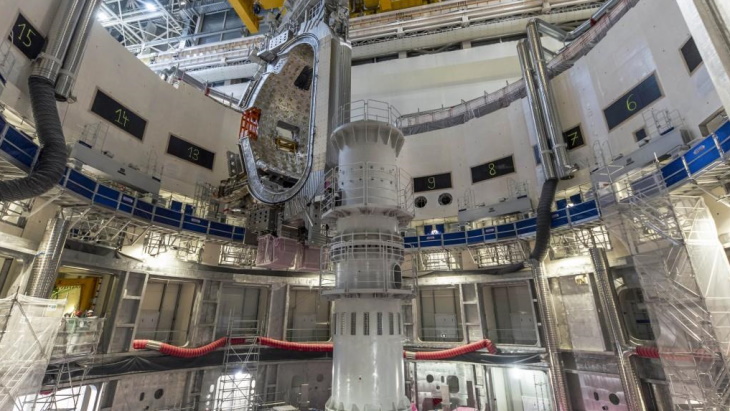

ITER's plasma chamber, or vacuum vessel, houses the fusion reactions and acts as a first safety containment barrier. It will be formed from nine wedge-shaped steel sectors that measure over 14 metres in height and weigh 440 tonnes. The sector sub-assembly tools - each about 22 metres in height and weighing around 860 tonnes - are designed to support the weight of one vacuum vessel sector, two toroidal field coils and silver-coated thermal shields, which together weigh some 1200 tonnes.

The first full sector subassembly - consisting of the double-walled vacuum vessel sector, a tightly fitted thermal shield and two D-shaped vertical superconducting electromagnets called toroidal field coils - was transferred from the Assembly Hall into the tokamak pit in May last year.

The ITER Organisation said the discovery of dimensional non-conformities in the vacuum vessel sector's welding joint region, together with corrosion-induced cracks in thermal shield piping, has meant that the component has been removed from the assembly pit and returned to the Assembly Hall for disassembly.

"Although not foreseen in the original specifications of the assembly tools, the reverse lift operation was performed with the same hardware successfully," ITER said.

It noted the reverse lift - an operation that took almost four days, excluding advanced preparation activities - did not simply consist of reversing what had been done more than one year before. Procedures had to be adapted and additional guiding systems had to be manufactured and installed.

The removal of the module began on 4 July with a "pre-lift" that raised the load a few centimetres from its landed position. For the main operation, more than one hundred different steps had been defined, validated and integrated into the lifting procedure - from detaching the module from its moorings in the assembly pit, to lifting and transporting it to the sub-assembly tool on the other side of the wall in the Assembly Hall. To carry out the planned succession of moves - lifting, rotating, advancing, rotating, advancing, lowering - it was essential to determine with utmost precision the relative position of each of the elements concerned: the load itself, the overhead crane's complex rigging and the tool support systems at the receiving end.

"The module is of a composite nature," said ITER assembly engineer Daniel Coelho. "When sitting in the pit, the vacuum vessel and the toroidal field coils are not mechanically connected. It's only during the lifting phase that, thanks to the bracing tools that attach vacuum vessel and coils together, they become one homogeneous load with a common centre of gravity.

"We have made considerable progress in terms of alignment accuracy and, what is also very important, we operated with the same team. Everybody knew his/her part perfectly, and coordination among the team members was smooth."

On 5 and 6 July, the actual lifting and landing took place of the module along the pit's central column, over the separating wall and its insertion into the sector sub-assembly tool.

Disassembly activities have already started in preparation for the synchronised opening of the tools' wings and the removal of the toroidal field coils, followed by the removal of the thermal shield panels. Preparation for repairs - starting with metrology to define the metal build-up and machining zones - will then begin.

The ITER vacuum vessel - with an interior volume of 1400 cubic metres - is unique: the volume of plasma it can contain (840 cubic metres) is fully ten times larger than that of the largest operating tokamak in the world today. The ITER vacuum vessel, once assembled, will have an outer diameter of 19.4 metres, a height of 11.4 metres, and weigh approximately 5200 tonnes. With the subsequent installation of in-vessel components such as the blanket and the divertor, the vacuum vessel will weigh 8500 tonnes.

ITER is a major international project to build a tokamak fusion device in Cadarache, France, designed to prove the feasibility of fusion as a large-scale and carbon-free source of energy. The goal of ITER is to operate at 500 MW (for at least 400 seconds continuously) with 50 MW of plasma heating power input. It appears that an additional 300 MWe of electricity input may be required in operation. No electricity will be generated at ITER.

The current timeline for ITER is for first plasma in 2025 and the start of deuterium-tritium operation in 2035, but that timeline is being revised. Last month the ITER Organisation was expected to reveal the revised timeline for the project but instead put back by a year an announcement on an updated timeline.

Researched and written by World Nuclear News