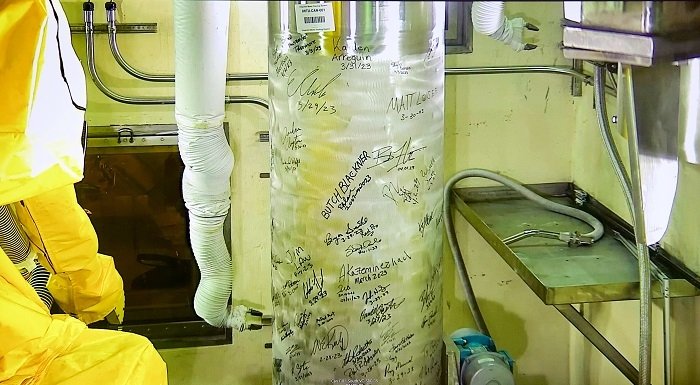

DOE-EM officials, IWTU employees, and others signed the first stainless steel canister prior to crews filling it with sodium-bearing waste and simulant. Once filled, that canister and 15 others were placed in a concrete vault for storage. (Photo: DOE)

Since the launch of operations just over a month ago, the Integrated Waste Treatment Unit (IWTU) at Idaho National Laboratory has increased sodium-bearing waste treatment fivefold. This activity is a vital step in removing the remaining liquid waste from nearby underground tanks at the site and protecting the underlying Snake River Plain Aquifer.

To date, according to the Department of Energy, the facility has converted more than 8,550 gallons of liquid tank waste to a more stable, granular solid.

Works starts: On April 11, The IWTU began treating a blend comprising 10 percent sodium-bearing waste and 90 percent nonradioactive simulated waste, or simulant, which was used for IWTU testing from 2012 to 2023.

IWTU crews have since increased the treatment blend to 50 percent waste and 50 percent simulant before it eventually becomes 100 percent sodium-bearing waste based on the plant’s operating conditions.

Following treatment, the granulated waste is stored in stainless steel canisters—more than 40 have been filled to date—and placed within concrete vaults, each holding 16 canisters.

All IWTU monitoring data is shared with the Idaho Department of Environmental Quality as part of the facility’s operating permit requirements. In the future, IWTU crews will initiate a system performance test to demonstrate compliance with established performance standards and determine adequate operating conditions under the permit.

History: Workers constructed the IWTU from 2007 to 2011 to convert 900,000 gallons of radioactive liquid waste to a granular solid resembling coarse sand using steam-reforming technology. From 2012 to 2023, IWTU underwent testing with nonradioactive simulant. The DOE’s Office of Environmental Management completed subsequent modifications to the facility’s primary reaction vessel, off-gas treatment vessel, process filters, and canister fill cells to address technical challenges.

The hundreds of thousands of gallons of liquid waste were generated during decontamination activities that followed historic spent nuclear fuel reprocessing at the Idaho Nuclear Technology and Engineering Center, an activity that ended at the site in 1992.

The treated waste will remain on-site until a permanent disposal site becomes available.