China-based Dongfang Electric Corporation (DEC) reported successful testing of non-desalinated seawater electrolysis technology for hydrogen production powered by offshore wind.

The floating hydrogen production platform Dongfu One is sited in an offshore wind farm in East China’s Fujian province. This project was a joint effort by DEC and a research team led by Academician Xie Heping from the Chinese Academy of Engineering. A paper describing the project is published in Nature.

Electrochemical saline water electrolysis using renewable energy as input is a highly desirable and sustainable method for the mass production of green hydrogen; however, its practical viability is seriously challenged by insufficient durability because of the electrode side reactions and corrosion issues arising from the complex components of seawater. Although catalyst engineering using polyanion coatings to suppress corrosion by chloride ions or creating highly selective electrocatalysts has been extensively exploited with modest success, it is still far from satisfactory for practical applications.

Indirect seawater splitting by using a pre-desalination process can avoid side-reaction and corrosion problems, but it requires additional energy input, making it economically less attractive. In addition, the independent bulky desalination system makes seawater electrolysis systems less flexible in terms of size.

Here we propose a direct seawater electrolysis method for hydrogen production that radically addresses the side-reaction and corrosion problems.

—Xie et al.

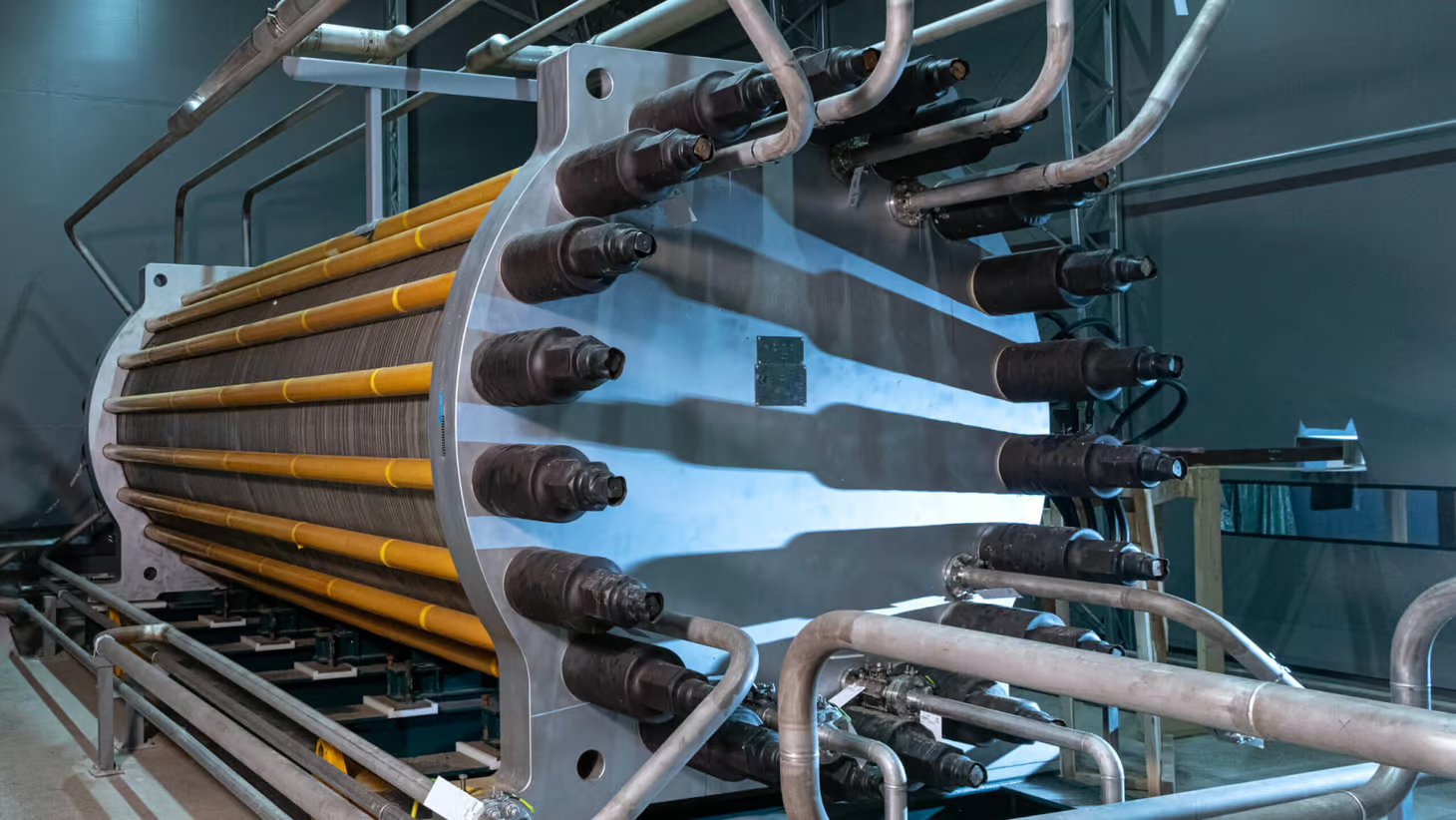

Dongfu One integrates on-site hydrogen production, smart energy conversion management, safety monitoring and control, as well as loading and unloading systems.

The partners said that the successful test validates the feasibility and stability of direct seawater electrolysis technology in a real ocean environment.