Vallourec qualifies VAM 21 connections for temperatures up to 350 C (source: Vallourec)

Vallourec qualifies VAM 21 connections for temperatures up to 350 C (source: Vallourec)“When you double the temperature, say from 200 °C to 400 °C, you multiply the energy generated up to 10 times. There is huge potential for the industry to design and validate solutions to build systems at those levels,” stated François Penven, Marketing & Development Manager for Geothermal Applications at Vallourec.

Vallourec had recently made an investment in GreenFire Energy, a closed-loop geothermal energy technology startup.

The challenges of high-temperature projects

Oil and gas wells usually require connections to be qualified at 180 °C. In geothermal wells, pipes and connections are exposed to much higher temperatures, reaching anywhere from 200 °C to 350 °C. Furthermore, the number of geothermal wells operating at higher temperatures is expected to increase in popular geothermal regions such as Indonesia, the Philippines, East Africa, Iceland, and California.

When exposed to higher temperatures, pipes and connection are subjected to a higher degree of material dilatation. For instance, the API-5CT Range 3 pipe, which is around 12.5 meters long, gains around 60 mm of length when heated up to 350 °C. In a 2000-meter deep well, the dilatation can account for about 9 meters of additional length. Since the casing is cemented, the end cannot move meaning that the strain is shared along the string.

While VAM® connections have gone beyond 180 °C in the past, Vallourec had never ventured further than the 240°C experienced in high pressure/high temperature O&G well applications. To ensure successful qualification, Vallourec’s teams adapted existing models and developed new testing tools.

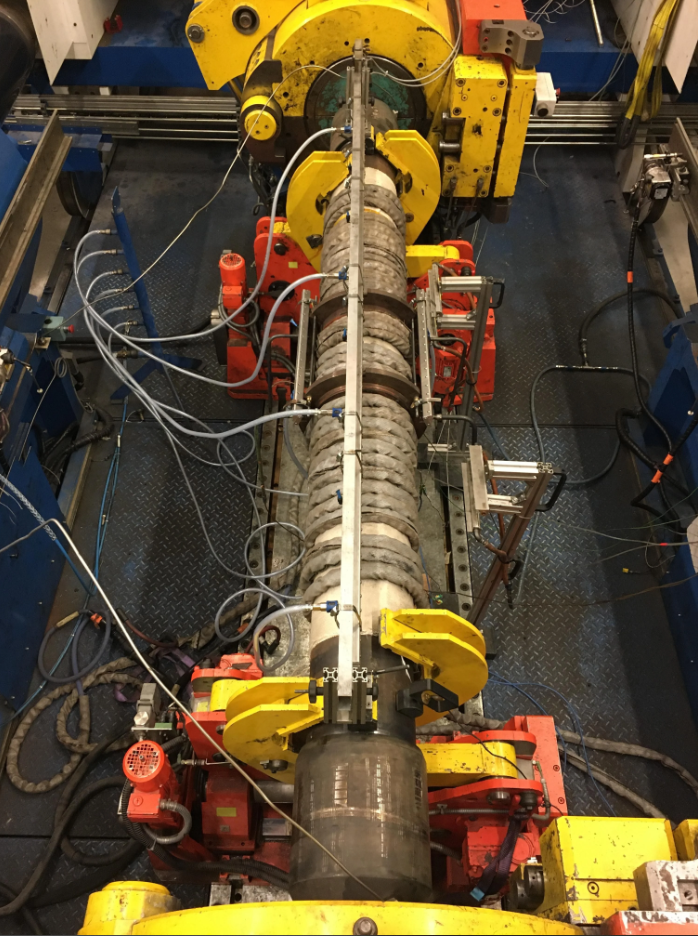

The testing setup of Vallourec (source: Vallourec)

Testing geothermal connections to high-temperature standards

To accommodate high-temperature conditions, the Thermal Well Casing Connection Evaluation Protocol (TWCCEP) standards require connections to be tested and qualified at 350 °C. To make the test, Vallourec R&D developed new measuring devices by adapting existing equipment to account for strain.

“Testing adjustments also included the development of new make & break qualifications”, explained Pierre Mauger, R&D Engineer at Vallourec. “This included using a lubricant that can withstand the higher temperatures”.

“The existing testing frames we have were programmed to test products under stress, not strain. For geothermal, it’s important to test under strain, which occurs when the pipes expand within the well’s cementation. It’s also known as dilatation, and results in great compression loads on connections,” added Mauger.

These developments have provided Vallourec with valuable insights and expertise in geothermal qualification that set it apart from other players in the market, providing a competitive edge.

Connections that stand the test of time, temperature, and compression

The TWCCEP qualification ensures that VAM® connections can absorb high levels of strain and induced compression loads without failure or leakage. Testing connections at high temperatures contributes to both extended well life and improved well performance.

“VAM® 21 is designed to be 100% resistant to compression, which is different to previous pipe connection versions,” François says. “In other words, the connection is as strong as the pipe. In its DNA, the connection’s design is resistant to both compression and temperature.” VAM® 21 already has a long history on the market, with more than a decade of use in other high pressure and high temperature applications. This history demonstrates its reliability and robustness.

With its range of products, extensive knowledge in the field and new testing protocol, Vallourec is well-equipped to aid customers in pursuing their geothermal ambitions across all hotspots worldwide. The company is also researching even higher temperatures, up to 450° C, to meet future demands of geothermal projects across the world.