The soaring price of energy following Russia’s invasion of Ukraine combined with a growing willingness to explore alternative energy sources is motivating many countries to look for solutions within their own borders.

The soaring price of energy following Russia’s invasion of Ukraine combined with a growing willingness to explore alternative energy sources is motivating many countries to look for solutions within their own borders.And nations seem to be taking different, sometimes diametric, approaches. While Germany has just phased out its last three nuclear power stations with renewable energy as a replacement, the UK has chosen to inject extra funding into nuclear power stations in the name of energy independence.

The electricity provided by the UK’s £20billion nuclear power station project, Hinkley Point C, aims to power around six million homes and will take 10 years to complete.

The project is huge, with around 5,000 people working on it daily, although it could go up to 10,000 on a particular day, with about 50 cranes working concurrently.

“On a project of this scale, you would never be able to do anything with just paper,” says quality systems engineer at BYLOR, Alina Turda.

BYLOR is a joint venture between construction companies Bouygues Travaux Publics and Laing O’Rourke and is behind the main engineering work at Hinkley Point C.

The venture is using industrial technology firm Trimble’ products to apply to this mammoth project and, according to the manufacturer’s BIM strategy and partnerships manager, many of the issues involving interoperability more generally in construction have been resolved on the Hinkley Point C project.

Digitalising pen and paper

The project took on Trimble’s ‘Viewpoint’s Field View’ product – a cloud-based mobile solution created to replace pen and paper – to use in the field for forms, defect management, project delivery, and handover processes.

The digitalisation meant that those onsite could capture and document while in the field, rather than taking the length of time to return to the office to process it there.

“Given the size of the project, not everyone can be at the work front looking at what’s physically happening. As a result, the ability to move that information into a digital dashboard is useful,” explains Greg Bond deputy joint project office lead at BYLOR.

Bond adds that the platform also allows the process to be completely transparent to the clients. “I think on most construction projects, you’d be used to hiding your quality records away from your client until you’d crossed all the T’s and dotted the I’s,” admits Bond.

“Now, clients are very active in monitoring and checking,” he adds, “and this kind of openness and transparency has definitely led to a very positive relationship.”

Although many long-term workers in the engineering industry found it a challenge to take on the digital work processes, many of them came on board as they realised the benefits.

“Some of these people have never used anything but paper, so it was difficult to convince them,” says Tim Davies, digital engineering lead at BYLOR, “but with the help of the leaders in each area we got there eventually – to the point where today we are overwhelmed with the number of requests from them to digitise all their pieces of records.”

“I think generally, if you’re offering someone a tool which is going to make their life easier, the rate of adoption and enthusiasm is often higher than you think,” he adds.

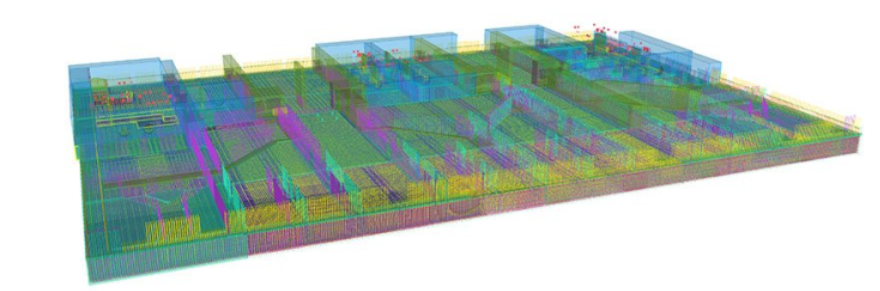

3D models

As a part of the Trimble Field View, engineers can also access 3D models on a tablet to help with what they are about to build, in replacement of paper 2D sketches.

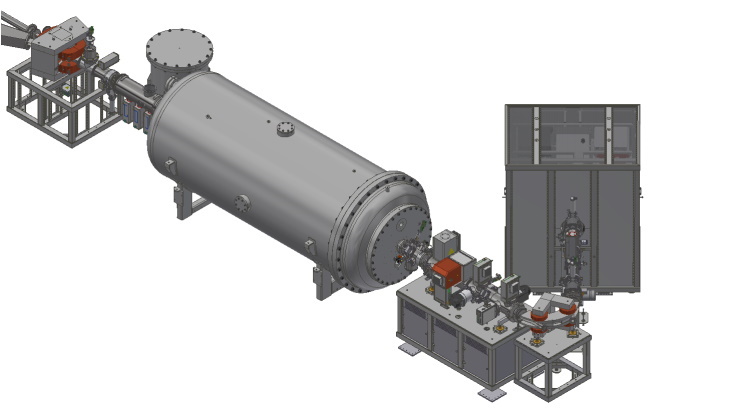

A 3D model for Hinkley Point C

“Building the majority of our civil engineering works from the 3D models as opposed to 2D drawings has benefits, especially on this project, as it’s allowed us to understand the complexity much more,” adds Bond.

This has helped construction workers understand the building process better according to Bond, who adds that the 3D models, alongside data capture, can also speed up the process by resolving any concerns.

For instance, Hinkley Point C is expected to use 220,000 tonnes of reinforcement and about 1.3 million cubic metres of concrete in its construction.

With this, BYLOR used Trimble’s documentation system to create a unique ID code for every single concrete pour.

One day, an observant engineer found that the 2D drawing and a 3D model did not quite agree on the amount of concrete that had to go into a concrete pour after many had already occurred.

After it was raised, the employees had to check each pour and create an action plan using the digital documents and 3D models.

“If we were still in a paper-based world, we would have had a group of engineers and dock controllers go through 10,000 records and it would have potentially taken us weeks,” said Bond.

Fortunately, with the data they already had, they were able to remedy the issue in two to three hours.