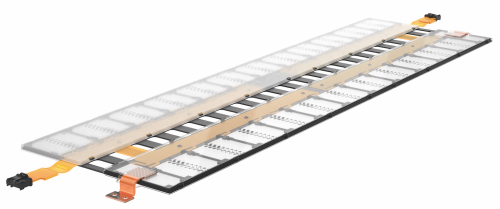

Cell contact systems consist of a plastic carrier frame that accommodates the cell connectors and ensures installability in all tolerance positions. The required voltage and temperature sensors are already included, while the electronic cell supervision circuit can be integrated by the customer. Approved or newly developed automotive connector systems are used at the interfaces (Plug & Play).

In securing this contract, the E-Mobility business unit has won another high-volume series production order for battery components.

Cell contact systems form an integral part of ElringKlinger's broad product portfolio for the next generation of mobility and have been in series production for more than ten years. They are precisely tailored to customer requirements and are fitted directly onto the cell combination. In addition to performing the functional tasks of voltage tapping, they also include voltage and temperature sensors, thus boasting a high degree of integration.

The machinery used in the series production of cell contact systems is fully automated and all processes are set up to meet the latest standards. The European start of production (SOP) for this order is scheduled for 2025 in Neuffen, Baden-Württemberg.

This is to be followed by production and delivery for the Asian market. In the run-up to SOP, ElringKlinger will invest an amount in the double-digit million euro range in new production machinery and infrastructure measures.