The successful completion of testing of Hyzon’s nine 200kW FCS B-samples in the first half of 2023 demonstrates consistent progress toward commercial production. This achievement follows the commissioning of Hyzon’s proprietary, automated roll-to-roll Membrane Electrode Assembly (MEA) production line including in-line inspection and the installation of its single cell and fully automated fuel cell stack manufacturing lines.

Progression of the 200kW FCS B-samples validates the design, equipment, and operating procedures, which are all critical to the final tooling and production of C-samples and the eventual commercialization of the FCS. Additionally, Hyzon believes it shows growth in the company’s prototype assembly rate, with six of the B-samples produced and tested in Q2 2023, an increase from three in Q1 2023.

Hyzon is positioning to increase its FCS manufacturing rate with the installation of additional full and semi-automation equipment in the assembly and inspection processes, which is already underway. Hyzon also expects the continued standardization of design around the 200kW FCS powertrain components will expedite production and the company expects the remaining 16 B-samples to be complete and the production of C-samples to begin in the second half of 2023.

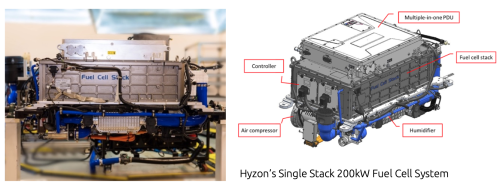

Hyzon’s single-stack 200kW FCS provides significant advantages relative to current industry standards. While most FCEV suppliers achieve 200kW output by coupling two ~110kW FCSs, Hyzon has developed proprietary material, design, and equipment engineering enabling 200kW output from a single stack. This is expected to result in the following improvements:

~20% increase in miles per kilogram of hydrogen vs the 120kW FCS – greatly improving the truck total cost ownership (TCO);

~30% smaller volume & weight;

25% lower cost; and

Materially less maintenance than two 100kW long-range fuel cell systems due to the relative simplicity of design.