UK-based Rolls-Royce SMR and Sumitomo Corporation have completed a joint feasibility study which indicates that Rolls-Royce small modular reactors (SMRs) could offer a significant advantage for the production of low-carbon hydrogen.

UK-based Rolls-Royce SMR and Sumitomo Corporation have completed a joint feasibility study which indicates that Rolls-Royce small modular reactors (SMRs) could offer a significant advantage for the production of low-carbon hydrogen.The study analysed the use of both heat and power from the Rolls-Royce SMR to run electrolysers to produce low-carbon hydrogen. The detailed independent study was produced using real-world data and found that – when cost, availability and carbon emissions are taken into consideration – hydrogen production powered by a Rolls-Royce SMR has the greatest overall advantage compared with other available sources.

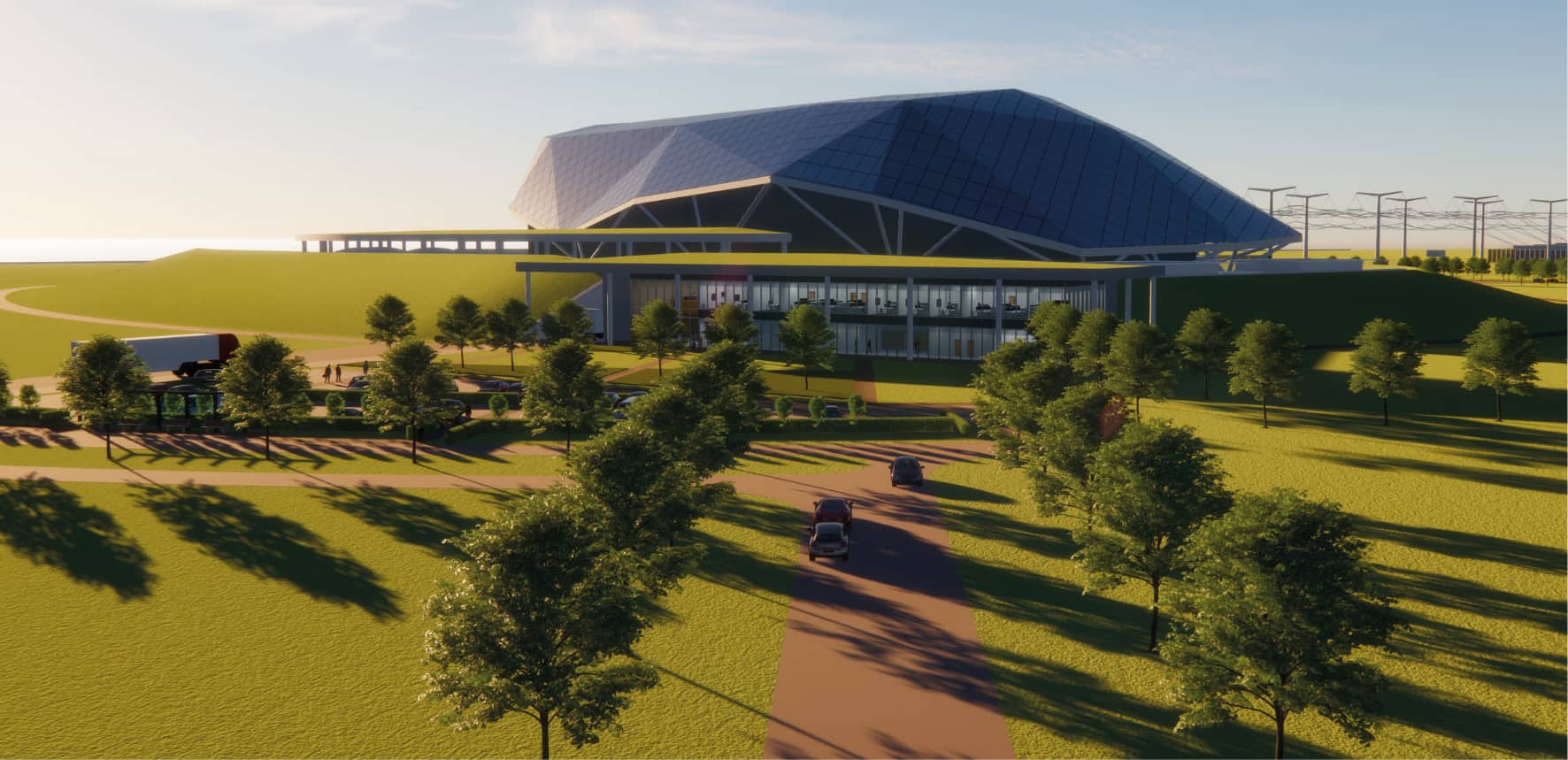

The 470MWe factory-built Rolls-Royce SMR design is based on a small pressurised water reactor. Its compact footprint and modular design means it can be located alongside energy intensive industrial processes – including hydrogen production. For the production of hydrogen via Solid Oxide Electrolytic Cell (SOEC) technology, it is possible to use the thermal output of the power plant to radically boost the overall efficiency of the hydrogen production cycle.The design in April completed the first step of the UK's Generic Design Assessment (GDA) process and is expected to complete the second step by July 2024.

Harry Keeling, Rolls-Royce SMR’s Head of Industrial Markets, said: “The potential for the Rolls-Royce SMR to be used for industrial purposes is one of its greatest strengths – being able to deliver large amounts of low-carbon, always-on power, but being flexible enough to be located close to where industry needs it. The production of low-cost hydrogen is a critical step on the pathway to decarbonising our wider society.”

Sumitomo Corporation will now use the report to support site suitability work and develop its understanding around the potential for utilising Rolls-Royce SMRs alongside clean hydrogen production facilities in the UK.