All-solid-state lithium–sulfur batteries (ASSLSBs) are considered one of the most promising next-generation energy storage devices for high energy density, high safety, and low cost of sulfur.

Recently, researchers led by Prof. Wu Jianfei from the Qingdao Institute of Bioenergy and Bioprocess Technology (QIBEBT) of the Chinese Academy of Sciences have made a breakthrough in defect engineering and performance improvement of ASSLSBs.

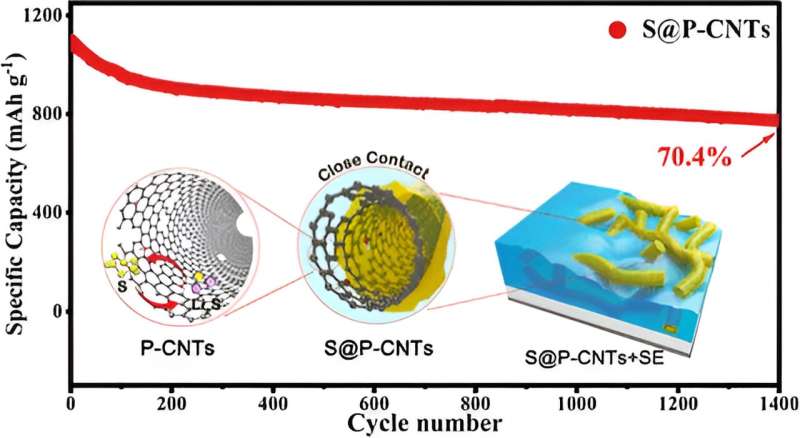

They prepared porous-carbon nanotubes (P-CNTs) that are used as sulfur-bearing matrix, forming S@P-CNTs-based composite cathodes for ASSLSBs. P-CNTs acted as a mediator and established a stable triple phase between sulfur, P-CNTs, and ionic conductor solid-state electrolyte (SSE) Li6PS5Cl. The study was published in ACS Applied Materials & Interfaces on Aug. 18.

Through designing defects and increasing active sites on the surface of P-CNTs, sulfur was uniformly encapsulated on the inner and outer surfaces of the activated P-CNTs. The reaction activity and stability of the sulfur cathode in the ASSLSB could be substantially improved by optimizing the ion and electron transport networks.

The researchers proved that the migration of lithium ions at the interface between P-CNTs and SE was easier, benefiting the coulombic efficiency and cycle stability of the ASSLSB.

The S@P-CNTs-based ASSLSBs displayed capacity of 1,099.2 mA h g-1 at current density of 1.34 mA cm-2 and 1.5 mg cm-2 sulfur loading and maintained 70.4% of the initial capacity over 1,400 cycles.

The SSE developed by the group can provide good charging and discharging performance for batteries even under -40 °C. The capacity of soft pack all-solid-state batteries (ASSBs) using this electrolyte can maintain 82.7% capacity after cycling 3,000 times at 25 °C and 0.5 °C, which initially solves the life-span problem of sulfide ASSBs.

"Our work provides a new strategy for the microstructural engineering of carbon materials and interfacial modification for high-performance ASSLSBs," said Prof. Wu.