The Renewable Energy Test Center (RETC) raised the issue of ultraviolet-induced degradation of the trending technology in its PV Module Index 2022.

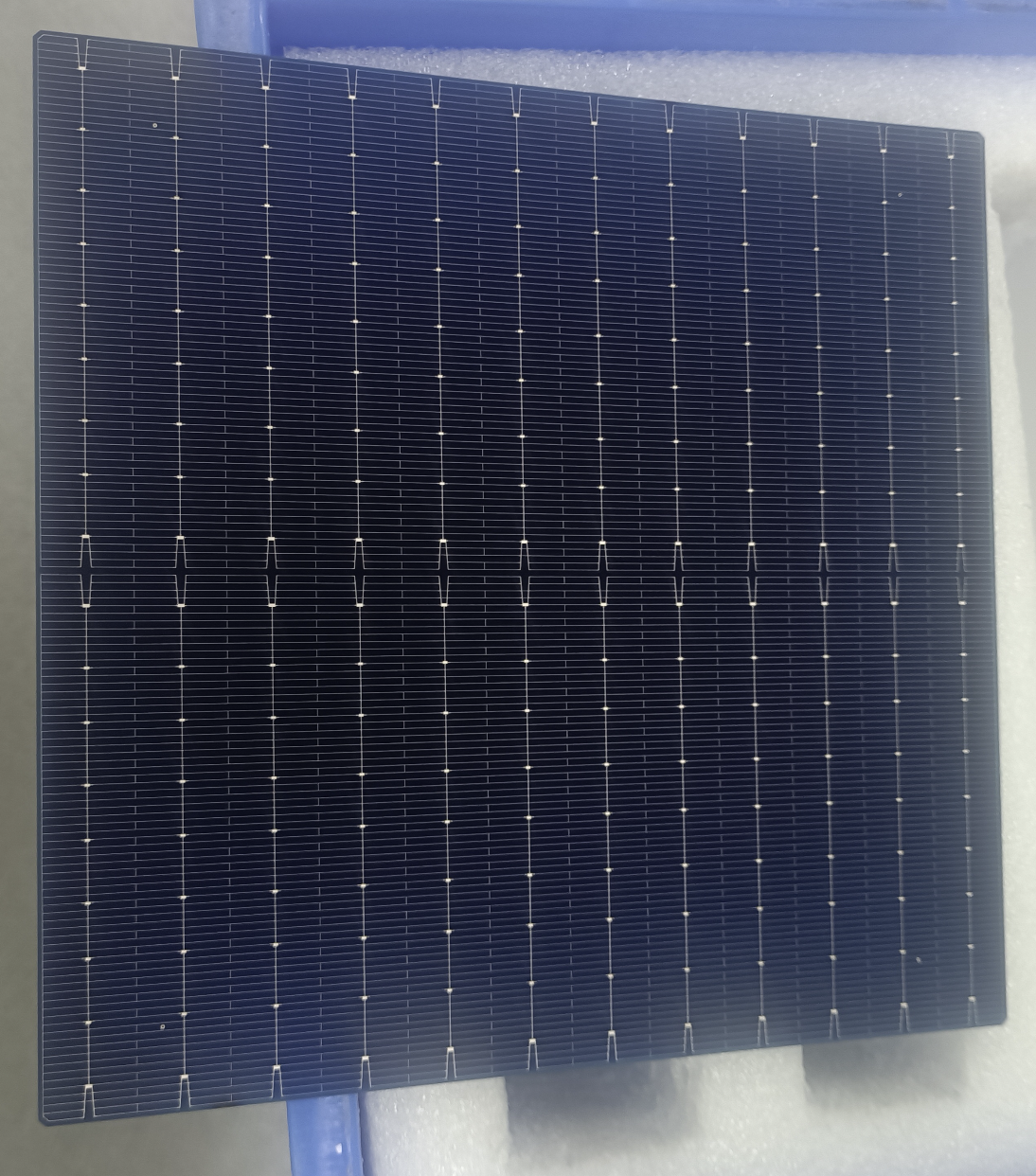

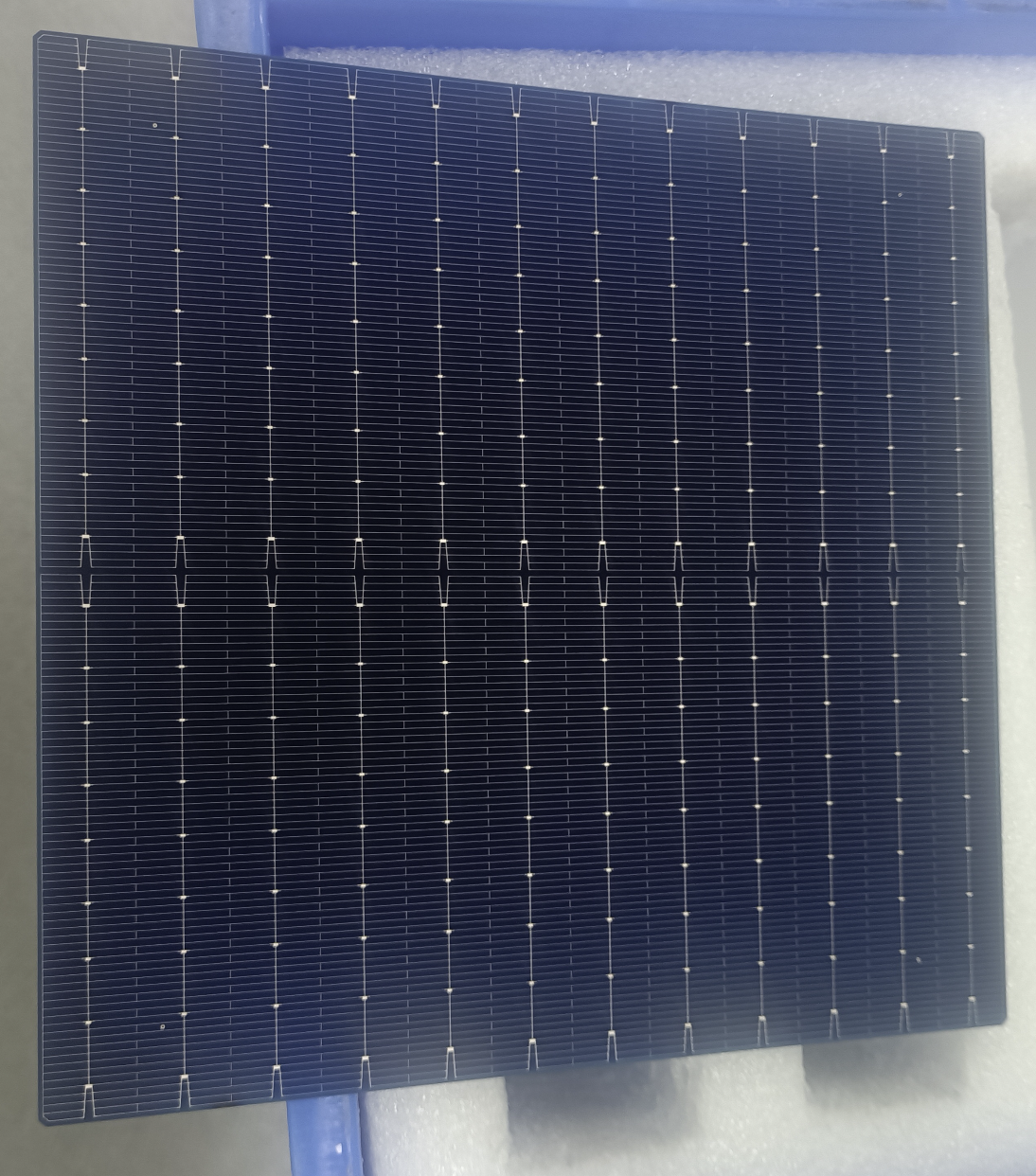

Image: Nantong University

Each year, Fremont, California’s Renewable Energy Test Center (RETC) releases its PV Module Index, tracking the latest trends in solar module quality, performance, reliability, and emergent technologies.

The latest annual report, PV Module Index 2022 opens with remarks about the rise of TOPCon solar modules, a technology increasingly being adopted by major panel suppliers.

TOPCon was first demonstrated at Germany’s Fraunhofer Institute for Solar Energy Systems in 2013 and is now gaining market traction and acceptance.

The technology is comprised of n-type PV cells with passivating contacts. The modules have strong surface passivation and effective carrier transport, both of which contribute to a strong open-circuit voltage and high efficiency. The shift to TOPCon comes as p-type passivated emitter and rear-contact cell (PERC) modules begin to reach their theoretical efficiency limits.

RETC said this boost in efficiency has made TOPCon “the buzziest word in solar.”

The report noted that while Longi is “betting big” on p-type TOPCon, many other leading module companies, like JinkoSolar, Jollywood, JA Solar and Trina Solar are making significant investments in modules with n-type TOPCon cell designs.

“Via higher open-circuit voltage values, you can achieve higher efficiencies and power ratings. In and of itself, that is likely going to move manufacturers to n-type TOPCon cell designs, as soon as they can get there,” said Kenneth Sauer, principal engineer, VDE Americas.

RETC said due to manufacturing complexities, high-efficiency n-type cells using heterojunction technology (HJT) and interdigitated back contact (IBC) cells are relatively expensive to produce and remain a niche part of the market. By comparison, n-type TOPCon cell production is very similar to the PERC manufacturing process, making for an easier transition from existing manufacturing lines.

“Though today’s n-type TOPCon modules cost slightly more to produce on a per-watt basis than p-type mono PERC modules, the efficiency gains result in a lower levelized cost of energy (LCOE) in large-scale field deployments. Best of all, leading experts expect n-type TOPCon to benefit from an accelerated learning curve,” said the report.

However, as with any emergent technology, the report notes that moving towards TOPCon may carry some risk. While n-type TOPCon PV cells have proven resilient to light-induced degradation and light and elevated temperature-induced degradation, some evidence exists of susceptibility to ultraviolet-induced degradation (UVID), which could chip away at module longevity.

Researchers at the SLAC National Accelerator Laboratory and the National Renewable Energy Laboratory (NREL) have documented front- and back-side power loss from these technologies. The data does not point to a single degradation mechanism but suggest that different cell designs degrade via different pathways, said the report.

“We’re not trying to sound an alarm for no reason,” said Cherif Kedir, chief executive officer at RETC. “We just want to test the potential for UV degradation to educate ourselves and the industry. If there’s no problem, we can all move forward with our lives.”

Kedir recommends module makers conduct accelerated UVID testing as part of a technical due diligence survey. If cell passivation layers are improperly tuned, they can break down under this exposure. He recommends evaluating each new cell design on a case-by-case basis.

“If there is a problem, we will publish a report so that the industry can get out in front of the issue,” he said.