EPFL engineers in Sion, Switzerland have demonstrated the potential for achieving net-zero and net-negative emissions in essential industrial sectors through the integration of carbon capture and mineralization directly in the industries themselves. The research focuses on the strategic sectors of cement production, steel manufacture, and waste incineration. It offers a cost-effective and energy-efficient approach to mitigate CO2emissions, thereby contributing significantly to reaching global climate targets

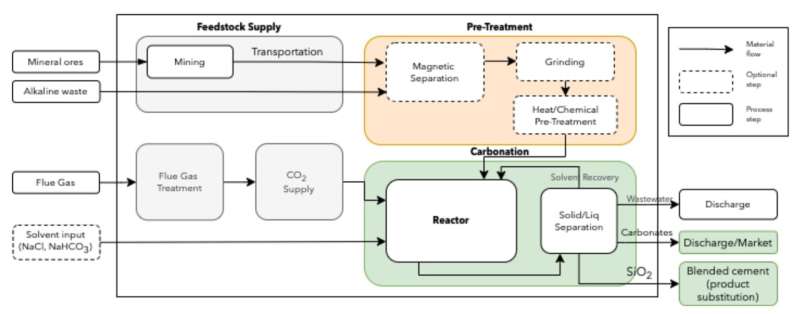

With the urgent need to address carbon emissions from factories and industrial facilities, the research from the Laboratory of Industrial Process and Energy Systems Engineering (IPESE) introduces a solution to integrate CO2 capture and mineralization within the production process.

The carbonates formed through mineralization provide a safe and long-term storage solution for CO2, effectively removing it from the atmosphere. As a further ecological benefit, the mineralized carbon can be used as a building material. This, in turn, preventing the extraction of new materials and contributes to reduced emissions and a circular economy.

According to Professor François Marechal, head of IPESE, these key industrial sectors need CO2 capturing to reach carbon neutrality.

"Reaching net-zero cannot be done by replacing fossil fuels with renewable energy alone. In this study we demonstrate the importance of adopting a process integration to reduce the cost of the capture and of the sequestration," says Marechal. According to the research, mineralization, or achieving the ultimate oxidation state for carbon, guarantees a safe and long-term sequestration and solves the problem of finding deep geological locations for sequestration.

Reusing materials found nearby and on site

EPFL's research by Ph.D. student Rafael Castro-Amoedo applies a systems engineering approach that integrates capture and mineralization directly within the industrial sectors themselves, taking advantage of their large amounts of waste heat, alkaline solid residues, and process emissions. These sectors currently represent approximately 12% of all EU emissions, and the carbon could be sequestrated at a cost of 62 and 85 EUR per ton of CO2.

The costs detailed in the study offering economic benefits of up to 50% over deploying capture and storage separately and highlight the importance of applying a process system integration. Environmentally, applying this methodology would amount to a reduction of 860 million tons of CO2 and represents savings of 535 billion EUR when compared to the overall social costs of inaction. Put into context, these savings would total around 130 EUR per year for each European citizen.

The successful implementation of this transformative solution would require a significant retrofitting effort across industries. The research shows that a six-year timeline is necessary to retrofit existing facilities and fully integrate the proposed carbon capture and mineralization technology. This timeframe would allow for the gradual transition of industries towards a more sustainable and climate-friendly future.

The research is published in the journal Energy and Environmental Science and represents a significant step towards achieving net-zero and net-negative emissions in industrial sectors.

By capturing CO2 directly from factories, utilizing waste residues, and integrating external minerals, this innovative approach offers a cost-effective, energy-efficient, and environmentally sound solution. The economic benefits and potential cost savings associated with Amoedo's integrated solution make a compelling case for increased policy measures and carbon pricing reform. With continued support and collaboration, this research holds the potential to revolutionize industrial practices, mitigate climate change, and pave the way for a sustainable future.