Two Norwegian companies are designing floating concentrating photovoltaic thermal technology that can produce both electricity and heat. It is intended for use in carbon capture projects and to be supported by an industrial heat pump system.

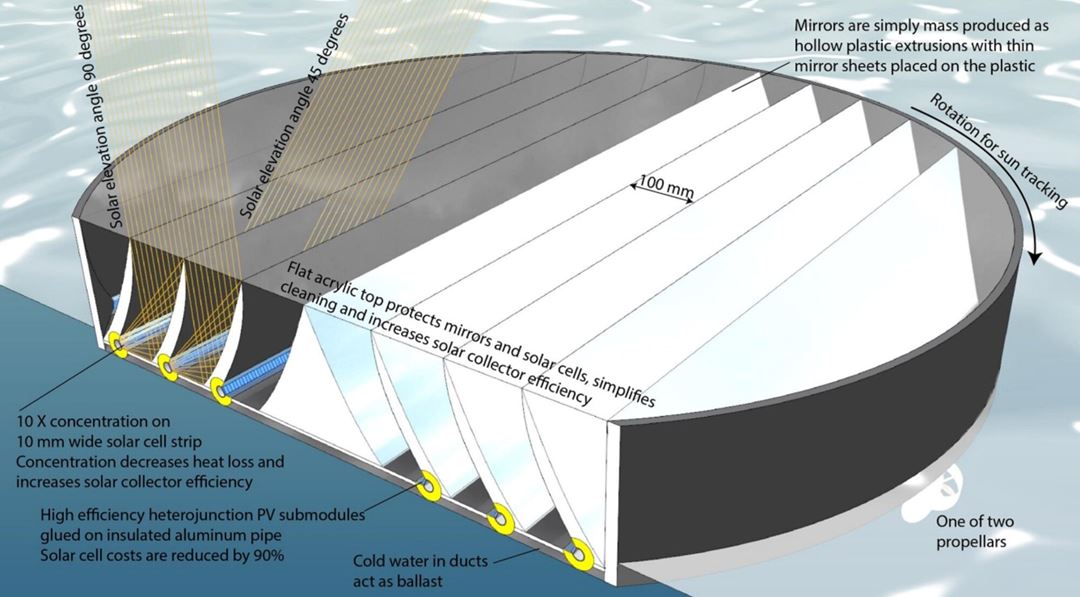

Diagram illustrating the concept of a floating solar energy plant that generates both electricity and heat

Image: Sintef

Norway-based research firm Sintef and Norwegian floating PV specialist Svalin Solar are currently developing a floating concentrating photovoltaic thermal (CPVT) receiver that is intended for use in carbon capture facilities.

“The energy requirement needed for CO2 stripping is perhaps the most dominant factor governing solvent-based post-combustion capture technology,” Sintef's Senior Business Developer, Martin Bellmann, told pv magazine. “In essence, any technology that significantly reduces the so-called reboiler duty – energy consumption for CO2 striping – is highly sought after.”

The two companies described the new technology as a solar-assisted carbon capture system that either entirely or in part generates the thermal energy needed for gas separation.

“The proposed CPVT design is a single-axis tracking system of the type ‘linear through’, where the rows of curved mirrors are mechanically rotated so that the length-wise direction of the mirrors is always parallel to the incidental sunlight and follows the daily motion of the sun,” Bellmann added. “Concentration ratios of around 10 suns can be achieved.”

The CPVT receiver is based on a pipe with solar cell stripes attached to it. The small area of the CPVT receiver allows for the use of high-efficiency PV cells. “Although these PV cells are more expensive, the cost can be offset by the reduced area required,” Bellmann explained. “Conventional crystalline silicon and multi-junction cells are to be considered. Then, the price-to-performance ratio will be assessed once the prototype is up and running and we have collected sufficient enough data from the test trials.”

According to Sintef, the efficient thermal management of the CPVT receiver is achieved by a heat transfer fluid circulating through the pipes. Cold fluid enters the pipe network at the inlet collecting the heat from the receiver and keeping the PV cells at low temperature. The collected heat is then transferred to a high-temperature heat pump (HTHP), which acts as an auxiliary thermal energy booster that upgrades waste heat and low-temperature heat from the receiver for steam production in the Carbon Capture Storage (CCS) process.

The electric power produced by the PV cells can either be supplied to the grid or used directly to power the HTHP or other auxiliary processes in the CCS process.

Sintef is currently working on the design and upscaling of the Svalin Solar plant design and plans to buy the components and set up a pilot facility in the summer of 2024. “Initially, the plant will be tested on dry land as part of an existing carbon capture facility that Sintef operates at Tiller, just outside Trondheim,” Bellmann stated. “To achieve a cost-efficient CPVT system design, it is crucial to understand if the annual energy production, both thermal and electric, can compensate for added costs for installation, tracking and maintenance.”

The demonstrator will be part of the EU-funded project “Transformation of energy intensive process industries through integration of energy, process, and feedstock flexibility” (TRINEFLEX), which has a total budget of €19.3 million ($21.2 million) and includes 28 partners.

Other researchers at Sintef recently developed a floating structure for offshore PV, a high-temperature industrial heat pump that can work with pure water as its work medium, and a floating solar platform for use in aquaculture projects.