A new company, called Hadean Energy, will trial the cutting-edge technology at BlueScope’s Port Kembla Steelworks to demonstrate the equipment at pilot scale in an industrial environment before moving on to megawatt scale installations.

It’s one of a number of new green hydrogen technologies where efficiency – particularly in the amount of electricity used – is key. A University of Wollongong spin-off, Hysata, recently opened its first manufacturing facility at Port Kembla and is building its first 5MWh installation.

Electrolysers that use industrial heat and solid ceramic electrolytes are hard to scale, they degrade at high temperatures, and the long seals at the edges of the flat, square or rectangular shapes create a lot of opportunity for leaks.

But to date it’s one of the only options for industrial sites wanting to make use of waste heat, which would otherwise need to be expensively cooled, and waste steam, to make hydrogen or synthetic hydrocarbons.

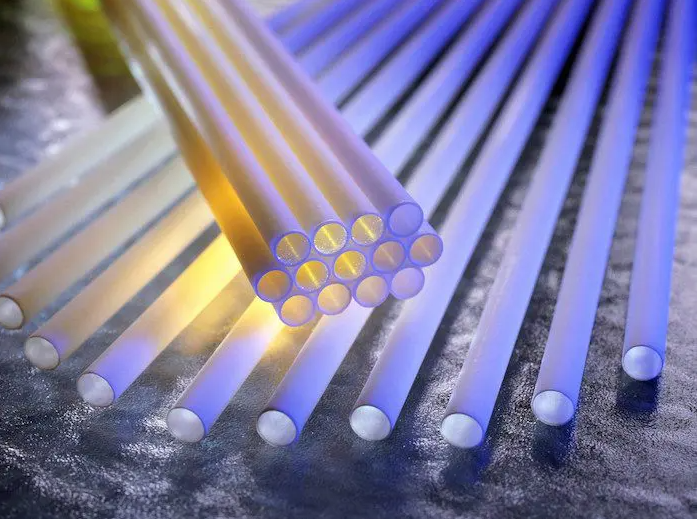

CSIRO researchers have spent the last seven years building an alternative: instead of flat squares, why not build tubes that only need to be sealed at each end?

The end result, a ceramic tube with electrodes on the inside and out, is deceptively simple. But the researchers, led by CSIRO hydrogen lead Dr Sarbjit Giddey, had to navigate a series of challenges before arriving at their first 250 watt system (flat squares are easy to build – tubes are not).

The test its first kilowatt-scale unit at Bluescope Steel’s Port Kembla steelworks will continue for four months next year. In the meantime it is working on scaling the manufacturing process to build a megawatt-scale unit.

In five years the company wants to be building and selling multi-megawatt units, says Dougal Adamson, an executive at RFC Ambrian.

Uses hot heat and cool heat

The tubular solid oxide electrolysis (SOE) technology uses steam from industrial processes to split into oxygen and hydrogen, and industrial process heat to bring down the energy levels needed to break the molecules apart and therefore the cost of making hydrogen, or synthetic gases by splitting carbon dioxide molecules.

Electrodes inside and outside the tube provide the power to split the molecules. The ceramic material allows the oxygen ions to escape while retaining the hydrogen.

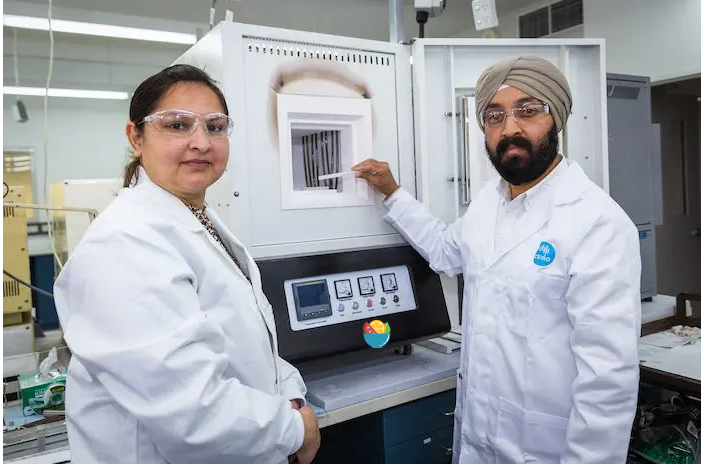

Image: CSIRO. Dr Gaurpreet Kaur, who refined the system, and lead hydrogen researcher Dr Sarbjit Giddey, with a high temperature furnace for tempering the tubes.

They say that at 800°C the system uses 30 per cent less electricity, or about 40 kilowatt hours (kWh) per kilogram of hydrogen than a proton exchange membrane (PEM) electrolyser or an alkaline system, which uses about 55 kWh/kg of hydrogen.

At “low quality” heat, that is around the 200-300°C mark, it is 20 per cent more efficient, Adamson says.

“In terms of fundamental research, the cell itself that CSIRO has developed is seriously good, so the fundamental science is excellent and industry-leading. What Hadean is doing is that next step of engineering and making it a usable, commercial product for industry, something that is safe and durable and scaled,” he says.

The new system could be useful for both levels of heat.

It means companies with superheated steam can skip the extra step of putting it through a turbine to then power a PEM electrolyser, Adamson says.

And because of the embedded heat in steam, it means low quality heat which is otherwise not useful and must be cooled using chillers is still effective using this system.

Giddey says the tech allows industrial waste heat to be integrated back into industrial processes, which also eliminates storage and transport costs and therefore fossil fuel use in the industrial process.

Stacking up against squares

What this system is up against are square planar ceramic electrolysers, made by the likes of Bloom Energy and Sunfire in the US.

Giddey says the Hadean system is simpler and easier to stack together in order to scale the size up, and the CSIRO-designed manufacturing process is also simpler than for the planar options which require comparatively extensive sealing around the edges using the likes of glass.

Planar systems offer better cell-level performance due to their structure, but sandwiching the cells together means it’s difficult to manage stresses throughout the stack which means leakage starts as seals degrade faster, Adamson says.

He says the Hadean cells work as well but have the advantage of only needing 2cm of sealant for the same active area, compared to 120cm.