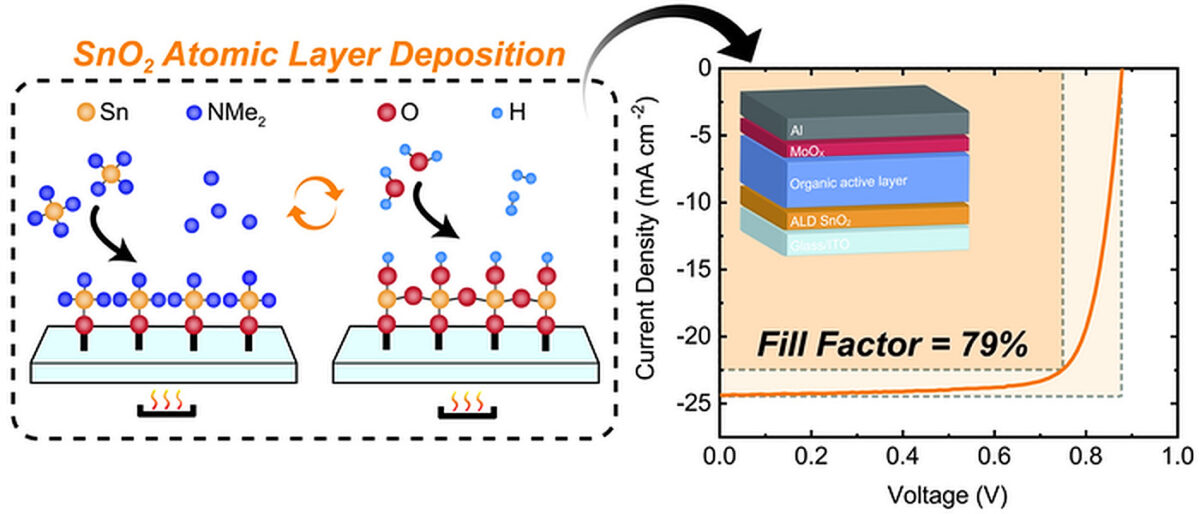

The Dutch group utilized atomic layer deposition (ALD) to deposit the SnO2 thin film, which it said avoids adjusting its surface via additional fabrication steps.

“Furthermore, compact layers can be deposited at relatively low temperature (below 100 C), with the possibility of fine-tuning both the electrical and optical properties of the material,” it further explained, adding that the deposition process shows a tradeoff between the transparency of the material, which is higher at lower temperatures, and the electrical conductivity, which is improved when the deposition temperature is raised.

The academics built the cell with a substrate made of glass and indium tin oxide (ITO), the ETL based on SnO2, an organic active layer, a molybdenum oxide (MoOx) layer, and an aluminum (Al) metal contact. The organic absorber was made of two different donor–acceptor blends acting as active layers. The first is composed of two polymers known as TPD-3F and IT-4F, and the other of two polymers known as PM6 and L8-BO.

The solar cell built with PM6 and L8-BO achieved the best performance among all tested devices by reaching a power conversion efficiency of 17.26%, an open-circuit voltage of 0.872 V, a short-circuit current of 25.55 mA cm−2, and a fill factor of 79.0%. For comparison, a reference cell built with an ETL based on ZnO reached an efficiency of 16.03%, an open-circuit voltage of 0.878 V, a short-circuit current of 25.10 mA cm−2, and a fill factor of 74.0%.

“Both these values are currently the highest values reported for OSCs with inverted structure and SnO2 as ETL,” the scientists said referring to the cell efficiency and fill factor, respectively.

They introduced the cell in the paper “Outstanding Fill Factor in Inverted Organic Solar Cells with SnO2 by Atomic Layer Deposition,” which was recently published in Advanced Materials.

“Our aim was to make organic solar cells more efficient and to use methods that are scalable,’ says Garcia Romero. The efficiency is close to the current record for organic solar cells, which stands around 19%,” the research team concluded.