As its pre-mixed combustion results in low NOx emissions, the ME-GA engine is inherently Tier II and Tier III compliant in gas-operation mode. To utilize its dual-fuel potential in Tier III areas fully, the engine is being offered with Exhaust Gas Recirculation (EGR) that reduces methane-slip emissions compared to first-generation, Otto-cycle engines without EGR.

This successful gas trial is a very important milestone in the development of the ME-GA engine. We developed this engine for easy application to most contemporary LNG carrier designs and, indeed, all ME-GA orders to date have been exclusively for this segment.

—Bjarne Foldager, Head of Two-Stroke Business, MAN Energy Solutions

We have had more than 260 orders for the ME-GA since its launch in May 2021 and our orderbook contains ME-GA engine orders for ship deliveries stretching all the way into 2027. EGR as standard enables the ME-GA to significantly reduce emissions, while simultaneously improving fuel efficiency and operation in both gas and fuel-oil operation.

—Thomas S. Hansen, Head of Promotion and Customer Support, MAN Energy Solutions

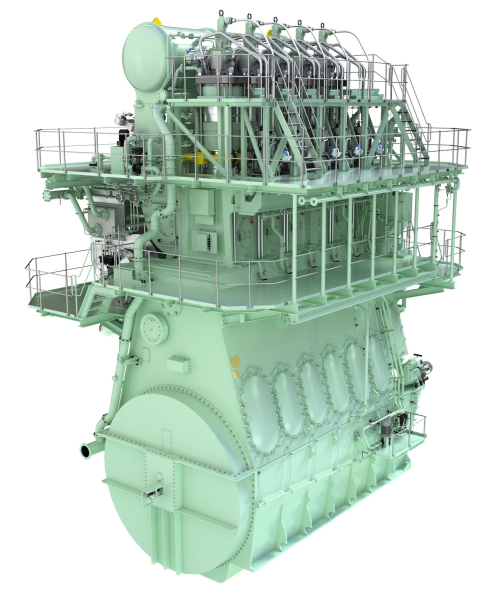

The MAN B&W ME-GA engine delivers a low CAPEX solution aimed at LNG carriers that are able to use boil-off gas as a source of fuel.

Based on the well-proven MAN B&W dual-fuel design with minimal installation requirements, the MAN B&W ME-GA uses an efficient ignition concept and unique gas-admission system that delivers safe and reliable operation.

The ME-GA furthermore features minimal operational costs, simple supply and purging concepts, and low maintenance costs for its fuel-gas supply system. It joins the well-established ME-GI Diesel-cycle engine in MAN Energy Solutions’ two-stroke-engine portfolio, which now offers both low- and high-pressure, dual-fuel solutions for operation on LNG.