Oilfield services provider Baker Hughes has signed a memorandum of understanding (MoU) with airport management and operations firm Avports to develop on-site, hydrogen-fueled microgrids at airports. Avports wants to focus on improving power resiliency and decarbonization at airports, while Baker Hughes says it could provide hydrogen-ready turbines and heat recovery solutions for on-site cogeneration plants that reduce greenhouse gas emissions.

Baker Hughes’ origin as an oil industry tool and drilling services firm dates back more than a century and now involves drilling operations in dozens of nations. In recent years, like numerous oil and gas industry firms, the company has announced carbon capture and other decarbonization initiatives such as reducing emissions 50% by 2030 and a goal of to net zero by 2050.

Airport microgrids are becoming another avenue to achieve carbon-free goals in the transportation industry. Airports such as Pittsburgh International in Pennsylvania and JFK in New York have completed or are in construction on renewable and gas-fired generation microgrids.

Under the MoU, Baker Hughes and Avports could collaborate around facilities managed and operated by the latter. Avports’ work supports such airports as Albany International, MidAmerica St. Louis, Los Angeles-Tom Bradley Terminal at Los Angeles International and Westchester Airport in New York, among others.

"Providing a technical and economic road map to airports to meet their energy needs of the future is key as an airport management and operations company," said Jorge Roberts, CEO of Avports, in a statement. "Our partnership with Baker Hughes brings world-class technology and know-how together with our ability to support airport customers to realize these solutions at their facility."

In May, Baker Hughes announced a collaboration with Abu Dhabi petrochemicals group ADNOC focused on new technologies for accelerating development and commercialization of low-carbon hydrogen and graphene. This follows earlier investments by Baker Hughes in methane pyrolysis and next-generation electrolysis breakthroughs. Pyrolysis is a thermal breakdown of methane gas to provide hydrogen.

“Collaboration is crucial to supporting and accelerating the growth of low-carbon energy resources,” Baker Hughes CEO Lorenzo Simonelli said at the time of the ADNOC announcement.

Hydrogen is the lightest energy-dense gas that does not contain carbon in its chain and so does not emit CO2 when combusted. It also can be separated from methane natural gas via steam reforming, but that is a carbon-intensive process unless the carbon is captured and stored underground.

Hydrogen is not naturally mined or produced, but it also can be generated via electrolysis, which uses an electrical processes to split the H2 from water. To be truly “green hydrogen,” the electrolyzers would have to be powered by carbon-free electricity resources such as solar, wind, hydro, battery storage or nuclear.

Baker Hughes previously announced it is also working with HIF Global on direct air carbon capture technology in the attempt to further remove greenhouse gas emissions from fossil fuel generation and hydrogen production.

The company has developed several projects utilizing hydrogen for numerous industries. Its leaders see a bright future in the aviation sector.

“The opportunity to bring these solutions to airports, in collaboration with Avports’ proven track record in airport management, is very promising as the increasing needs and demands of these infrastructures must be more resilient, efficient and cost-effective,” said Bob Perez, vice president of project development at Baker Hughes.

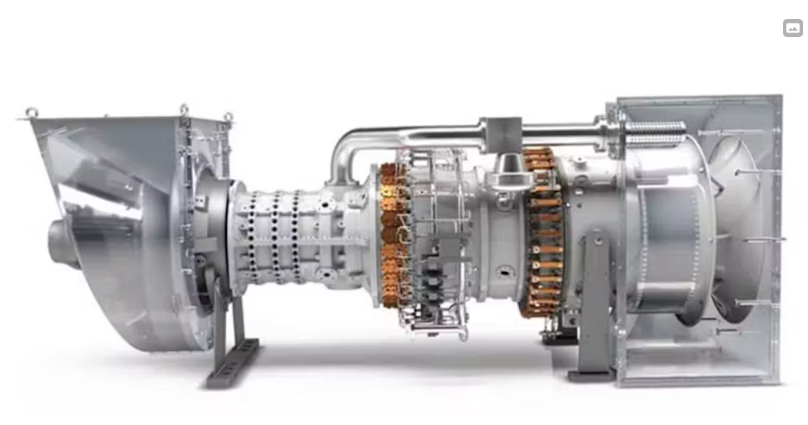

In 2020, Baker Hughes announced and it and Snam had successfully completed testing in Italy on a hybrid natural gas turbine blended with hydrogen. The tests on Baker Hughes' NovaLT12 gas turbine (pictured above) started with a 10% mix of H2.