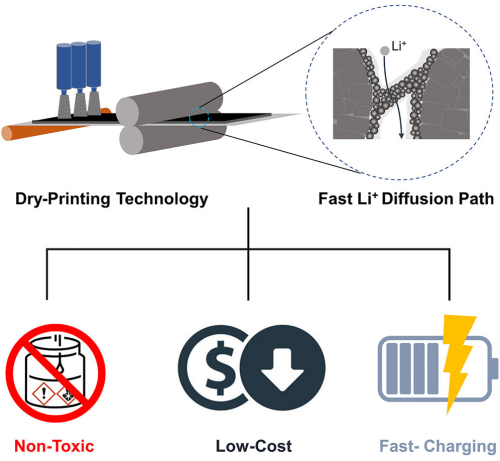

In an open-access paper in the journal Joule, the group reported on a dry-print (DP) manufacturing process that avoids the toxic solvents and the long drying times needed when manufacturing electrodes with slurries and conventional production methods.

The lower tortuosity achieved by the open pores in the dry-printed (DP) electrode allows for a shorter Li+ diffusion pathway, which leads to better rate performance. The DP pouch cells exhibit higher capacity retention of 78% and 69% at 3C and 4C, respectively, compared with 67% and 52% for the slurry cast (SL) cells at the same rates. Moreover, the coating layer on the surface of active materials prevents the excess side reaction between active materials and electrolytes, which prolongs the cycle life of the DP cells. This manufacturing process is a roll-to-roll system with immense potential to be scaled up, providing a more efficient and economical way for battery manufacturing.

—Liu et al.

Wang, the WPI William B. Smith Dean’s Professor in the Department of Mechanical and Materials Engineering, said the new process could be scaled up and reduce electrode manufacturing costs by up to 15%, while also producing electrodes that can charge faster than conventionally produced electrodes.

Current lithium-ion batteries charge too slowly, and manufacturers typically use flammable, toxic, and expensive solvents that increase the time and cost of production. Our solvent-free manufacturing process addresses those disadvantages by producing electrodes that charge to 78 percent of capacity in 20 minutes, all without the need for solvents, slurries, and long production times.

—Yan Wang

Commercial lithium-ion battery electrodes are typically made by mixing active materials, conductive additives, polymers, and organic solvents to create a slurry that is pasted onto a metal substrate, dried in an oven, and cut into pieces for use in batteries. The solvents are recovered through distillation.

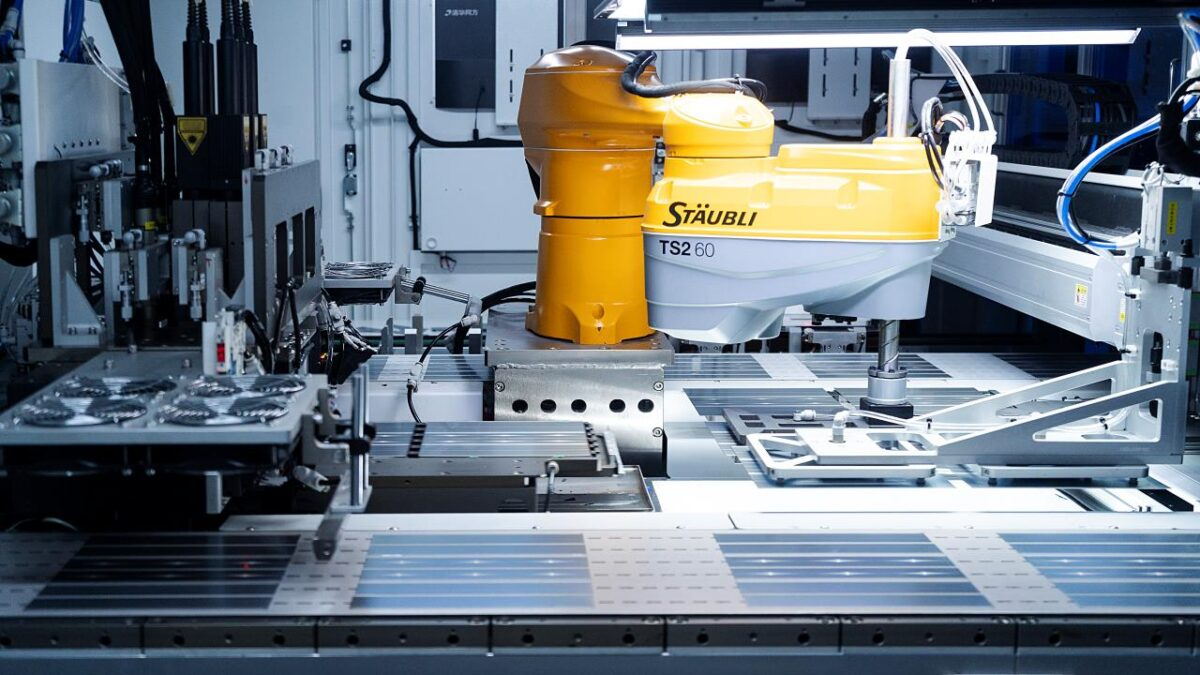

The researchers’ process, in contrast, involved mixing together dry powders that were electrically charged so they would adhere when sprayed onto a metal substrate. The dry-coated electrodes were then heated and compressed with rollers. Skipping the conventional drying and solvent-recovery process cut battery manufacturing energy use by an estimated 47%, the researchers reported.

WPI has filed a patent application on the manufacturing technology developed by Wang’s team. In addition, Wang and one of his collaborators, Heng Pan of Texas A&M University, co-founded AM Batteries Inc., a venture-backed company that is working with Amperex Technology Limited (ATL) and other companies to scale up solvent-free electrode manufacturing.