Will H2 still be a practical option with options growing for battery electric big rigs in the United States?

Last year, the Megawatt Charging Standard (MCS) was formalized, making it possible to roll out charging stations better suited to the needs of big rigs, making some wonder if hydrogen fuel trucks will even be necessary.

Some EV experts have predicted that the MCS will mean that battery electrics will be all that is needed.

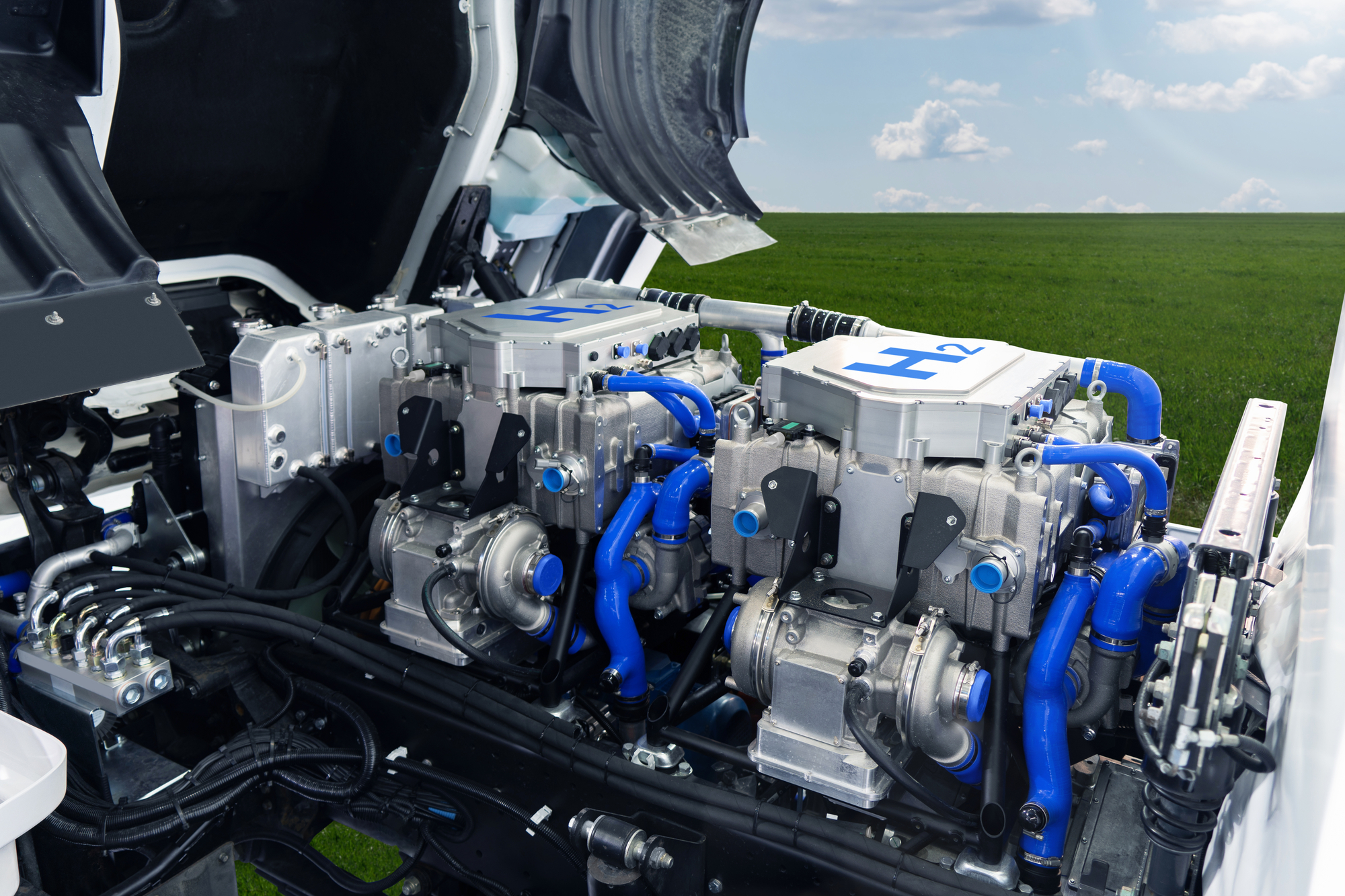

That said, even after the MCS was formalized, major companies have continued their focus on hydrogen fuel trucks and on their potential to help decarbonize the transport industry. While passenger cars have heavily leaned toward battery electrics, the same has not occurred in trucking. What has yet to be seen is whether the enthusiasm for H2 will continue in big rigs, or if the rollout of an electric charging infrastructure will make companies change gears.

Of course, what must also be determined is if big rig electric vehicles (EVs) will also be able to overcome the other challenges they face when compared to the use of H2 as a replacement for fossil fuels. After all, charging time was only one of several obstacles EVs would need to overcome in order to keep up with what H2 has to offer this industry.

Credit: Photo by depositphotos.com

Hydrogen fuel trucks can still play a central and key role in the decarbonization of transport.

Charging time is certainly a consideration. Before megawatt charging stations are installed, it would take hours to recharge a big rig, whereas H2 would need only about the same amount of refueling time as gasoline or diesel. With the MCS, that recharging time could be reduced to what is being called a “reasonable” charging time for classes 6, 7 and 8 commercial vehicles.

Still, batteries have yet to compete with the range of fuel cells, and H2 has a notable weight advantage in current technologies. This is not to mention the massive amounts of lithium and other rare, expensive, difficult to mine, and environmentally unfriendly materials required to make the massive batteries that would be required to power those vehicles.

Comparison of BEVs and FCEVs:

Efficiency:

BEVs: Higher efficiency due to fewer conversion processes, resulting in fewer energy losses.

FCEVs: Lower efficiency as conversion processes result in energy losses of about half.

Payload:

BEVs: Lower payload capacity, weighing up to 5,775 kg more than FCEVs for a range of 800 km (gap reduced for shorter ranges).

FCEVs: Higher payload capacity, allowing for the transportation of heavier loads.

Range:

BEVs: Limited range of up to 400 km.

FCEVs: Longer range of up to 1000 km with liquid hydrogen storage.

Lifespan:

BEVs: Estimated battery lifespan of 1,000 cycles.

FCEVs: Longer fuel cell lifetime of 10,000 hours (or up to 30,000 hours with some manufacturers).

Pros of Hydrogen Fuel Cell Trucks:

Longer range time than BEVs.

Cleaner alternative to traditional diesel trucks, emitting only water as a byproduct.

Greater payload capacity for transporting heavier loads.

Cons of Hydrogen Fuel Cell Trucks:

Less efficient than BEVs, requiring more energy to travel the same distance.

Lack of infrastructure for hydrogen refueling stations.

Higher cost of producing hydrogen fuel cells, making FCEVs a more expensive option – see below for semi cost comparison.

Credit: Photo by depositphotos.com

Pros of Battery-Powered Trucks:

Higher efficiency ratings than FCEVs, making them an environmentally friendly option.

Decreasing battery costs, making BEVs more affordable over time.

Wider availability of charging stations compared to hydrogen refueling stations.

Cons of Battery-Powered Trucks:

Limited driving range before requiring a recharge, impacting delivery schedules.

Lower payload capacity than FCEVs, making them less ideal for transporting heavy loads.

Significant cost of replacing batteries, adding to the overall lifetime cost of the vehicle.

A Closer Look at Cost

Cost of these new trucks are running from $188,000 to $250,000 for the battery powered truck and starting at $240,000 and ranging up to $288,000 per hydrogen fuel cell truck – Not too different if you take in the account of longer life span. Also, looking at cost of fuel, this maybe a mute point soon due to aggressive goals set by the US which aims to cut hydrogen fuel cost in half within the near future.

MCS Charging Station Challenges

Moreover, the megawatt charging stations for hydrogen fuel trucks aren’t without their challenges. For instance, they have different site requirements than those for passenger cars, as they would need to have enough space for considerably larger vehicles while still being at a point in the grid able to support at least 10MW of power.

In conclusion, both battery electric vehicles (BEVs) and fuel cell electric vehicles (FCEVs) offer potential solutions for reducing emissions and decarbonizing the transportation sector. Each technology has its own set of advantages and disadvantages, with BEVs providing higher efficiency, more affordable prices over time, and wider availability of charging stations, while FCEVs offer longer range, longer life, and greater payload capacity. The choice between these two options will ultimately depend on the specific needs and priorities of the user, such as range requirements, payload capacity, and available infrastructure. As technology continues to advance and the costs of both BEVs and FCEVs decrease, it is likely that both options will play a significant role in the transition toward more sustainable transportation systems worldwide.